Dik Dikey Karbonizasyon Fırını Sert Ahşap Kömürü Üretimi İçin

Hava akışlı Kömür Fırını | Odun Kömürü Yapma Makinesi

Dik Dikey Karbonizasyon Fırını Sert Ahşap Kömürü Üretimi İçin

Hava akışlı Kömür Fırını | Odun Kömürü Yapma Makinesi

Özellikler Hızlı Bakış

Dikey karbonizasyon fırını, hava akışlı kaldırma karbonizasyonu makinesi olarak da adlandırılır, gelişmiş gaz akışlı karbonizasyon teknolojisini kullanarak her türlü biyokarbonu üretir. Bu kömür makinesi fırını, daha az arazi kullanımı, basit ve kullanışlı operasyon, güvenlik ve çevre koruma ile yüksek üretim verimliliği avantajlarıyla karbonizasyon oranını büyük ölçüde artırabilir. Bu toplu karbonizasyon makinesi, sert odun kömürü, bambu kömürü, saman kömürü, kabuk kömürü, hindistan cevizi kabuğu kömürü vb. yapmada yaygın olarak kullanılır.

Dikey karbonizasyon fırını, kaldırma kombinasyon yapısı kullanır, kaldırma soğutma yöntemiyle çalışır, bir gün içinde birden fazla fırın karbonize edilebilir, üretim süresi büyük ölçüde kısalır, kömür üretim verimliliği artırılır, büyük ve orta ölçekli kömür üreticileri için idealdir.

Kaldırma tipi karbonizasyon fırını fabrika gösterimi

Dikey karbonizasyon fırını ile karbonizasyon için hammadde

Dikey karbonizasyon fırını, odun, kütük, odun parçaları, sert odun, çam, palmiye odunu, hindistan cevizi kabuğu, palmiye kabuğu, bambu, kabuk, saman sapı, odun parçaları, mobilya artıkları, talaş briketleri vb. çeşitli biyokütle hammaddelerini doğrudan karbonize edebilir.

Kaba istatistiklere göre, müşterilerin yüzde 80’i bu düşey karbonizasyon ekipmanını bambu, ağaç dalları, parçacıklar halinde kesilmiş ağaç, sağlam hindistancevizi kabukları gibi büyük boyutlu hammaddeyi karbonize etmek için satın alır.

Bu biyokarbon makinesi, Afrika ve Güneydoğu Asya pazarlarında her zaman çok popüler olmuştur. Bunun nedeni, bazı müşterilerin karbonizasyon konusunda yüksek gereksinimleri olmaması, sadece büyük miktarda biyomass atığını geri kazanmak ve karbon haline getirmek istemeleridir. Daha sonra, bitmiş kömür doğrudan yerel pazarda satılabilir veya toplu olarak diğer ülkelere ihraç edilebilir.

Kaldırma karbonizasyon fırını yapısı

Sürekli karbonizasyon fırını yapısında tek parça yapısından farklı olarak, bu karbonizasyon ekipmanının yapısı çoklu parçalardan oluşur.

Kaldırma karbonizasyon fırınının yapısı, ana olarak dört bölümden oluşur: kaldırma cihazı, iç fırın, dış fırın ve gaz dolaşım hattı.

Karbonsuzlaştırma fırını, karbonizasyon sırasında oluşan duman gazını tam olarak kullanmak için benzersiz bir duman gazı arıtma sistemine sahiptir.

Fırının kendi kullanımının yanı sıra, enerji tasarrufu ve çevre koruma gereksinimlerini de karşılar. Kalan ` duman gazı, kurutma, karbonizasyon ve ısı kaynağı olarak kullanılabilir, üretimde büyük yakıt tasarrufu sağlar ve işletme avantajlarını artırır.

Dış Fırın

Kaldırma karbonizasyon fırının dış fırını, kalın çelik levhalar ve refrakter tuğlalardan oluşur.

Dış fırının yüzeyi, varil şeklinde çelik levhadan yapılmıştır, iç duvarı bir tabaka refrakter tuğla ile kaplıdır ve refrakter tuğla boşlukları genellikle özel refrakter yapıştırıcı ile doldurulur.

Dış fırının alt kısmı, hava delikleri olan spiral borulardan oluşan bir yanma odasıdır.

İç fırın

Dikey karbonizasyon fırını iç fırını, yüklenip boşaltılabilen, çelik levhadan yapılmış bir iç kısımdır.

İç fırın, karbonizasyon yapılacak hammaddeleri tutmak için kullanılır, örneğin ağaç dalları, talaş briketleri vb. Genellikle, bir karbonizasyon fırını üç standart iç tank ile donatılmıştır ve çalışma sırasında sırayla kullanılabilirler.

