Kontinuerlig kolsugn för biomassa kolproduktion

Continuous Carbonization Furnace | Charcoal Carbonizing Kiln

Kontinuerlig kolsugn för biomassa kolproduktion

Continuous Carbonization Furnace | Charcoal Carbonizing Kiln

Vipengele kwa Muhtasari

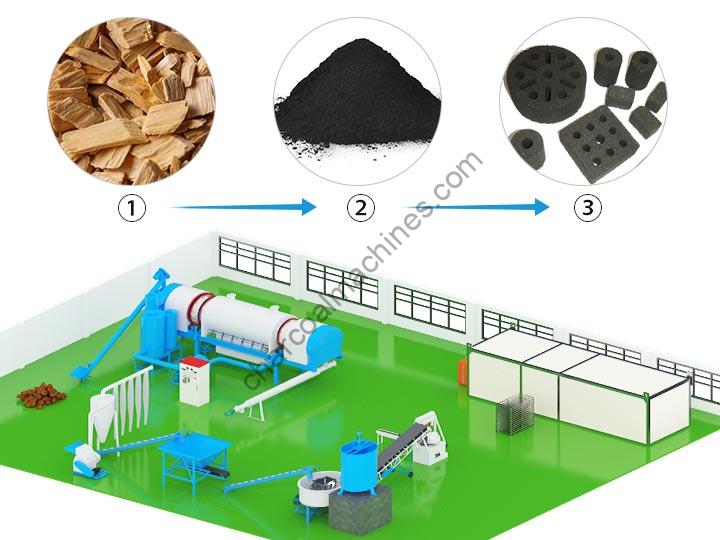

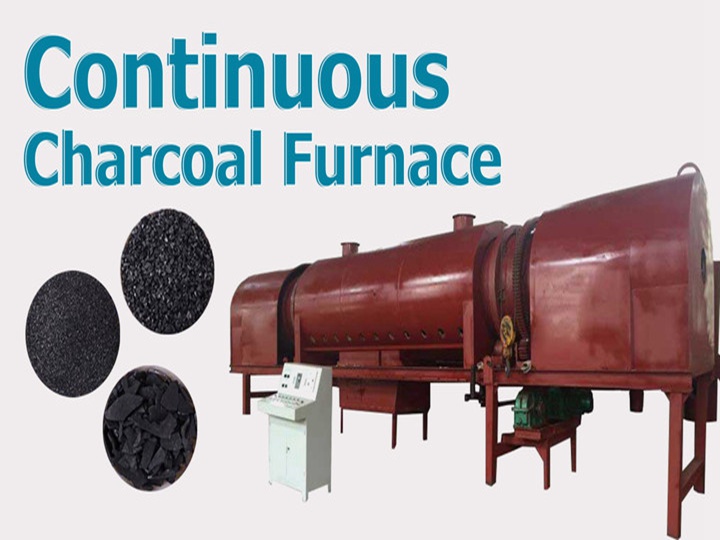

The continuous carbonization furnace is a new type of charcoal machine equipment. It is used for the mass production of rice husk charcoal and coconut shell charcoal. This industrial charcoal carbonizing furnace kiln is the upgrade of the traditional earth charcoal kiln in many Africa areas.

This continuous carbonization furnace can directly carbonize straw chips, rice husks, wood chips, sawdust, coconut shells, palm kernel shells, bamboo scraps, and other biomass materials. It has a difference from the hoist-type carbonization furnace and horizontal charcoal furnace.

With wide applications, it can also carbonize all kinds of wastes, such as paper mill wastes, wood factory wastes, plastic wastes, medical wastes, and municipal solid wastes.

This rotary coconut husk charcoal making machine is very popular among many African countries, Middle East, and Southeast Asian countries, such as Nigeria, Ghana, South Africa, Cameroon, Egypt, Guinea, Morocco, Sudan, Uganda, Saudi Arabia, Iraq, Jordan, Lebanon, Oman, Yemen, UAE, Philippines, Indonesia, Thailand, Malaysia, Cambodia, etc.

