The difference between coconut shell charcoal and powdered activated carbon

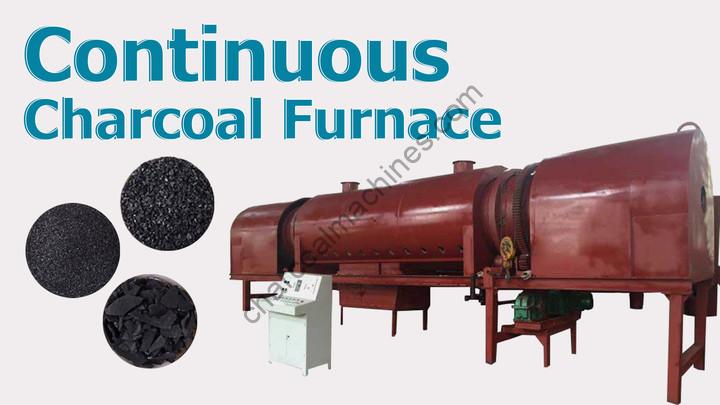

Wood powdered activated carbon and coconut shell charcoal are two types of activated carbon that are often used in daily life. Both have the characteristics of relatively large areas and developed void structures. What is the difference between these two types of carbon? Coconut shell charcoal is usually made by a 連続炭化炉, and activated carbon is only after activation treatment.

Appearance difference

The fineness of powdered activated carbon is usually 100 mesh, 150 mesh, 200 mesh, 325 mesh. And it is a fine powder.

The coconut shell charcoal usually has a fineness of 4-8 mesh, 5-10 mesh, 6-12 mesh, 8-16 mesh, 8-30, 10-24 mesh, 20-40, mesh, 30-60 mesh, 40 Irregular granular shape of -60 mesh and 60-80 mesh.

Lodine value

The iodine value of wood powdered activated carbon can reach up to 800 iodine. The iodine value of coconut shell charcoal can reach 1200 iodine. The iodine value of charcoal represents the adsorption capacity of its activated carbon. The higher the iodine value, the more expensive the activated carbon.

Applications

The main use of wood powdered activated carbon is water purification and decolorization in the food, beverage, printing, and dyeing industries. This activated carbon can also be added with a binder and processed into a filter element used in water treatment equipment or a filter screen in air purification equipment.

The main purpose of coconut shell charcoal is as a carrier for gold extraction and solvent recovery. In addition, because of its strong adsorption, coconut shell charcoal can also be used as a gas mask, cigarette filter, refrigerator deodorant, and automobile exhaust gas treatment device.

Coconut shell charcoal is used for liquid-phase adsorption and can be used for the dechlorination of drinking water. Coconut shell charcoal has relatively many uses, while the use of wood powdered activated carbon is more targeted.

How is coconut shell charcoal produced?

At present, most of the coconut shell charcoal on the market is processed by carbonization equipment. The most efficient equipment for producing coconut shell charcoal is the 連続炭化炉, which can produce up to 2t/h per hour. The continuous carbonization furnace is a rotating drum structure, which can realize the continuous production of coconut shell charcoal.

コメントはありません。