メッシュベルト乾燥機は一般的な連続乾燥装置です。化学工業、食品工業、医薬品工業、建築材料工業、電子工業などで広く使用されています。

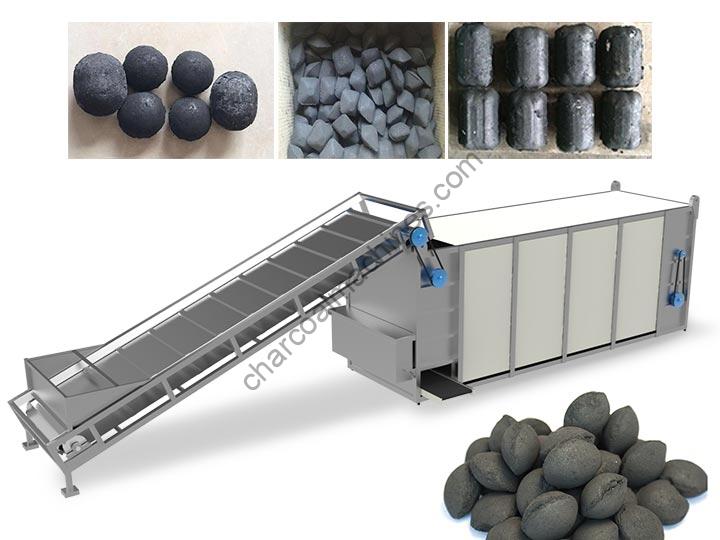

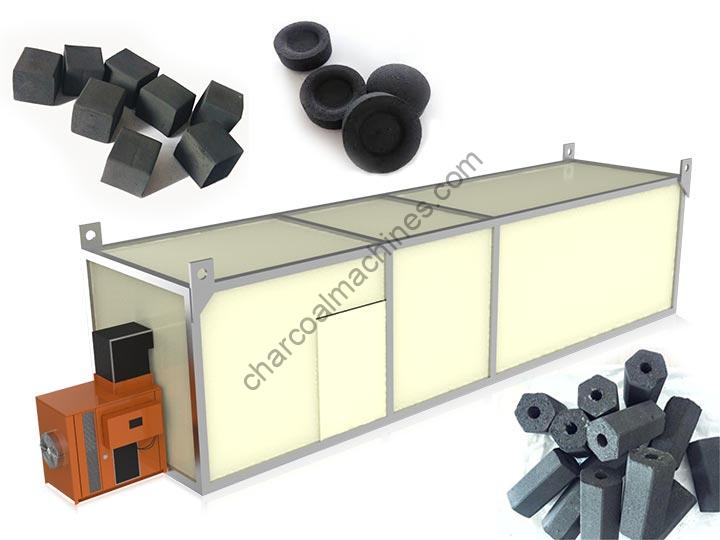

特に、良好な通気性を持ち、ピース、ストリップ、粒状の形状の野菜や果物、米、ハーブなどの乾燥に適しています。また、チャコールブリケット機や炭球プレス機で製造されたシーシャやバーベキュー炭のような炭ブリケットの乾燥も可能です。

原料は、スタートディストリビューターや振動ベルトなどの適切なメカニズムを通じてコンベヤーベルトに広げることができます。コンベヤーベルトは、1つまたは複数の乾燥ユニットからなるチャネルを通過します。

各乾燥ユニットには空気加熱循環システムが装備されており、各乾燥ユニットには一つまたは複数の除湿システムがあります。コンベヤーベルトが通過する際に、熱風は上下に動きながら材料を均一な速度で乾燥させます。

メッシュベルト乾燥機の主構造と動作原理

ベルト乾燥機は、ルバーブ、サルビア、ジンセン、マドラーなどの中国ハーブ薬の乾燥にも使用できます。乾燥したタケノコ、菌類、ニンニク、花、乾果、野菜、きのこ、サツマイモ、トウモロコシ、エンドウ豆、豆、ココナッツなどにも適しています。ビタルや菌類などの農産物や副産物の乾燥にも使用できます。その際は、実際の状況に応じて乾燥温度と湿度を設定するだけです。お客様の実際の生産状況に応じて乾燥プロセスも調整可能です。

特にシーシャ炭やバーベキュー炭またはコールボールのための炭素生産ラインについては、メッシュベルト乾燥機も独自の乾燥効果を持っています。メッシュベルト乾燥機は、主に押し出された完成炭棒や炭、コールボールをコンベヤーを通じて平らなコンベヤーに直接届けます。完成品は、平らなコンベヤーの上端にあるスクレーパーを通じて乾燥機に均一に分散され、球の通気性を向上させ、乾燥効果を達成します。

