A complete charcoal processing line was installed in Lebanon

The specific configurations of the charcoal processing lines purchased by different customers are not the same, because different customers have different processing needs. The Shuliy factory can customize the most cost-effective charcoal production plan for customers according to customer needs and investment budget. Recently, the full set of charcoal processing lines exported from the Shuliy factory to Lebanon have been installed and can enter formal production.

The communication process of the Lebanese charcoal machine order

The Lebanese customer started a charcoal production business in partnership with his cousin. They sought out many charcoal machine manufacturers for consultation in the early stages of investment. This Lebanese customer contacted us through our charcoal production line YouTube video. They were very interested in the full set of charcoal plant videos we provided.

Our engineers and sales managers quickly negotiated with them the processing flow of the charcoal production line and the list of required equipment. The output of the charcoal line required by this Lebanese customer is about 2 tons per day, mainly producing sawdust briquettes charcoal.

Although the Lebanese customer quickly confirmed the details of the εξοπλισμός παραγωγής κάρβουνου, they did not pay immediately. This is because they must have certain environmental protection certificates to carry out the charcoal processing business in the local area.

The charcoal processing process does produce a small amount of smoke and dust. In order to solve the customer’s problem, we recommend very efficient smoke purification equipment to ensure that the smoke and dust generated during the charcoal processing process are filtered to avoid environmental pollution. The Lebanese customer was very satisfied with our proposal. After they got the local qualification certificate, they paid us and placed the order soon.

Configuration list of Lebanon charcoal processing line

| No. | Item & parameters | Picture | quantity |

| 1 | WOOD SPLITTER Model: SL-P42 Power:15kw Dimension:4200*700*1300mm Weight:2.2t |  | 1 |

| 2 | WOOD CRUSHER Model: SL-1000 Diesel type Horse power:150hp Capacity:3t/h The feeding inlet size is 26cm in diameter Output size: less than 5 mm |  | 1 |

| 3 | FINE POWDER MACHINE Model: SL-Q60 Power:22kw Capacity:800-1000kg per hour Weight:1t Dimension:3*2.3*1.8m Hammers: 30pcs Including dust remover bag(5pcs) Cyclone diameter:1 meter |  | 1 |

| 4 | SCREW CONVEYOR Model:SL-3 M Power:1.5 kw Dimension:3800*500*500mm |  | 1 |

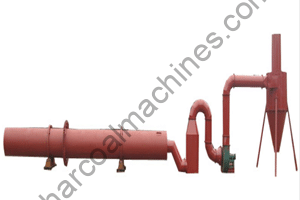

| 5 | ROTARY DRYER Model:SL-D800 Output:600-800kg/h Power:8kw Dimension:15000*1500*3500mm |  | 1 |

| 6 | SCREW CONVEYOR Model:SL-3 M Power:1.5 kw Dimension:3800*500*500mm |  | 1 |

| 7 | SCREW DISTRIBUTOR Length:4m Power:4kw Weight:400kg Dimension:4000*400*900mm |  | 1 |

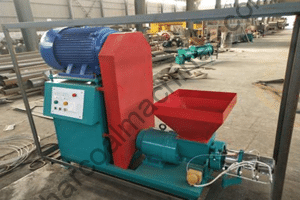

| 8 | SAWDUST BRIQUETTE MACHINE Model:SL-500 Power:18.5 kw Capacity: 300 kg/h Spare parts: 1.Screw 2.Heating coil 3.Briquetting cylinder |  | 3 |

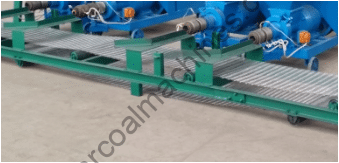

| 9 | MESH CONVEYOR Dimension:5000*650*400mm Power:1.5kw Weight:400kg |  | 1 |

| 10 | CARBONIZATION FURNACE Model:SL-Q1800 Dimension:4500*1900*2300mm Capacity:2t charcoal per day |  | 1 |

2 σχόλια