İyi Performanslı Parti Kömür Kurutma Makinesi

Kömür Kurutucu | Briket Kurutma Makinesi

İyi Performanslı Parti Kömür Kurutma Makinesi

Kömür Kurutucu | Briket Kurutma Makinesi

Özellikler Hızlı Bakış

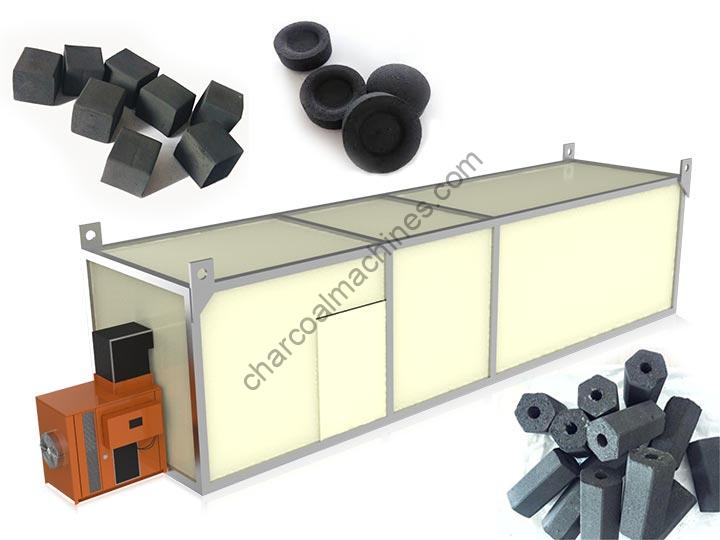

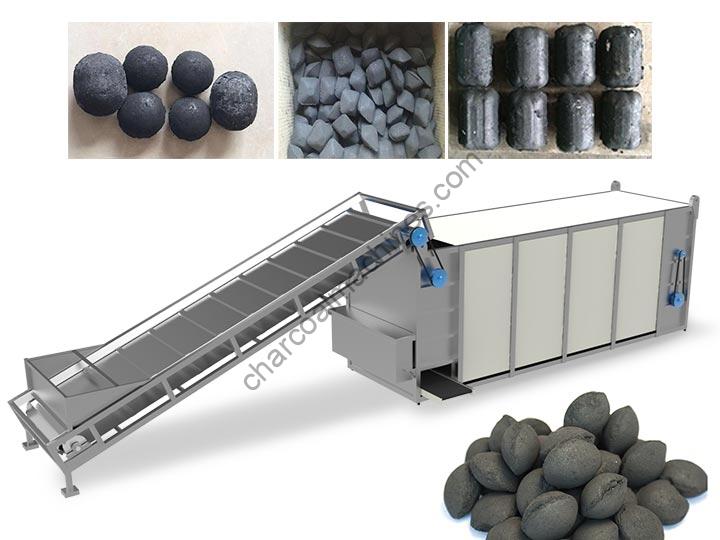

Kömür Kurutucu, her türlü kömür briketini, örneğin shisha kömürü, nargile kömürü, mangal kömürü briketleri gibi kurutmak için kullanılır. Bu endüstriyel kömür briketleri kurutma makinesi çeşitli ısıtma yöntemleri benimseyebilir ve kullanımı çok pratiktir. Kömür kurutmanın yanı sıra, tüm meyve, sebze, et vb. kurutmak için de kullanılabilir.

Nargile kömürü kurutucu veya mangal kömürü kurutucu, shisha/nargile kömürü veya mangal kömürü briketlerinin hızlı kurutulması için ideal ekipmandır, aynı zamanda kömür kurutucu kutu veya kömür kurutma odası olarak da adlandırılır. Kömür kurutucu makinesi, büyük miktarda kömür üretimi için çok uygundur.

Ayrıca, bu kömür kurutma makinesi 304 paslanmaz çelikten yapılmıştır, böylece tarih, biber, havuç, fasulye, sarımsak, longan, agarik, hawthorn, mantar gibi tüm meyve ve sebzeleri kurutmak için de kullanılabilir.

Ayrıca, krizantem, limon, gül gibi aromalı çay malzemeleri ve ginseng gibi Çin bitkisel ilaçlar da bu kurutucu makine ile kurutulabilir.