メッシュベルト乾燥機の主動作原理は、材料をメッシュベルトに均一に広げ、乾燥機内の伝送装置によって前後に動かすことです。熱風は材料を通過し、水蒸気は湿った穴から排出され、乾燥の目的を達成します。メッシュベルトは12-60のワイヤーメッシュベルトで作られ、箱の長さは標準セクションで構成されています。場所を節約するために、乾燥機は多層にすることもでき、一般的には二部屋三階や二部屋五階の構成で、長さは6-40m、実効幅は0.6-3.0mです。

材料は乾燥のためにゆっくりと頭から乾燥機に入ります。材料の種類と水分含有量に応じて、メッシュベルトの速度を決定できます。乾燥機内の気流は負圧と多孔性の吸気を採用し、効果的な乾燥エリアを確保し、風速を均一に分散させて乾燥効果を向上させます。最良の乾燥効果と適切な出力を得るために、材料の水分含有量、メッシュベルトの速度、風量、空気温度は適切で合理的な有機的組み合わせでなければなりません。

炭ブリケット用メッシュベルト乾燥機の利点

- メッシュベルト乾燥機は、材料の滞留時間と供給速度を調整して最良の乾燥効果を得ることができます。

- 柔軟な装置構成。メッシュベルト乾燥機は、メッシュベルト洗浄システムや材料冷却システムを使用でき、乾燥効率が向上します。

- メッシュベルト乾燥機はほとんどの空気循環を利用でき、省エネルギー性が高いです。

- 乾燥機の独自の空気分配装置により、熱風の分布がより均一になり、製品の品質の一貫性を確保します。

- 熱源は蒸気、熱伝導油、熱風ストーブ、またはガスストーブが使用できます。

技術パラメータ 炭素乾燥機の

| モデル | SL-6 | SL-8 | SL-10 | SL-12 | SL-16 | SL-20 | SL-24 | SL-30 |

| ベルトの幅 | 600mm | 800mm | 1000mm | 1200mm | 1600mm | 2000mm | 2400mm | 3000mm |

| 乾燥セクションの長さ | 6-12 | 6-12 | 6-16 | 8-16 | 8-22 | 10-26 | 12-30 | 12-40 |

| 給料セクションの長さ | 1 | 1 | 1 | 1 | 1 | 1.5 | 1.5 | 2 |

| 伝送セクションの長さ | 1 | 1 | 1 | 1 | 1 | 1.5 | 1.5 | 2 |

| 乾燥エリア | 3.6-36㎡ | 4.8-48㎡ | 6-80㎡ | 7.2-96㎡ | 12.8-105.6㎡ | 20-260㎡ | 28.8-360㎡ | 36-600㎡ |

| ユニット数 | 1-5 | |||||||

| インターレラースペーシング | 400-600 mm | |||||||

| 積載能力 | 90-200 kg/㎡ | |||||||

| 温度 | 炭素鋼≤400°C、ステンレス鋼≤600°C | |||||||

| 熱源 | 硬木、電気、蒸気 | |||||||

| 運転速度 | 0.06-1m/min | |||||||

| 伝送パワー | 1.1-2.2 kW | 1.1-2.2 kW | 1.1-2.2 kW | 1.1-3kw | 1.5-3 kW | 1.5-4 kW | 3-7.5 kW | 5-11 kW |

| マッチング装置 | 搬送装置、空気加熱炉、ダスト除去装置、ダクトファンなど |

ホット商品

バーベキュー炭生産ライン|BBQブリケット処理プラント

バーベキュー炭の生産ラインは主にさまざまな…を処理します

バーベキュ炭ブリケット包装機(定量包装)

この定量炭化ブリケット包装機は…

木材ク Crusher 木材廃材から木屑を作る

木材破砕機は一般的に使用される破砕装置です

成形パレット用木材パレット機

圧縮木パレット機は…の一部です。

動物飼料用小型飼料ペレット機械

小型飼料ペレット機は家庭用です…

ブリケット用カッター(ブリケット炭の必要量に応じて)

炭ブリケットカッターは…に使用されます。

パレットブロック機(パレットブロック製造)

商用木製パレットブロック成形機は…

垂直炭化炉 木炭生産用

空気輸送式炭化炉は現在、…

バイオ炭製造用炭機&生産ライン

炭化機はバイオマス廃棄物を…に変えることができます。

コメント2件