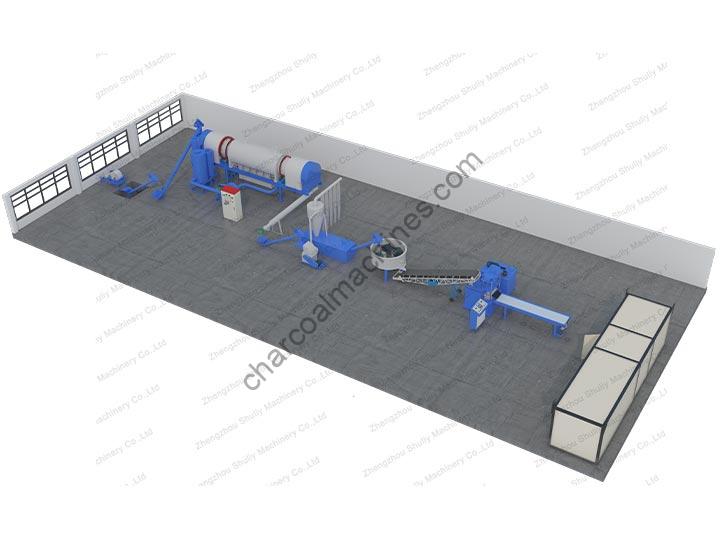

자동 시샤(후카) 숯 생산 라인은 압축, 포장, 건조를 위한 완전 처리 라인입니다. 이 라인의 주요 기계는 시샤 숯 압축기(후카 숯 압축기), 숯 선별 및 포장기, 숯 블록 건조기입니다. 이 상업용 시샤 숯 블록 가공 공장은 노동 비용이 적으며 매우 효율적이며, 많은 유럽 국가들이 산업용 시샤 숯 생산을 위해 좋은 가격에 구매했습니다.

시샤 숯 생산 라인의 주요 구성품

1. 일반 시샤 숯 구형 기계/훼카 숯 압축 기계

시샤 숯 블록을 만들기 위해, 정육면체 시샤 숯과 원형 태블릿 시샤 숯 모두, 슐리 기계는 다양한 종류의 압축기를 제공하며, 생산 요구에 따라 적합한 것을 선택할 수 있습니다. 일반적으로 판매되는 시샤 숯 압축기는 주로 다음과 같습니다:

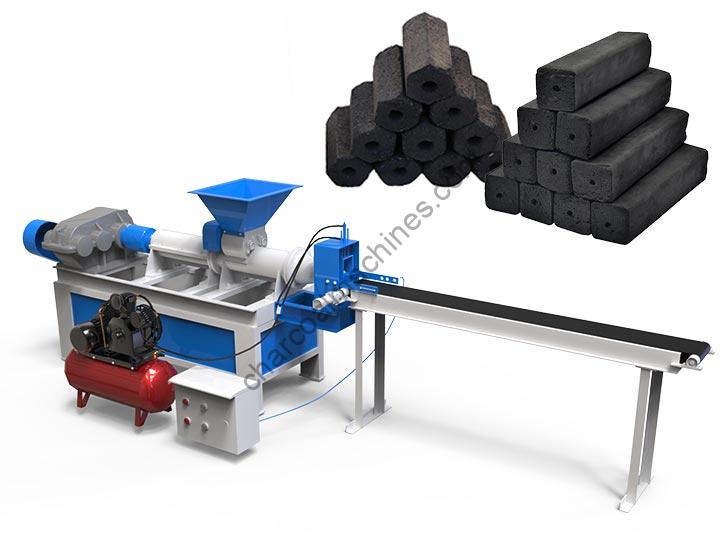

1.1 입체 시샤 숯 압축 기계

이 인기 판매 숯 압축기는 숯 가루 압축기라고도 하며, 다양한 숯 또는 석탄 가루를 일정한 모양으로 압축할 수 있습니다. 고객이 선호하는 모양은 원통형, 사각형, 육각형입니다. 이 압축기는 다기능 숯 제조기이며, 시샤 숯 블록과 바베큐 숯 블록을 매우 효율적으로 만들 수 있습니다. 이 숯 기계로 입방체 시샤 숯을 만들 때, 회전 절단날이 있는 자동 절단기와 함께 사용하여 긴 숯 막대를 작은 입방체로 자를 수 있습니다.