This continuous charcoal furnace is necessary equipment for various specifications of charcoal briquettes production lines and large-scale charcoal processing plants, such as hookah charcoal production lines, barbecue charcoal production lines, honeycomb coal production lines, etc. Charcoal carbonized by continuous carbonization furnace is also key equipment for industrial metallurgy, chemical, and pharmaceutical, soil improvement, deodorization operations, waste treatment, water purification, and household harmful gas removal.

Muundo wa tanuru ya kuoka makaa ya mkaa ya kuendelea

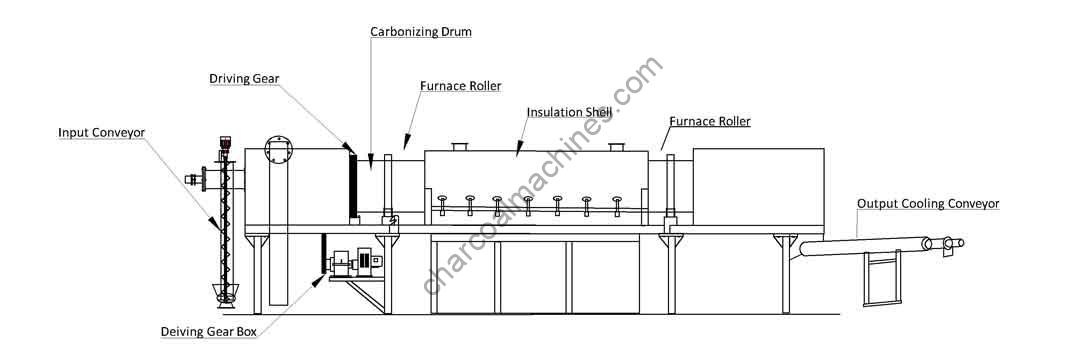

Continuous charcoal carbonization furnace is mainly composed of biomass gasifiers, flue gas purifiers, fan, self-matching gas burner, condensing device, etc.

This rice husk charcoal furnace can work continuously, and the raw material can enter from the inlet and output from the outlet continuously, which saves the cooling time and production time of charcoal.

In addition, this new design of rice husk charcoal machine can realize the recycling of combustible gas produced in the furnace, so it can save a lot of fuel consumption and labor costs.

In the process of operation, when the continuous carbonization furnace starts to heat up, a heat source is needed to heat the carbonization furnace.

One is to use the heat flow generated by the reverberatory furnace to heat the carbonization furnace to achieve the purpose of heating.

Video ya tanuru ya makaa ya mkaa ya kuoka pumba za karanga

Jinsi gani tanuru ya kuoka makaa ya mkaa inafanya kazi?

The biomass is ignited through the gasifier, and the flue gas generated by the gasifier is recovered and purified, cooled into a combustible gas to burn in the carbonization machine.

When the biochar carbonization furnace is heated to a certain temperature, the raw materials in the carbonization furnace begin to carbonize, and the flue gas generated by carbonization is purified and cooled to become a combustible gas, which can be used as the carbonization heat source again.

Coking furnace after about 30 minutes, charcoal powder from the furnace into the cooling system for cooling, charcoal powder temperature rapidly by around 400 ℃ down to about 20-30 ℃, then charcoal powder can be exported and bagged.

Vipengele vya mashine ya kuoka kaboni ya kuendelea

- The continuous charcoal furnace can work continuously, and the raw material can enter from the inlet and output from the outlet continuously, which saves the cooling time and production time of charcoal and has high production efficiency and large output.

- Uendelevu wa tanuru za kaboni umetekelezwa kwa ufanisi wa gesi ya makaa, kaboni inayotiririka, udhibiti wa akili, ukusanyaji wa moja kwa moja wa suluhisho, mvinyo wa mti cyklu ya gesi ya kioevu, na inayoweza kuwaka katika kazi mbalimbali. Imeboresha ubora wa bidhaa na imekabiliana na matatizo ya kaboni ya jadi yenye ufanisi mdogo, kazi kubwa, na uchafuzi mkali wa mazingira, ikitekeleza matumizi bora ya rasilimali zinazoweza kurejeshwa kwa ufanisi.

