Μηχανή Άλεσης Ξύλινου Πούδρας για Παραγωγή Ξυλάνθρακα σε Πούδρα

Μηχανή παραγωγής ξύλινου αλεύρου | Μηχανή άλεσης ξύλινου αλεύρου

Μηχανή Άλεσης Ξύλινου Πούδρας για Παραγωγή Ξυλάνθρακα σε Πούδρα

Μηχανή παραγωγής ξύλινου αλεύρου | Μηχανή άλεσης ξύλινου αλεύρου

Η μηχανή ξύλινου αλεύρου (μηχανή άλεσης, μηχανή θραύσης) χρησιμοποιείται για το θρυμματισμό και το άλεσμα ελαφρών υλικών, ινωδών υλικών, εύθραυστων υλικών, ανθεκτικών υλικών και άλλων υλικών. Η λεπτότητα του ξύλινου αλεύρου που επεξεργάζεται αυτή η μηχανή μπορεί να φτάσει τα 800-1000 mesh, καλύπτοντας το κενό στην παραγωγή υπερελαφρού σκόνης στην αγορά. Ταυτόχρονα, μπορεί να διαχωριστεί σε δύο επίπεδα στη διαδικασία άλεσης. Ο εξοπλισμός διαθέτει λογικό σχεδιασμό, χαμηλή απώλεια, χαμηλό θόρυβο, χωρίς μόλυνση και εύκολη λειτουργία.

Εύρος εφαρμογής της μηχανής ξύλινου αλεύρου

Μπαμπού, φλούδα, κινεζική βοτανοθεραπεία, φλοιός, φύλλα, πίτουρο σιταριού, αλεσμένο ταραμά, μαύρη κάνναβη, φλούδα ρυζιού, καλαμπόκι, στέλεχος πορτοκαλιού, άμυλο, τρόφιμα, δέρμα γαρίδας, ιχθυάλευρο, φύκια, αποξηραμένα λαχανικά, hawthorn, αποξηραμένη τζίντζερ, σκόνη σκόρδου, κολοκυθόσπορος, καρυκεύματα, χουρμάδες, χαρτί, πλακέτες κυκλώματος, πλαστικά, χημικά υλικά, θαλάσσια προϊόντα, μίκας, γραφίτης, βεντονίτης, περλίτης, αποστακτήρια, φλούδα, τάρτα, ενεργός άνθρακας, κυτταρίνη, κατάλοιπα πατάτας, τσάι, τρίχες, σόγια, βαμβάκι, δέρμα βοοειδών, δέρμα προβάτων, ρίζες φυτών, στελέχη, φύλλα, λουλούδια, φρούτα και διάφορα βρώσιμα μανιτάρια μπορούν να επεξεργαστούν σε λεπτά σκόνη με αυτήν τη μηχανή.

Η μηχανή ξυλόσκαφης χρησιμοποιείται ευρέως σε χημικά, δομικά υλικά, φαρμακευτικά, υγεία, κτηνοτροφία, τροφίμων και άλλες βιομηχανίες.

Μηχανή αλέσματος ξυλοπλάστης βίντεο

Η κύρια δομή του ξύλου σκόνη μηχάνημα

- Η λεπίδα θρυμματισμού αποτελείται από λεπίδα τύπου 7, λεπίδα τύπου 1 και μια περιστροφική λεπίδα.

- Η συνημμένη μηχανή αποτελείται από έναν ανεμιστήρα, έναν συλλέκτη σκόνης και έναν συλλέκτη σκόνης.

- Ο κύριος θάλαμος θρυμματισμού υιοθετεί ένα τύπο λεπίδας 7, ένα τύπο λεπίδας 1 και μια περιστροφική λεπίδα.

- Υπάρχουν χονδρή θραύση, λεπτή θραύση και περιστροφική σύνθετη θραύση.

Λειτουργία της ξυλοπλάστης μηχάνημα

- Αυτή η μηχανή χρησιμοποιεί τον κινητήρα για να κινήσει το ρότορας του θαλάμου θραύσης ώστε να λειτουργεί με υψηλή ταχύτητα, ώστε η μηχανή να παράγει ρεύμα υψηλής ταχύτητας για να δημιουργήσει δυνάμεις υψηλής έντασης, συμπίεσης, κοπής και τριβής στο θρυμματισμένο υλικό για να επιτύχει τη μοναδική λειτουργία άλεσης.

- Κατά τη διάρκεια της κοπής και θραύσης των τριών λεπίδων, ο ρότορας παράγει έναν υψηλής ταχύτητας ρεύμα αέρα που περιστρέφεται στην κατεύθυνση της λεπίδας. Το υλικό επιταχύνεται στον ρεύμα αέρα και επανειλημμένα συγκρούεται και κόβεται με τριβή. Ταυτόχρονα, υφίσταται τρεις τύπους θραύσης.

- Το θρυμματισμένο υλικό εισέρχεται στον αναλυτή με τον αέρα. Για ανάλυση, λόγω της φυγόκεντρης δύναμης του ρότορα του αναλυτή και της φυγόκεντρης δύναμης του ρεύματος αέρα, όταν η φυγόκεντρη δύναμη είναι μεγαλύτερη από τη κεντρομόλο, τα λεπτά σωματίδια εισέρχονται στον συλλέκτη με τον αέρα, και τα χοντρά σωματίδια εισέρχονται στον κυκλικό ανασυνδυασμό θάλαμο και συνεχίζουν να θρυμματίζονται μέχρι να επιτευχθεί η επιθυμητή λεπτότητα.