Kömür briketleri kurutucu makinesinin tanıtımı

Bu kutu tipi kömür briketleri kurutucu, yüksek nemli malzemeleri uygun nem seviyesine kurutmak ve malzemenin maksimum kullanım değerini sağlamak için tasarlanmıştır. Kurutucu, kömür veya kömür topu, shisha veya nargile kömürü briketleri, kömür briketleri gibi malzemeleri kurutmak için yaygın olarak kullanılır.

Bu kömür kurutucu, tamamen kapalı bir yapıya sahiptir ve sıcak hava kutuda dolaşır, bu da malzemelerin kuruma süresini kısaltır ve ürün kalitesini sağlar.

Genellikle, kurutucu makinesi malzemelerin nem içeriğini yaklaşık @'tan %8'e düşürebilir ve bu işlem yaklaşık 7-8 saat sürer. Ayrıca, makine kolay kurulum, pratik sökme ve taşıma özelliklerine sahiptir ve az yer kaplar.

Kömür kurutucu makinesi videosu

Kömür kurutucu makinesinin çalışma prensibi

Şişe kömürü kurutucu kurutucu dış kısmı özel olarak üç katmanlıdır. Dış malzeme galvanizli çelik levhadan, iç malzeme ise poliüretan olup, iyi ısı yalıtımı ve ısı koruma etkisi sağlar.

Sıcaklık kontrol sistemi iki tip olarak tasarlanabilir: biri birkaç düğmeyle güç ve iç sıcaklığı kontrol eden basit elektrik dolabı; diğeri ise PLC kontrol ekranı ile otomatik kontrol için çok uygundur.

Kurutma kutusunun dışında, sıcak hava üretmek için bir ısı pompası vardır. Kurutucu makinenin iç yapısı fan, özel kurutma arabaları ve kurutma tepsilerini içerir.

Bu kurutucu makinede fan, iki tipte de mevcuttur: biri sıcak havayı odanın içine eşit şekilde üflemek için, diğeri ise her zaman odanın üstünde malzemelerin nemini almak için ayarlanmıştır.

Kuruma arabası, sadece katmanlar ve tekerlekler içeren çok basit bir çerçevedir ve kurutma odasında kolayca hareket ettirilebilir. Kurutma tepsileri her zaman paslanmaz çelikten yapılmıştır, bu nedenle shisha kömürü veya mangal kömürü briketleri kurutulurken çok uygundur çünkü paslanmaz çelik kömür kurutulurken kömür tarafından yapışmaz.

Kömür Kurutma Makinesinin Ana Avantajları

- Kömür kurutucu makinesi, yapısı basit ve kurulumu kolaydır. Boyutu, müşterilerin çıktı taleplerine göre özelleştirilebilir.

- İç kurutucu odanın sıcaklığı, malzemenin nem içeriğine göre ayarlanabilir ve ayarlanabilir.

- Kurutucu odası duvarları ısı yalıtım levhasından yapılmıştır ve iç ısı yalıtım pamuk malzemesi çok özeldir, bu da ısı yayılımını etkin şekilde azaltabilir.

- Shisha/nargile kömürü ve kömür veya kömür topu kurutmanın yanı sıra, bu kurutucu makine büyük ölçekte meyve ve sebze kurutmak için de kullanılabilir.

- Düşük yatırım, hızlı kuruma hızı ve yüksek buharlaşma yoğunluğu. Yüksek çalışma verimliliği, büyük çıktı ve iyi ürün kalitesi.

Kömür kurutucu makinesi teknik parametreleri

| Model | Boyutlar (mm) | Sıcak hava fanlarının sayısı (1 set/0.58KW) | Nem alma fanlarının sayısı (1 set/0.12KW) | Çekişli fan (1 set/0.37KW) | Kuruma arabaları (grup) | Kuruma miktarı (her seferde/kg) |