Yükleme kutusu

Hammaddeyi doğrudan iç fırına eklemenin yanı sıra, doldurma işlemini kolaylaştırmak için yükleme kutusu da kullanılabilir. Pratik uygulamalarda, bu yükleme kutusu düzenli şekilli talaş briketlerinin karbonizasyonunda sıklıkla kullanılır.

Kaldırma vinci

Kaldırma karbonizasyon fırını kullanırken, otomatik olarak iç fırını kaldırabilen bir kaldırma vinci donatmak gerekebilir, bu hem üretim verimliliğini artırır hem de işgücü tasarrufu sağlar. Bu kaldırma cihazı uzaktan kumanda ile kontrol edilebilir, iç fırını yükleme ve boşaltma işlemleri yapılabilir.

Duman gazı arıtma sistemi

Duman gazı arıtma sistemi, kaldırma kömür fırını için opsiyonel bir cihazdır, karbonizasyon sürecinde oluşan egzoz gazını filtrelemek ve yanıcı gazı geri kazanmak için kullanılır.

Duman gazı arıtma cihazlarımız, geleneksel filtreler ve elektrostatik duman gazı arıtma cihazları olarak ikiye ayrılır.

Kaldırma karbonizasyon fırını videosu

Dikey Karbonizasyon Fırını Özellikleri

Bu enerji tasarruflu ekipman, kullanımı kolaydır, güç ve elektrik olmadan taşınabilir üretim yapabilir, büyük ölçekli kömür üretimi için idealdir.

Üretim ihtiyaçlarına göre, hava akışlı kaldırma kömür fırını tek silindirli, üç silindirli, dört silindirli ve diğer çok tanklı silindir formlarına ayarlanabilir, farklı müşterilerin kömür çıkış ihtiyaçlarını karşılamak için.

Özellikler bu Dikey karbonizasyon fırını

- Enerji tasarrufu ve hijyen. Çünkü sert odun kömürü fırını, sıcak gaz akışının dengeli dolaşım karbonizasyonu tasarımını benimser, duman ve tozun geri kazanımını ve kullanımını gerçekleştirir, tutuşturma odunu tüketimini büyük ölçüde tasarruf eder ve artan duman gazı Ayrıca kurutma, ısıtma ve diğer üretim süreçlerinde de kullanılabilir, diğer karbonizasyon yöntemlerinin çözemediği duman ve toz kirliliği, yüksek malzeme tüketimi gibi eksiklikleri etkili bir şekilde geliştirmiştir.

- Sürekli ve birleşik üretim gerçekleştirilebilir, kömür çıkışını artırmak için. En son döngü karbonizasyon tasarımını benimseyerek, karbonizasyon döngüsü büyük ölçüde kısaltılmıştır. Önceki 72 saat olan karbonizasyon süresi şu anda 8-16 saate indirilmiş ve sürekli ardışık üretim sağlanabilir, bu da kömürün standartlaştırılması ve büyük ölçekli üretimi için koşullar yaratır ve küçük ölçekli, dağınık ve karmaşık üretim sorunlarını çözer.

- Kömürleşme verimi yüzde 99’a kadar çıkabilir ve kömürleşmiş karbon içeriği ile görünüm kalitesi önemli ölçüde iyileştirilmiştir. Karbonizasyon sürecinde her yerden gelen hava akışının kullanılması, her yerde mevcut denge avantajları, karbonizasyon döngüsünü büyük ölçüde kısaltmış ve kömürleştirme kalitesi, görünümü ve verimi farklı derecelerde iyileştirilmiştir.

- Gelirinizi artırın. Hava akışlı kaldırma karbonizasyon fırını, müşterinin talebine göre odun yağı ve odun sirvesi gibi pahalı yan ürünleri geri kazanabilir, çevre kirliliğini azaltır ve karbon üretim verimliliğini artırır.

- Kullanımı kolay, öğrenmesi kolay teknoloji. Bu odun kömürü fırını, diğer karbonizasyon fırını türlerinin gerekli fanlar, motorlar ve diğer karmaşık cihazlarını ortadan kaldırır. Elektrik üretimi olmadan çalışır, işçilik ve teknik yoğunluğu azaltır, güvenli ve basit operasyon sağlar, çalışanlar kısa sürede kullanmayı öğrenebilir.

