लकड़ी पैलेट ब्लॉक मशीन पैलेट ब्लॉक बनाने के लिए

लकड़ी पैलेट ब्लॉक बनाने वाली मशीन | सैंडस्ट ब्लॉक मशीन

लकड़ी पैलेट ब्लॉक मशीन पैलेट ब्लॉक बनाने के लिए

लकड़ी पैलेट ब्लॉक बनाने वाली मशीन | सैंडस्ट ब्लॉक मशीन

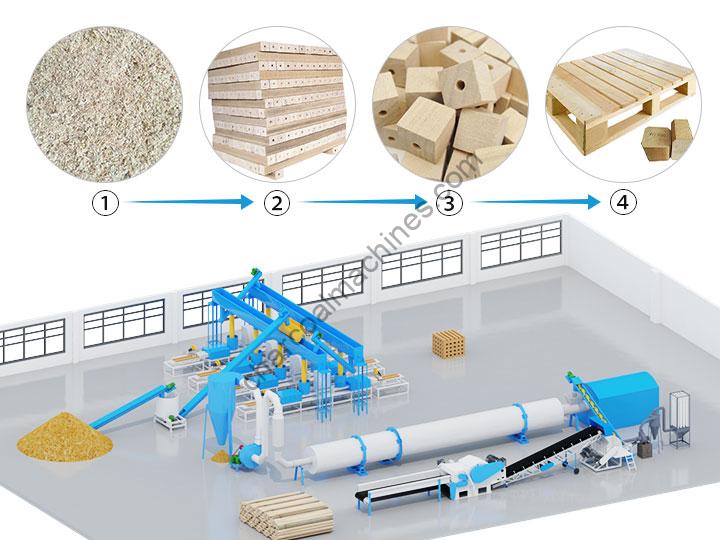

वाणिज्यिक लकड़ी पैलेट ब्लॉक बनाने वाली मशीनें बायोमास कच्चे माल जैसे सैंडस्ट और लकड़ी के झरने को उच्च तापमान और उच्च दबाव की स्थिति में ठोस ब्लॉक में एक्सट्रूड कर सकती हैं। तैयार लकड़ी के ब्लॉक को काटकर लकड़ी के पैलेट के पैर बनाए जा सकते हैं। सैंडस्ट ब्लॉक मशीन का उपयोग कर लकड़ी के पैलेट ब्लॉक बनाने की प्रक्रिया मुख्य रूप से सैंडस्ट सुखाने, सैंडस्ट ब्लॉक एक्सट्रूडिंग, संकुचित ब्लॉक काटने आदि में शामिल है। लकड़ी के ब्लॉक का आकार और लंबाई ग्राहक की आवश्यकताओं के अनुसार अनुकूलित की जा सकती है।

संकुचित लकड़ी के पैलेट ब्लॉक बनाने के लिए कच्चा माल

प्रक्रिया के लिए कई प्रकार के कच्चे माल होते हैं, और लगभग सभी बायोमास चिप्स का उपयोग उत्पादन के लिए किया जा सकता है। सबसे सामान्य कच्चे माल सैंडस्ट और लकड़ी के झरने, नारियल फाइबर, भूसी के टुकड़े आदि हैं।

कच्चे माल के लिए आवश्यक मुख्य विशेषताएँ

मटेरियल साइज: 5 मिमी से कम। हम सभी प्रकार के बायोमास वेस्ट को चीरने के लिए लकड़ी श्रेडर का उपयोग कर सकते हैं, जैसे शाखाएं, लकड़ी के टुकड़े, पेड़ की जड़ें, लॉग, वेस्टवुड बोर्ड आदि, जिन्हें 3-5 मिमी के साइज में सैंडस्ट और लकड़ी के झरने में बदला जा सकता है।

सामग्री आर्द्रता: 10% से कम। सैंडस्ट और लकड़ी के झरने जैसे कच्चे माल की आर्द्रता 10% से अधिक नहीं होनी चाहिए। यदि कच्चे माल की आर्द्रता बहुत अधिक है, तो तैयार उत्पाद की गुणवत्ता खराब होगी, और प्रसंस्करण दक्षता बहुत कम हो जाएगी। हम निरंतर सुखाने के लिए सैंडस्ट ड्रायर का उपयोग कर सकते हैं और कच्चे माल की नमी को जल्दी से कम कर सकते हैं।

लकड़ी पैलेट ब्लॉक मशीन बिक्री के लिए

लकड़ी पैलेट ब्लॉक बनाने वाली मशीन में एक सेट बाएं और दाएं सममित एक्सट्रूज़न डिवाइस होते हैं। मशीन की मुख्य संरचना में फीडिंग पोर्ट, फ्रेम, हीटिंग प्लेट, हाइड्रोलिक सिलेंडर, एक्सट्रूज़न डाई आदि शामिल हैं।

