Duman Gazı Arıtma Ekipmanları

Geçmişte, gelişmemiş bilim ve teknoloji nedeniyle, toprak fırınlarda odun kömürü yakımından çıkan duman gazı doğrudan havaya salınıyordu, bu da uzun süre hava kirliliğine neden oldu. Sosyal ekonomimizin gelişmesiyle, insanların çevre koruma bilinci artmakta, odun kömürü tesisleri ve fırın duman gazı arıtma ekipmanları kullanmak, çevre koruma emisyonlarını sağlamak zorunluluk haline gelmiştir.

Duman gazı arıtma ekipmanı toz ve karbonizasyon fırını ve makine yapımı kömür üretim sürecinde oluşan duman gazını büyük ölçüde azaltır. Duman gazı arıtıcı, büyük ölçekli makine yapımı kömür üretimi için gerekli çevre koruma ekipmanıdır, bu makine tasarım açısından makul, kurulumu basit olup, üretim sürecinde ideal makinedir ve esas olarak kömür üretim hattında kullanılır, karbonizasyon fırını ve fırın duman gazı arıtımında geniş çapta kullanılabilir.

Duman gazı arıtma ekipmanı Çalışma prensibi:

Silindirik tüp soğutucu kule ve soğutucu kule ile duman gazı arıtma, katmanlı çok katmanlı arıtma adım adım, engelleme ağı katmanı, destekler, dolaşımlı su borusu, toz tutucu, fan, katran toplama ağzı tahliyesi ve benzeri, çok katmanlı yapı, dolaşım ve tam arıtma ile, birçok kez arıtma etkisi sağlayabilir, iyi bir çevre koruma etkisi ve güçlü arıtma fonksiyonu vardır.

Bu makine, odun kömürü yakma sürecinde oluşan duman gazının artık doğrudan havaya salınmamasını sağlar, ancak duman gazı arıtma işlemi sonrası, yanıcı gaz haline getirilerek ikincil yanma için kullanılır. Ayrıca, odun katranı toplama, depolama ve satış dumanından ayrılır, böylece karbon dumanı emisyonlarını etkili şekilde durdurur ve çevre koruma ihtiyaçlarını karşılar.

Duman gazı arıtma1

Duman gazı arıtma2

Duman gazı arıtma3

Duman gazı arıtma 4

Duman gazı arıtma ekipmanı Ana özellikler:

- Duman gazı arıtma ekipmanı, kömür tozunu adsorbe edebilir ve tamamen arıtıp filtreleyebilir, katran, odun sirkesi sıvısı, karbon oksijen bileşiği ve metan hidroksit gibi, kömür üretim sürecinde üretilen ve etkili bir şekilde çevreye toksik gaz ve duman kirliliğini önleyen maddeler.

- Duman gazı arıtma ekipmanı, odun kömürü tesisini tek bir ‘karbon’ üretiminden, ‘karbon’, ‘gaz’ ve ‘yağ’ birleşik üretimine dönüştürebilir. Odun katranı biyodizel rafine edilmesi için önemli bir malzemedir ve odun sirke kimyasal bir malzemedir. Makine, odun kömürü tesisinin çok katmanlı faydalar elde etmesini sağlar, kömür ürünlerinin katma değerini daha da artırır.

- Ekipman büyük işlem kapasitesine sahip, basit kullanım, uzun servis ömrü ve manuel bakım gerektirmez.

Sıcak Ürün

Toz ve Pirinç Kabuğu Kurutmak için Sürekli Kurutucu

Endüstriyel testere tozu kurutucuları ve pirinç kabuğu kurutma makineleri…

Yatay Kömür Fırını Biyokömür Karbonizasyonu İçin

Yatay kömür fırını, yüksek verimli…

Kavak İşleme Makinesi

Sanayi tipi ahşap kereste makineleri kütükleri…

Kömür Kömürü Paketleme Makinesi ile Barbekü Kömürü Paketleme Makinesi

Bu kantitatif kömür kömürü paketleme makinesi, şu şekilde olabilir…

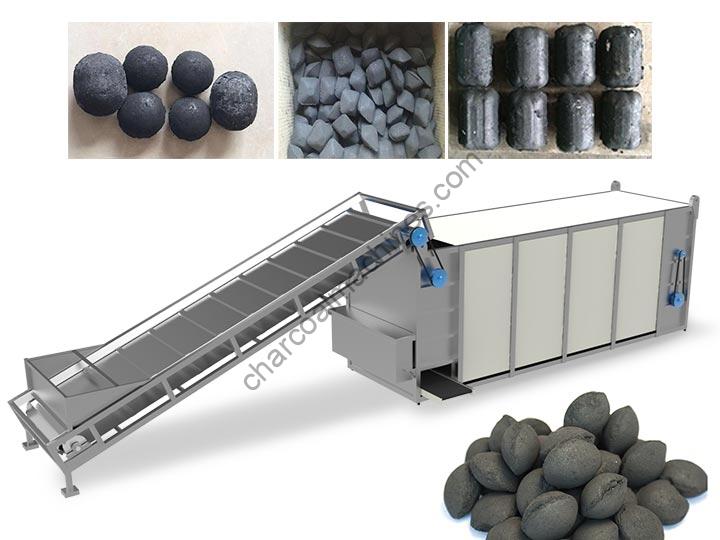

Yuvarlak ve Yastık Şekilli Barbekü Kömürü Pres Makinesi

Barbekü kömür pres makinesi, sıkıştırılmış kömür yapabilir…

Ağ Mesh Kurutucu ile Peletleri Sürekli Kurutma

Ağ bantlı kurutucu, bir parçasıdır…

Bal peteği Kömür Pelet Pres Makinesi

Hücreli kömür briket makinesi, öğütülmüş kömür tozunu sıkıştırabilir…

Palet Blokları Yapmak için Ahşap Palet Makinesi

Ticari odun palet blok makineleri,…

Biyokütle Ahşap Pelet Üretim Hattı

Biyomass odun pelet üretim hattı

Yorum Yok.