Endonezya'da Kurulu Tam Küp Nargile Kömürü Tesisi

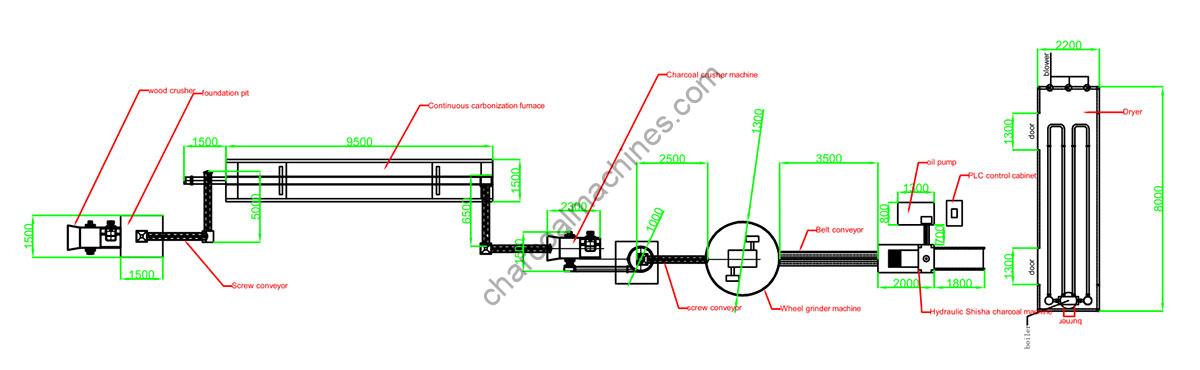

Küp nargile kömürü tesisinin üretim süreci esasen biyokütle ham maddelerinin karbonizasyonu, kömür kırma, karbon tozu karıştırma ve bağlayıcı ekleme, küp kömür şekillendirme, küp kömür kurutma ve diğer üretim aşamalarını içerir. Yuvarlak ve küp nargile kömürü seri üretimi, Güneydoğu Asya ülkelerindeki birçok kömür fabrikasının en çok tercih ettiği yöntem olmuştur. Geçen ay, tam küp nargile kömürü üretim hattımız Endonezya'ya ihraç edilip kuruldu.

Küp nargile kömürü VS yuvarlak nargile kömürü tableti

Nargile kömürü denilince, en çok etkilendiğimiz disk şeklindeki nargile kömürü olmalı. Bu yuvarlak kek şeklindeki şişa kömürü ilk ortaya çıkan ve şişa pazarında kullanılan kömürdür.

Yaygın yuvarlak nargile kömürü çeşitli boyutlarda mevcuttur, örneğin çukur yuvarlak kömür, yazı ve desenli kömür, renkli kömür vb. Yaygın yuvarlak nargile kömürü çapları 30mm, 33mm, 35mm, 40mm, 45mm vb.

Şu anda, nargile kömürü pazarının gelişmesiyle birlikte, çeşitli şekil ve boyutlarda kömürler popüler hale geliyor. Bunlar arasında kare kömür şu anda oldukça popülerdir.

Bu küp nargile kömürü için en yaygın boyutlar 20*20*20mm ve 25*25*25mm'dir. Küp kömür popülerdir çünkü daha küçüktür ve taşınması daha kolaydır.

Neden Endonezya'da küp nargile kömürü işi başlatmalıyız?

Müşteri, Endonezya'nın en büyük tütün şirketi PT Gudang Garam Tbk'den. Bir nargile kömürü işleme işi başlatmayı planlıyorlar. Şirket, satış amacıyla 25mm boyutunda nargile kömürü işlemek istiyor.

Endonezya şirketinin satın alma projesi sorumlusu tarafından bize iletilen küp nargile kömürü tesisi siparişi, makine konfigürasyonu, makine parametreleri, üretim hattı çıkışı, enerji tüketimi gibi tüm detayları doğruladı.