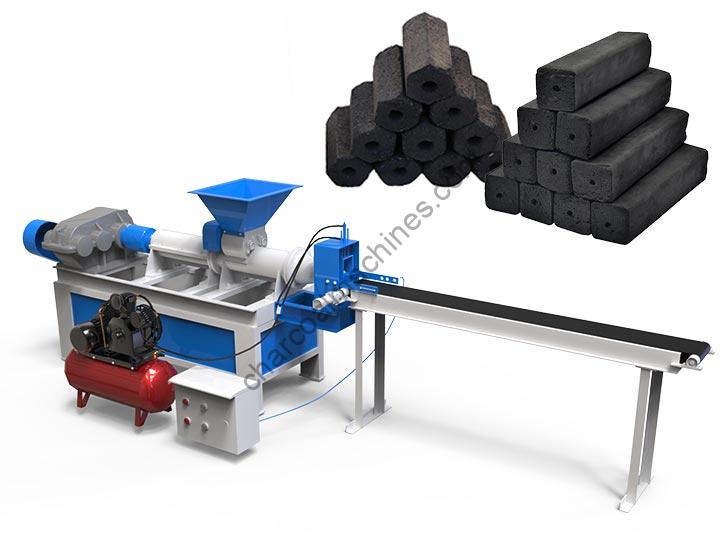

- The continuous carbonization furnace is mainly used in the charcoal production line of first carbonized and then molded. The carbonized charcoal is further crushed by the charcoal crusher and then enters the wheel grinding machine to mix in the binder for stirring. Then after the charcoal briquette machine is made into a finished charcoal bar.

Vigezo vya kiufundi vya tanuru ya kuoka bio-mkaa ya kuendelea

| Model | SL-800 | SL-1000 | SL-1200 |

| Diameter(mm) | 800 | 1000 | 1200 |

| Capacity(kg/h) | 600-800 | 800-1000 | 1000-1200 |

| Main Power(kw) | 18.5 | 18.5 | 20 |

| Carbonization Temperature(℃) | 500-800 | 500-800 | 500-800 |

| Fan Power(kw) | 5.5 | 5.5 | 5.5 |

Soko la mauzo ya moto la tanuru ya kuoka makaa ya mkaa ya Shuliy

This new-designed continuous carbonizing furnace is in hot sale in Southeast Asian countries like Singapore, Indonesia, India, Vietnam, the Middle East countries like Saudi Arabia, Somalia, Iraq, Kuwait, and some Africa countries like Sudan, Morocco, Kenya and Uganda, and so on.

This charcoal machine has a wide usage for turning peanut shells, coconut shells, rice husk, sawdust, and other biomass wastes into high-quality charcoal.

The environment-friendly carbonization furnace is one kind of charcoal machine equipment that can carry on the continuous carbonization and the massive production of charcoal.

With large output, this continuous carbonizing furnace is widely used in the biomass charcoal production lines. It can be used with carbonization machine equipment, such as crusher, dryer, sawdust briquettes machine, to produce high-quality charcoal.

In addition, the furnace can directly and continuously carbonize raw materials, save carbonization time, improve carbonization efficiency and charcoal output.

The production capacity of the continuous carbonization furnace ranges from 300kg/h to 900kg/h. This continuous rice husk charcoal machine can bring you big profits that you can’t imagine.

Jinsi ya kutengeneza makaa ya mchele wa pumba za karanga na mashine ya makaa ya mkaa?

Ukaguzi wa kawaida wa tanuru ya kuoka makaa ya mchele wa pumba za karanga

Most of the charcoal producers, will not feel strange about the continuous carbonization furnaces. Because the continuous type carbonization furnace is widely used in charcoal production.

Almost all the agricultural and forestry wastes can be carbonized by this charcoal machine, like sawdust, rice husk, coconut shell, peanut shell, straw stems, and so on. Besides, can, tin foil, aluminum foil paper, and other materials can also be carbonized by the continuous carbonization furnace.

Although this coconut shell charcoal carbonizing machine is very practical, if there is no regular shutdown inspection and maintenance in the daily production, the machine’s working efficiency will be reduced and its service life will be affected. Therefore, it is necessary to take an eye on the good maintenance of the carbonization furnace.

Jinsi ya kudumisha tanuru ya kuoka makaa ya mkaa ya kuendelea?