Biyokarbonun teknik parametreleri makine

| Model | SL-C1500 |

| Çıkış kapasitesi | 2.5T-3T/24 saat (Verim, farklı hammaddelere göre değişir) |

| Bir seferlik karbonizasyon süresi | 6-8 saat (farklı hammaddelere ve yükleme miktarına göre değişir) |

| Çelik kalınlığı | Yaklaşık 6mm, özelleştirilebilir |

| İç fırın boyutu | 1.5m*1.5m |

| Parçaları içerir | bir fırının standart konfigürasyonu 3 iç fırındır |

| Makine ağırlığı | 2.8 ton |

| Boyut | 1940*1900*1900mm |

| Enerji tüketimi | 8 saat içinde 50-80kg biyokütle atığı |

Kaldırma Karbürizasyon fırını çalışma videosu

Shuliy fabrikasında kömür karbonizasyon fırını gösterimi

Biyokarbon makinesi müşteri örnekleri

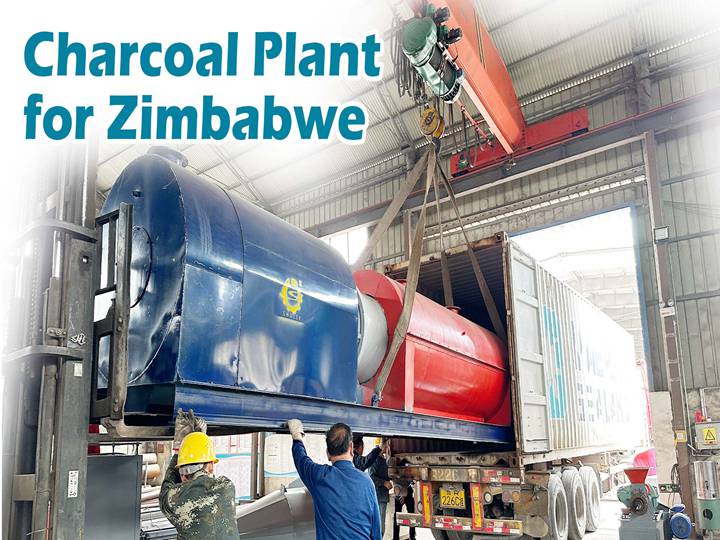

Shuliy Fabrikası, 10 yıldan fazla süredir karbonizasyon fırınları üretmekte ve ihraç etmektedir. Çeşitli karbonizasyon ekipmanlarımız, 50'den fazla ülke ve bölgeye ihraç edilmiştir.

Müşterilere yüksek kaliteli ekipman ve zamanında teslimat sağlamanın yanı sıra, müşteri ihtiyaçlarına göre ekipman montajı ve işletme rehberliği sağlamak üzere mühendisler de sevk edilebilir.

Sıcak Ürün

Ev Kullanımı için Diskli Ahşap Parçalama Makinesi

Küçük diskli ahşap kırıcı, kütükleri… işleyebilir

Kömür ve Kömür Tozu Kırıcı | Kömür Tozu Öğütücü Makinesi

Kömür kırıcı makinesi, çeşitli…

Kavak İşleme Makinesi

Sanayi tipi ahşap kereste makineleri kütükleri…

Biyokömür Yapımı için Kömür Makinesi ve Üretim Hattı

Kömür yapma makineleri, biyokütle atıklarını…

Duman Gazı Arıtma Ekipmanları

Duman gazı arıtımı Geçmişte, çünkü…

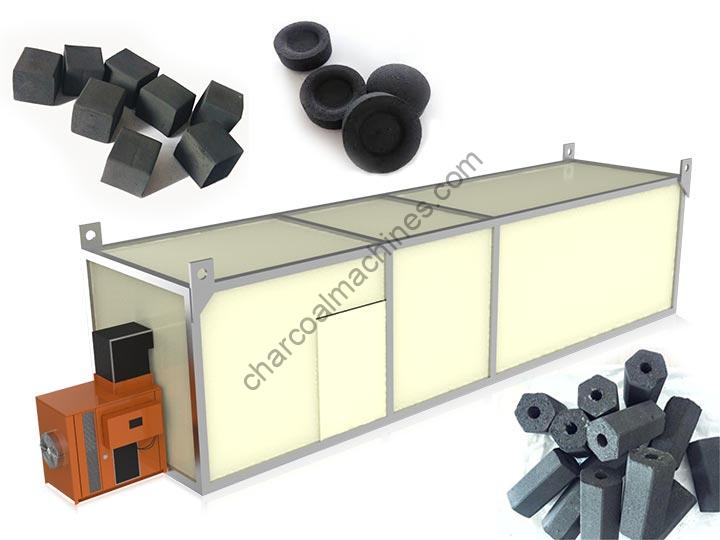

İyi Performanslı Parti Kömür Kurutma Makinesi

Kömür kurutucu makinesi esasen kullanılır…

İnce Kömür Tozu Öğütmek için Raymond Makinesi

Raymond değirmeni esas olarak bir parça olarak kullanılır…

Hookah Shisha Kömürü Üretim Hattı | Yuvarlak ve Küp Peletler Yapımı

Şişe nargile kömürü üretim hattı tasarlanmıştır…

Kömür Kömürü Paketleme Makinesi ile Barbekü Kömürü Paketleme Makinesi

Bu kantitatif kömür kömürü paketleme makinesi, şu şekilde olabilir…

8 yorum