シュリイ炭化器がアメリカの木工工場のバイオマス廃棄物リサイクルを支援

中国のバイオマス圧縮および炭化装置の主要メーカーであるシュリイ機械は、最近、アメリカの木工工場に2台の炭化器を出荷しました。その工場はワシントン州に位置し、木材、家具、床材などさまざまな木製品を生産しています。この工場は、木屑、木片、樹皮などの大量のバイオマス廃棄物を生成しています。

アメリカのお客様のニーズは何ですか?

米国の顧客は、木材加工施設の所有者であり、バイオマス廃棄物をリサイクルし、追加収益を生み出す革新的なソリューションを求めていました。

彼らは、堆肥化、焼却、嫌気性消化などいくつかの選択肢を検討しましたが、最終的には炭化が彼らのニーズに最も適していると判断しました。

なぜ炭ビジネスを選ぶのか?

シュリイの木屑圧縮機と炭化器の導入は、木材廃棄物の再利用という顧客のビジョンと一致しています。これらの機械を利用して、残留木片や端材を価値のある炭製品に変換し、廃棄物を削減し、より環境に優しい環境に貢献しようとしています。

お客様向けのソリューション

シュリイ機械の炭化器は、バイオマス廃棄物を炭に変換するよう設計されています。これらの機械は効率的で操作も簡単であり、高品質の炭を生産します。アメリカの顧客に出荷された2台の炭化器は、1日あたり合計2,100キログラムの炭を生産できます。

木屑圧縮機は、300kg/hの生産能力を持ち、木材廃棄物を効率的に圧縮してブリケットにし、利用可能な資源を最大限に活用します。一方、垂直型炭化器は、バイオマスを炭に変換するための信頼性が高く高容量のソリューションを提供します。

注文に対する包括的なサポート

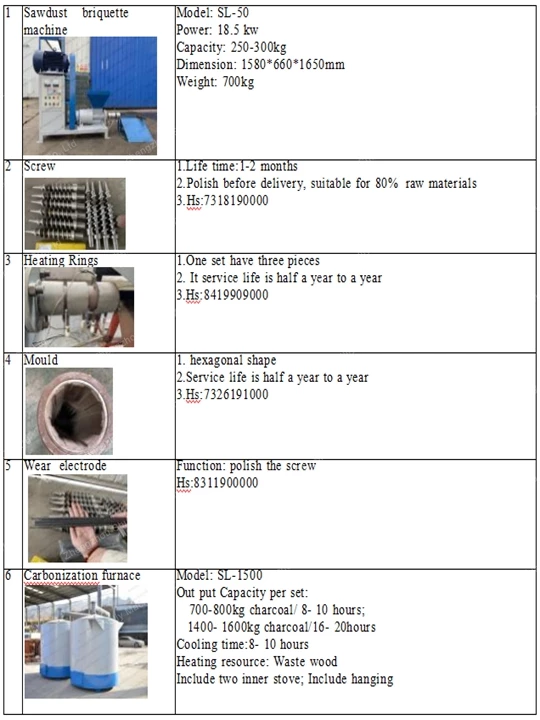

シームレスな運用を確保するために、米国の顧客はネジ、ヒーティングエレメント、六角型の金型などさまざまなアクセサリーも追加で注文しました。この包括的なアプローチは、シュリイ工場が機械と必要な部品を含む総合的なソリューションを提供することに対する献身を示しています。

アメリカのお客様へのメリット

アメリカの顧客は、シュリイの炭化器の性能に満足しています。これらの機械は、工場の廃棄物処理コストを削減し、炭の販売から追加収益を生み出すのに役立ちました。工場は今や、バイオマス廃棄物を調理、暖房、その他の用途に使える価値ある製品に変えることができます。

炭化機に関するお客様のフィードバック

「シュリイの炭化器に非常に満足しています」と工場長は述べました。「これらの機械は使いやすく、高品質の炭を生産します。廃棄物処理コストの削減と追加収益の生成に役立っています。」

シュリイ炭化機の主要な特徴

- 高効率:これらの機械は、バイオマス廃棄物の最大90%を炭に変換できます。

- メンテナンスが少なくて済む:長期運用を念頭に設計されており、最小限のメンテナンスで運用可能です。

- 幅広い用途:これらの機械は、木屑、木片、樹皮などさまざまなバイオマス材料を炭化させるために使用できます。

コメントなし