Katika uzalishaji wa makaa ya mkaa, kulingana na mahitaji, wakati mwingine huenda kwenye tanuru ya makaa ya mkaa kwa ukaguzi wa muda mfupi wa matengenezo na ukarabati. Matengenezo ya kawaida na ukaguzi pekee yanaweza kuhakikisha uendeshaji wa mashine kwa ufanisi na kupunguza kiwango cha kushindwa. Haya ni baadhi ya maelekezo ya ukaguzi wa kawaida wa tanuru ya kuoka makaa ya mkaa.

Kagua wakati wa kusimamishwa kwa muda mfupi

Baada ya mashine kusimama, mashine yote iko katika hali ya joto. Ikiwa mwili wa silinda haugeuzwi mara kwa mara, mstari wa katikati wa mwili wa silinda unaweza kupinda. Geuza silinda kwa mzunguko ni kazi muhimu na makini kuhakikisha kuwa mstari wa katikati haupindwi.

Kwa kusudi hili, inashauriwa: Katika nusu saa ya kwanza baada ya kusimama, geuza mwili wa silinda robo mara kila dakika 1-5; Katika saa ya kwanza baada ya kusimama, geuza mwili wa silinda robo mara kila dakika 5-10.

Kusimamishwa kwa muda mrefu na ukaguzi

- Baada ya mashine kusimama, geuza mwili wa silinda kwa mzunguko mara kwa mara kulingana na masharti yaliyoelezwa hapo juu hadi ikachemka kabisa.

- Ukaguzi baada ya kufunga: angalia bolt zote za muunganisho kwa ulegevu na uharibifu, hasa zile zilizo na ring gear kubwa. Angalia kama kuna nyufa kwenye welds za silinda na plasta ya nyuma. Angalia kama mafuta ya lubrication kwenye kila pointi ya lubrication yanahitaji kubadilishwa, kusafishwa, au kuongezwa. Ikiwa yanahitaji kubadilishwa, mafuta yaliyobaki yanapaswa kutiririka, kusafishwa, na kujazwa mafuta mapya.

Lubriketi na baridi

Kazi nyingine muhimu ya kudumisha mashine ya kuoka kaboni ya kuendelea ni kutoa lubrication nzuri kwa sehemu zinazohamia za mashine hii ya makaa ya mkaa, ili kuongeza maisha ya huduma ya sehemu hizo, na kupunguza gharama za matengenezo.

Video ya tanuru ya makaa ya mkaa ya pumba za karanga

Lubrication ya mashine ya kuoka makaa ya mkaa

- Lubrication ya mafuta na vaseline inapaswa kutumika kwa usahihi. Bidhaa mbadala lazima ikidhi mahitaji ya utendaji wa vaseline uliobainishwa, na mafuta yenye unene wa juu pekee ndiyo yanayoweza kubadilisha mafuta yenye unene wa chini.

- Kagua kiwango cha mafuta mara moja kwa zamu. Ikiwa kiwango cha mafuta kimepungua hadi kiwango cha chini cha skala ya kiashirio cha kiwango cha mafuta, lazima ijazwe mara moja hadi kiwango cha juu cha kiashirio.

- Baada ya kusimama kwa muda mrefu, kabla ya kuanza, mafuta lazima yawe yamewekwa kwenye bearing ya kuteleza ya roller kwa sufuria ya mafuta, kisha anza.

Zaidi ya hayo, ni muhimu kuzingatia kwamba wafanyakazi wa matengenezo wanapaswa kuzingatia bearings za roller za mfumo wa baridi. Uso wa roller huwekwa baridiwa na maji yanayotiririka kutoka kwa kiti cha roller.

Urefu wa uso wa maji wa tanki la maji unaweza kudhibitiwa kwa kugeuza bomba la PVC. Wakati wa ukosefu wa muda mrefu au kusimama kwa majira ya baridi, tunapaswa kuachilia maji yote ya baridi, ili kuepuka baridi inayosababishwa na nyufa za kupanua kwa bomba.

Jinsi ya kusindika kwa kina makaa ya mchele kutoka kwa tanuru ya makaa ya mkaa ya kuendelea?

Kuchanganya unga wa makaa ya mawe

We can grind coconut shell charcoal, bamboo chip charcoal, wood chip charcoal, rice husk charcoal, etc. into fine charcoal powder by using a charcoal grinder and Raymond mill, which are used to process various briquette charcoal products of different specifications.