Αποτέλεσμα άλεσης αλεύρου ξύλου

Μέθοδος ρύθμισης της λεπτότητας του ξύλου σκόνη μηχανή λείανσης

- Η λεπτότητα της μηχανής ξύλινου αλεύρου μπορεί να ρυθμιστεί αυθαίρετα μεταξύ 30–350 mesh. Η απόδοση και η λεπτότητα μπορούν να ρυθμιστούν αυτόματα σύμφωνα με τη συγκεκριμένη βαρύτητα του υλικού. Ο κύριος κινητήρας της μηχανής καθορίζεται ανάλογα με το θρυμματισμένο υλικό.

- Το βοηθητικό μηχάνημα της μηχανής άλεσης ξύλου είναι εξοπλισμένο με ρυθμιστή όγκου αέρα, ο οποίος μπορεί να ρυθμίσει τον όγκο του αέρα. Όσο μεγαλύτερος ο όγκος του αέρα, τόσο χαμηλότερη η λεπτότητα, και το αντίστροφο. Συνεχής παραγωγή όταν ρυθμίζεται στη ζητούμενη λεπτότητα.

- Υπάρχει αναλυτής λεπτότητας στον διαχωριστή της μηχανής άλεσης ξύλου. Με χαλάρωση του βίδας στον αναλυτή, αυξάνεται η λεπτότητα της ανόδου και μειώνεται η λεπτότητα της καθόδου. Μετά την ρύθμιση στη ζητούμενη λεπτότητα, η σταθερή βίδα μπορεί να παραχθεί.

Θερμό Προϊόν

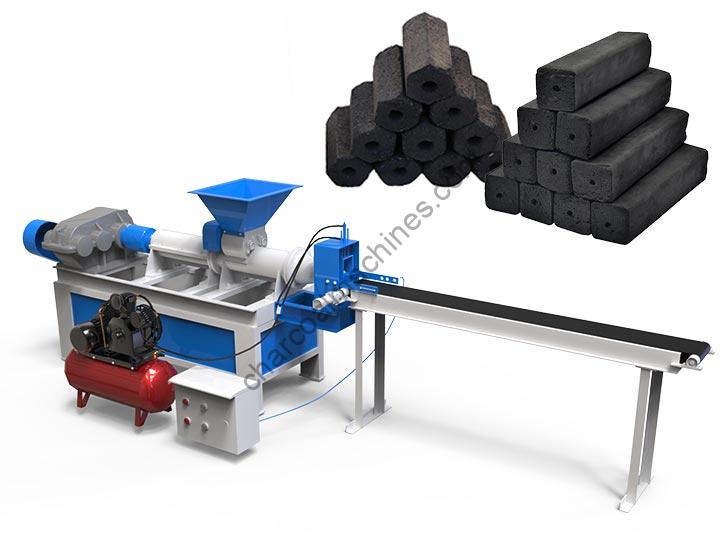

Εξωθητής Μπρικέτας Ξυλάνθρακα για Εργοστάσιο Ξυλάνθρακα

Ο μηχανισμός συμπίεσης κάρβουνου μπορεί να εκθλίψει κάρβουνο & άνθρακα…

Μηχανή Παραγωγής Ξυλάνθρακα: Ο Απόλυτος Οδηγός για Υψηλής Απόδοσης Παραγωγή Βιοκαρβουνου

Ο νεότερος μηχανισμός κατασκευής άνθρακα είναι ο ιδανικός…

Κονιορτοποιητής Ξυλάνθρακα | Μηχανή Κοσκίνισης Πούδρας Ξυλάνθρακα

Ο θρυμματιστής κάρβουνου μπορεί κυρίως να θρυμματίσει διάφορα…

Μηχανή Πίεσης Μπάλας Ξυλάνθρακα για Κυκλική & Μαξιλαροειδή Μπάλες Ξυλάνθρακα

Μηχανήματα συμπίεσης μπρικέτας BBQ ξυλάνθρακα μπορούν να κατασκευάσουν συμπιεσμένο ξυλάνθρακα…

Υψηλής Αποδοτικότητας Μηχανή Παραγωγής Μπρικέτας Σαπισμένων Ξύλων

Η βιομηχανική μηχανή συμπίεσης ξύλινων σκόνης χρησιμοποιείται κυρίως για…

Γραμμή Παραγωγής Συμπιεσμένων Ξύλινων Πλακών

Η γραμμή παραγωγής συμπιεσμένων ξύλινων παλετών είναι μια…

Μηχανή Συσκευασίας Ξυλάνθρακα για Ποσοτική Συσκευασία Μπάρμπεκιου Ξυλάνθρακα

Αυτή η ποσοτική μηχανή συσκευασίας ανθρακούχων μπρικέτας μπορεί να είναι…

Μηχανή Παραγωγής Συμπιεσμένων Ξύλινων Παλετών για Μορφωμένες Παλέτες

Η μηχανή συμπίεσης ξύλινων παλετών μπορεί να κάνει συμπιεσμένο κάρβουνο…

Γραμμή Παραγωγής Βιομάζας Ξύλινων Σφαιριδίων

Η γραμμή παραγωγής pellet ξύλου βιομάζας είναι μια…

2 σχόλια