Charcoal Grinder Machine for Making Fine Charcoal Powder

Lump Charcoal Grinder | Coal Grinding Machine

Charcoal Grinder Machine for Making Fine Charcoal Powder

Lump Charcoal Grinder | Coal Grinding Machine

Features at a Glance

The lump charcoal grinder machine also known as a charcoal briquette grinder(charcoal powder crusher), is a kind of coal briquette crushing equipment that is composed of grinding lead and a rolling plate.

The wheel-type charcoal powder grinding machine has a pair of grinding blocks and a rolling plate. When crushing the lump of charcoal & coal briquettes, it is crushed by the grinding block on a rotating rolling plate. There are sieve holes in the outer ring of the roller, and the crushed materials are discharged from the sieve holes.

Why do the lump charcoal briquettes need to be crushed?

We all know that charcoal products are very popular in the international market now. We use charcoal for heating and cooking and especially for a barbecue with our family and friends. In addition, charcoal also can be used in activated carbon production, and the cosmetics industry and it can be formed into many beautiful shapes for special usage. But the charcoal briquettes should be crushed before they are processed into other shapes.

In the mixing process, the charcoal grinder machine can not only stir but also crush, which can remove the air between the material particles, make the water of the mixed material even, the surface of the particles wet enough, and the mixing effect is good.

The charcoal briquettes crusher machine is suitable for mixing granular materials, such as refractory mud, clay, fly ash, tailing sand, slag, charcoal powder, etc. Widely used in the production of unfired bricks, refractory materials, ceramics, building materials, and other industries.

-

charcoal-crusher-machine-1 -

charcoal-crusher-2 -

wheel-charcoal-grinding-machine-3 -

coal-briquettes-grinding-machine-4 -

charcoal-briquettes-grinder-machine-6 -

wheel-grinding-machine-7 -

wheel-charcoal-grinding-machine-8 -

charcoal-crusher-machine-9

Charcoal grinder machine working principle

The charcoal powder grinding machine has many models, and each model has a different working capacity so that you can choose at your will. The height of the wheel can be automatically adjusted. When processing a large or hard material, the rolling wheel can automatically rise to cover the hard materials due to its gravity and automatically fall.

When the lump charcoal grinder machine is working, the disc is fixed while the two wheels revolve around the main shaft on the coal briquettes grinding machine disc. Meanwhile, the wheel rotates on its horizontal axis under the action of the friction of materials, which can increase the stressed area of materials and make the materials in the machine be crushed and stirred sufficiently.

Wheel charcoal grinder machine technical parameters

| Diameter (mm) | 1000 | 1200 | 1440 | 1600 | 1800 | 2000 | 2500 |

| Capacity(Kg/h) | 110 | 150 | 200 | 350 | 550 | 900 | 1700 |

| Mix time( min) | 3-8 | 3-5 | 3-5 | 2-5 | 3-5 | 2-5 | 2-5 |

| Speed(r/min) | 41 | 41/27 | 24 | 40 | 36 | 35 | 30 |

| Power(KW) | 4 | 5.5 | 7.5 | 15 | 18.5 | 22 | 37 |

Features of the charcoal briquettes crushing and mixing machine

- The coal powder grinding machine’s structure is simple, easy to manufacture and maintain, and the size requirement of the feed material is not strict. The crushing and stirring effect of the material is good.

- Running smoothly, low power consumption, no shock vibration, wide application.

- The good mixing effect, high production efficiency, convenient discharge, easy cleaning, and the equipment is not easy to wear.

- It can be matched with a belt conveyor and double shaft mixer so that can realize the automatic production of charcoal briquettes.

- With the main functions of mixing and grinding, this charcoal machine can be widely used in charcoal production lines and coal ball production lines.

Charcoal grinder machine video

Hot Product

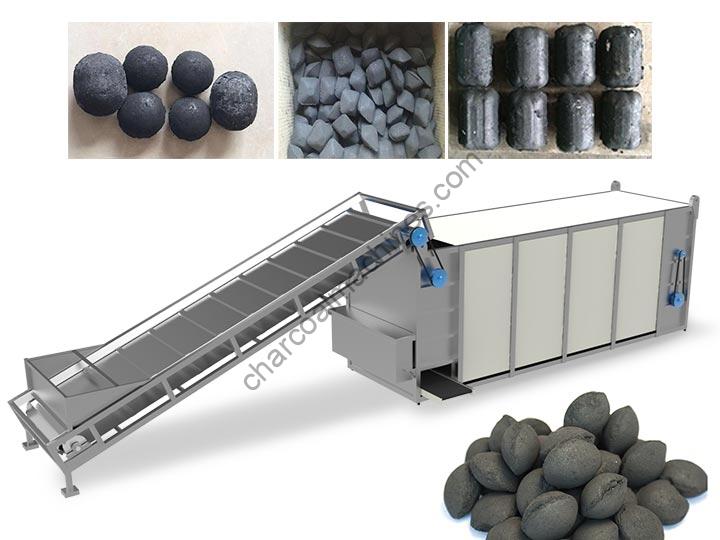

Wood Sawdust Briquettes Production Line | Pini Kay Heat Logs Plant

The wood sawdust briquettes production line mainly extrudes…

Charcoal Machine & Production Line for Making BioCharcoal

The charcoal making machines can turn biomass wastes,…

Thermal Shrink Packing Machine for Packaging Sawdust Pini Kay Briquettes

This automatic thermal shrink packing machine can be…

Disc Wood Chipper for Household Use

The small disc wood chipper can process logs,…

Compressed Wooden Pallet Production Line

The compressed wooden pallet production line is a…

Continuous Dryer for Drying Sawdust & Rice Husk

Industrial sawdust dryers and rice husk drying machines…

Charcoal Coal Crusher | Charcoal Powder Grinder Machine

The charcoal crusher machine can mainly pulverize various…

Compressed Wood Pallet Machine for Molded Pallet Production

The compressed wood pallet machine is a piece…

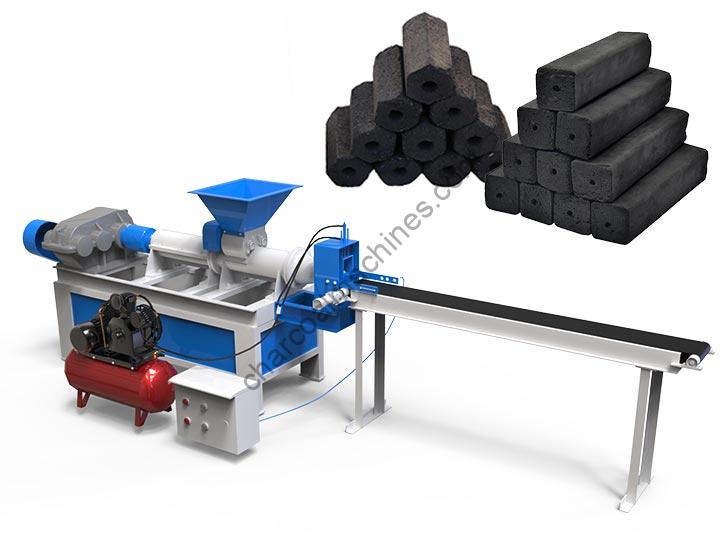

Hookah Charcoal Machine to Make Round & Cube Shisha Charcoal

Shuliy shisha charcoal press machine is designed according to…

No Comments.