Kusukuma na kubana poda ya makaa ya mkaa

Use charcoal briquettes extruder machine to process charcoal briquettes in a quadrangular or hexagonal prism shape.

Use different types of hookah charcoal press machines to make square and round hookah charcoals. The size, pattern, and shape of hookah charcoal can be customized.

The barbecue charcoal press machine can be used to squeeze the charcoal powder into spherical, oval, or pillow-shaped barbecue charcoal briquettes.

This new type of compressed charcoal making machine can squeeze charcoal powder or coal powder into honeycomb or charcoal bricks.

Mifano ya wateja wa mashine hii ya kuoka makaa ya mkaa ya kuendelea

Kiwanda cha Tanuru ya Kaboni cha kg 1000/h Kilimshwa hadi Congo

Maskinen för tillverkning av kokosnötskalaktiven installerad och satt i produktion i Thailand

Karibu wateja wa India watembelea kiwanda cha mashine ya kutengeneza makaa ya mawe cha Shuliy!

Video ya maoni kutoka kwa kiwanda cha makaa ya mkaa cha Malaysia

Tanuru ya kuoka makaa ya mkaa ya kuendelea ya 1t/h iliyosafirishwa hadi Uingereza

Taarifa

Kolsockerpinnarförpackningsmaskin för förpackning av grillkol kvantitativt

Mashine hii ya kufunga briquettes za makaa kwa kiasi inaweza kuwa…

Mashine ya Kukata Miti kwa Uzalishaji wa Mbao Makubwa

Mashine ya kusaga makaa ya mkaa wa mbao kwa mwelekeo wa mwelekeo ni…

Honeycomb Coal Briquette Production Line | Briquettes kolbearbetningsanläggning

Mstari wa uzalishaji wa briquettes za makaa ya nyuki

Mstari wa Utengenezaji wa Briquettes za Sawdust za Mbao | Kiwanda cha Mbao za Moto za Pini Kay

Mstari wa uzalishaji wa briquettes za vumbi la mbao kwa ujumla hu extrude…

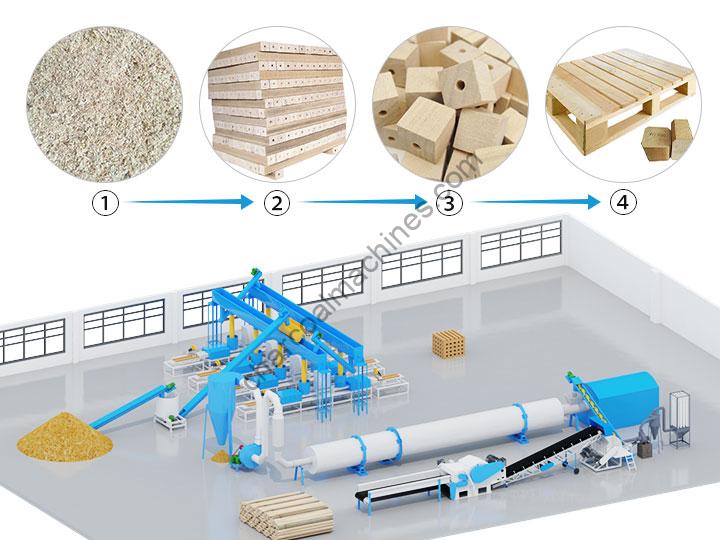

Komprimerad träpallproduktionslinje

Mstari wa uzalishaji wa pallet za mbao zilizobandikwa ni…

Kolsfagnsmaskin: den ultimata guiden till högavkastande biokolproduktion

Mashine mpya ya kutengeneza makaa ni bora…

Hookah Shisha-kolsproduktionslinje | Runda & Kub briquettillverkning

Mstari wa uzalishaji wa shisha hookah charcoal umeundwa...

Träblockproduktionslinje för tillverkning av pressade träpallblock

Mstari wa uzalishaji wa kuta za mbao unaweza kushughulikia…

Komprimerad träpallmaskin för formad pallproduktion

Mashine ya kupakia makapi ya mbao ni sehemu...

Maoni 8