जब सैंडस्ट पैलेट ब्लॉक मशीन काम कर रही होती है, तो इसकी आंतरिक हाइड्रोलिक डिवाइस फीडिंग पोर्ट से प्रवेश करने वाले सैंडस्ट को आगे बढ़ाने के लिए धकेलती है। जब सैंडस्ट को मशीन के हीटिंग क्षेत्र में धकेला जाता है, तो सैंडस्ट और अन्य बायोमास फीडस्टॉक्स में लिग्निन थर्मली टूट जाता है और पूरी तरह से फीडस्टॉक के अणुओं से बंध जाता है।

इसलिए, लकड़ी पैलेट ब्लॉक मशीन से संसाधित सैंडस्ट ब्लॉक आमतौर पर चिकनी सतह, उच्च घनत्व और कठोरता, बहुत पहनने के प्रतिरोधी और मजबूत लोड-बेयरिंग क्षमता रखते हैं।

सैंडस्ट ब्लॉक मशीन कैसे काम करती है?

लकड़ी ब्लॉक बनाने के लिए गोंद क्यों मिलाया जाता है?

लकड़ी के पैलेट ब्लॉक बनाने से पहले, हम आमतौर पर सैंडस्ट को मिक्सर में डालते हैं और उसमें एक निश्चित अनुपात में गोंद मिलाते हैं, ऐसा क्यों? वास्तव में, इस मिलाए गए गोंद को यूरिया-फॉर्मल्डिहाइड रेजिन गोंद कहा जाता है, जो एक सुरक्षित और गैर-टॉक्सिक थर्मोसैटिंग पॉलिमर चिपकने वाला है।

गोंद फॉर्मलडिहाइड, यूरिया, पॉलीविनाइल अल्कोहल, मेलामाइन, अमोनिया, और पीएच समायोजक के लिए क्षार और अम्ल से बना होता है। गोंद मिलाने का उद्देश्य सैंडस्ट के बीच चिपकने की दृढ़ता बढ़ाना है, ताकि संसाधित लकड़ी के ब्लॉक बेहतर घनत्व और कठोरता प्राप्त करें।

लकड़ी पैलेट ब्लॉक बनाने वाली मशीन के पैरामीटर्स

| मॉडल | Power | Capacity | आयाम | वजन |

| SL-75/2 | 15KW | 3.5m³/दिन | 75*75*1200मिमी | 1500किग्रा |

| SL-90/2 | 15KW | 4m³/दिन | 90*90*1200मिमी | 1800किग्रा |

| SL-100/2 | 18KW | 5m³/दिन | 100*100*1200मिमी | 2000किग्रा |

| SL-120 | 15KW | 3.5m³/दिन | 100*120*1200मिमी | 1500किग्रा |

| SL-145 | 18KW | 3.5m³/दिन | 145*145*1200मिमी | 1800किग्रा |

हॉट प्रोडक्ट

छोटा फीड पेलेट मशीन जानवरों के भोजन बनाने के लिए

छोटा फीड पेलट मशीन घर पर…

सतत ड्रायर सॉडस्ट और चावल भूसी सुखाने के लिए

औद्योगिक सॉडस्ट सुखाने वाली मशीनें और चावल भूसी सुखाने वाली मशीनें…

हनीकॉम्ब कोयला ब्रिक्वेट प्रेस मशीन

मधुमक्खी कोयला ब्रीकेट मशीन पाउडर को दबा सकती है…

ब्रिक्वेट कटर ब्रिक्वेट चारcoal बनाने के लिए आवश्यकतानुसार

कोयला ब्रीकेट काटने वाली मशीन का उपयोग…

थर्मल श्रिंक पैकिंग मशीन सॉडस्ट पिनी के ब्रिक्वेट्स पैकिंग के लिए

यह स्वचालित थर्मल संकुचन पैकिंग मशीन हो सकती है…

लकड़ी पाउडर ग्राइंडर मशीन लकड़ी का आटा बनाने के लिए

लकड़ी का पाउडर मशीन का उपयोग…

रेमंड मिल महीन चारcoal पाउडर पीसने के लिए

रेमंड मिल मुख्य रूप से एक टुकड़ा के रूप में उपयोग किया जाता है…

लकड़ी डिबार्कर मशीन लॉग छीलने के लिए

लकड़ी का डिब्बा मशीन, जिसे लॉग भी कहा जाता है…

संपीड़ित लकड़ी का पैलेट उत्पादन लाइन

दबाव लकड़ी के पैलेट उत्पादन लाइन एक…

2 टिप्पणियाँ