Müşterinin gereksinimlerine göre iki detaylı küp nargile kömürü tesisi çözümü hazırladık. Daha sonra, satın alma sorumlusu teklifimizi şirketin patronuna analiz ve onay için sundu. Patronumuz üretim planımıza onay verdikten sonra, satın alma ekibi bizimle tüm planın detayları ve fiyatı üzerinde müzakerelere başladı.

Endonezya için kömür tesisinin kalitesini nasıl sağlarım?

Ürün kalitesini sağlamak amacıyla, şirket ayrıca sevkiyat öncesinde tüm küp nargile kömürü tesisinin ekipmanlarını denetlemek üzere bir denetim şirketi de davet etti. Sonuçta, ürün denetim sonuçları onlar için çok memnun ediciydi.

Şirketin satın alma ekibi, teklif ettiğimiz fiyat üzerinde %5 indirim talep etti, ancak maliyet gerekçeleriyle dikkatli hesaplama sonrası %3 indirim yapmaya karar verdik.

Endonezya için küp nargile kömürü tesisi parametreleri

| Öğe | Özellikler | Miktar |

| Odun kırıcı makinesi | Model: SL-600 Güç: 30kw Kapasite: Saatte 1000kg Boyut: 1.65*0.75*1.05m Ağırlık: 600kg Gümrük Kodu: 8465990000 | 1 |

| Vida konveyör | Boyut: 4m*0.3m*0.5m Güç:4kw Gümrük Kodu: 8428320000 | 1 |

| Sürekli karbonizasyon fırını | Model: SL-800 Boyut: 9*2.6*2.9m Güç:22kw Kapasite: 300 kg saat başı Ağırlık: 9 ton Gümrük Kodu: 8417809090 | 1 |

| Vida konveyör | Boyut: 4m*0.3m*0.5m Güç:4kw Gümrük Kodu: 8428320000 | 1 |

| Aktarözü kırıcı makinesi | Model: SL-C-600 Güç:22kw Kapasite: 500kg saat başı Kömür tozunun nihai boyutu: 5mm'den az Siklon çapı: 1m Fan dahil, 5 torba toz giderme Gümrük Kodu: 8437800000 | 1 |

| Hava kilidi | Güç:1.5kw | 1 |

| Vida konveyör | Boyut: 4m*0.3m*0.5m Güç:4kw Gümrük Kodu: 8428320000 | 1 |

| Tekerlek değirmen makinesi | Model: SL-1300 Güç:5.5kw Kapasite: 300-400kg saat başı İç çap: 1300mm Boyut: 1350*1350*1400mm Gümrük Kodu: 8474390000 | 1 |

| Kemer konveyör | Boyut: 5m*0.7m*0.7m Güç:2.2kw Gümrük Kodu: 8428330000 | 1 |

| Hydraulic Shisha kömürü makinesi | Basınç:100 ton Kapasite: 44 adet/kez, dakikada 4 kez Ağırlık:2800kg Hydraulic pompa gücü:15kw Ana ünite boyutu:1000*2100*2000mm Besleme gücü:0.75kw Boşaltım gücü:0.75kw Shisha kömürü makinesinin boşaltım konveyörü:800*850*1850mm Kontrol paneli boyutu:530*900*1100mm | 1 |

| Ek kalıp | Şekil: 25mm içeren yuvarlak | 1 |

| Biyokütle brülörü | 1 | |

| Kurutucu makinesi | Boyut: 8.8*2.2*2.2m Malzeme: Renkli çelik, 75mm kaya yünü levha Kapasite: 3 ton kömür/kez, 8-10 saat sürer Biyokütleyi ısı kaynağı olarak kullanmak ve biyokütle brülörü Gümrük Kodu: 8419899090 | 1 |

Endonezya siparişi için yedek parça listesi

Bıçaklar | 12 set |

Çekiçler | 6 set |

Ekran | 4 adet |

Yorum Yok.