| SL-2 | 4000*1600*2500 | 4 | 2 | 1 | 2 | 600 |

| SL-4 | 6000*1600*2500 | 4 | 2 | 1 | 4 | 1200 |

| SL-6 | 7200*2300*2500 | 6 | 2 | 1 | 6 | 1800 |

| SL-8 | 8800*2300*2500 | 6 | 2 | 1 | 8 | 2400 |

Kömür kurutucu makinesi, kömür briketleri işleme tesisinde

Sıcak Ürün

Duman Gazı Arıtma Ekipmanları

Duman gazı arıtımı Geçmişte, çünkü…

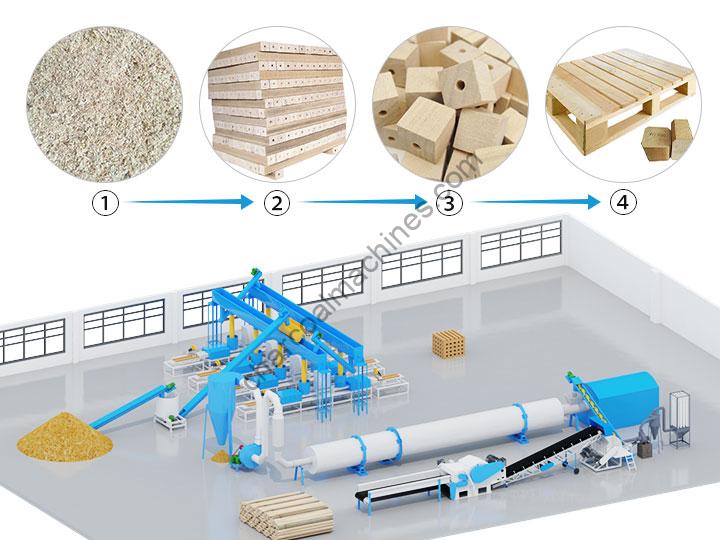

Kompresli Ahşap Palet blokları yapmak için Ahşap Blok Üretim Hattı

Odun blok üretim hattı yüksek kaliteli sıkıştırılmış…

Toz ve Pirinç Kabuğu Kurutmak için Sürekli Kurutucu

Endüstriyel testere tozu kurutucuları ve pirinç kabuğu kurutma makineleri…

Ahşap Çapaklarını Geri Dönüştürmek için Ahşap Çekiçli Makine

Ahşap çekiç kırıcı değirmeni, odun parçalarını kırabilir,…

Tüm Ahşap Atıklarından Toz Yapmak için Ahşap Kırıcı

Ahşap kırıcılar, yaygın olarak kullanılan parçalama ekipmanlarıdır…

Kompresli Ahşap Palet Makinesi Kalıplı Palet Üretimi İçin

Sıkıştırılmış ahşap palet makinesi, bir parça…

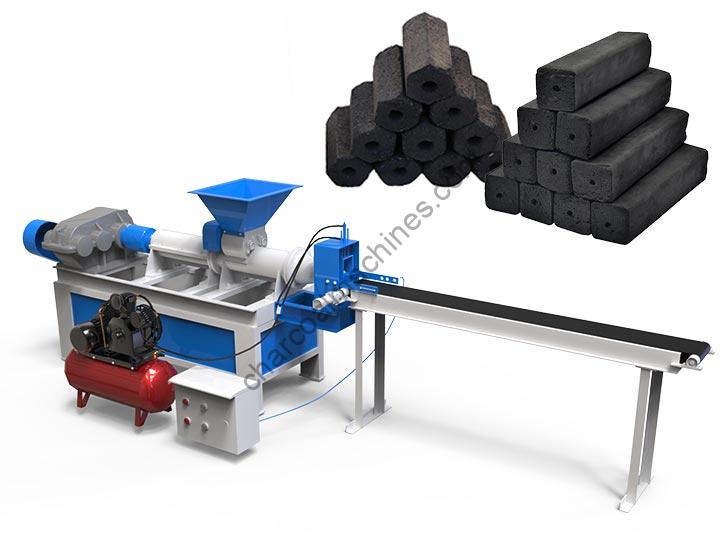

Kömür ve Kömür Tozu Kırıcı | Kömür Tozu Öğütücü Makinesi

Kömür kırıcı makinesi, çeşitli…

Kömür Kömürü Paketleme Makinesi ile Barbekü Kömürü Paketleme Makinesi

Bu kantitatif kömür kömürü paketleme makinesi, şu şekilde olabilir…

Kütük Soyma Makinesi

Ahşap soyma makinesi, aynı zamanda kütük…

5 yorum