1.2 유압 원형/정사각형 구형 제조 기계

이 유형의 후카 숯 압축기는 유압 형과 기계식 두 가지로 설계할 수 있습니다. 유압 시샤 숯 압축기는 특수 유압 프레스 시스템을 채택하여 잘 혼합된 숯 가루를 원형 태블릿으로 압축합니다. 높은 작업 효율을 가지고 있으며, 시간당 약 15000-2700개의 시샤 블록을 생산할 수 있습니다.

이 유압형과 달리, 기계식 압축기는 기계적 전달력을 이용하여 숯 가루를 압축하여 블록으로 만듭니다. 압축 후, 완성된 숯 태블릿은 자동 컨베이어로 밀려 노동자가 수집할 수 있습니다. 이 두 가지 시샤 숯 기계는 원형, 사각형, 하트 모양, 육각형, 문자형 등 다양한 모양으로 맞춤 제작이 가능합니다.

1.3 빠른 원형 훼카 숯 구형 기계

이 기계는 슐리 기계가 개발한 최신 태블릿 압축기이며, 시장에 출시되자마자 많은 고객에게 호평을 받았습니다. 매우 효율적이며 다른 기계와 함께 생산 라인에서 자동화할 수 있습니다. 시샤 숯 압축기계의 주요 부분은 고속 회전하는 금형이 있는 디스크 구조로 구성되어 있습니다. 작동 시, 탄소 가루는 빠르게 압출되어 구조를 통과하며 해당 트레이에 떨어집니다.

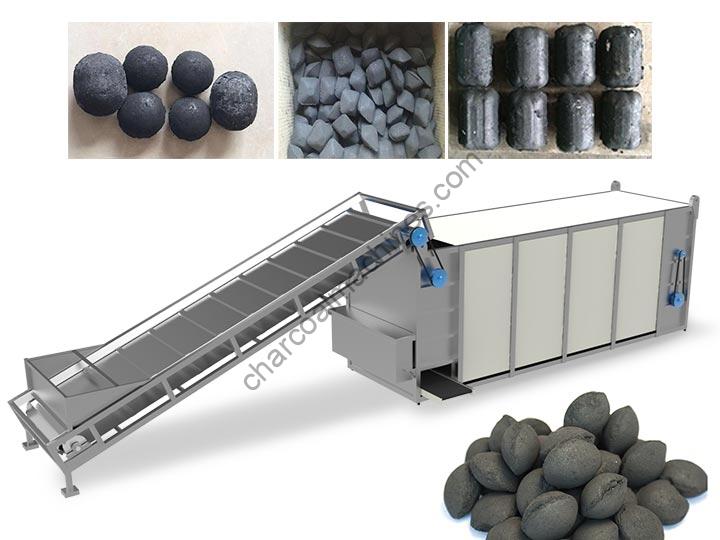

2. 시샤 숯 구형 건조기 기계/연속 건조 설비

우리는 두 가지 유형의 숯 건조기를 설계했습니다: 메시 벨트 숯 건조기와 효율적인 건조실로, 모든 종류의 숯 블록(바베큐 숯, 숯 또는 석탄 공, 후카 숯 등)을 건조할 수 있습니다. 메시 벨트 타입은 연속 건조 설비이며, 전기, 석탄, 가연성 가스 등으로 가열할 수 있습니다. 새로 설계된 건조실은 배치별 숯 블록 건조에 적합합니다. 이 두 가지 건조기는 허브, 과일, 채소 등 다른 재료의 건조에도 사용할 수 있습니다.

3. 시샤 숯 구형 제조 기계 순서 분류기

이 선별기는 시샤 숯 포장 라인에서 블록을 빠르게 선별하는 데 널리 사용됩니다. 이 장비는 주로 공급 부분과 자동 분배 장치로 구성되어 있습니다. 시샤 숯 태블릿이 공급판에 놓이면 일정한 속도로 위로 운반됩니다. 운반 과정에서 노동자는 파손된 블록을 선별할 수 있습니다. 이후, 이 선별기의 자동 분배 장치는 각 배치별로 10개씩 후카 블록을 포장하기 위해 분배합니다. 각 그룹의 숯 블록 수는 맞춤형으로 조정 가능합니다.

4. 자동 시샤/훼카 숯 포장 기계

이 수평형 포장기는 다양한 재료를 포장하는 다기능 설비입니다. 작동 시 밀봉기와 함께 사용할 수 있으며, 이 숯 포장기는 자동화 수준이 높고, 자동 공급 및 배출, 조작 및 유지보수가 용이합니다. 포장 후, 시샤 숯 제품은 노동자가 큰 박스에 담아 이동하기 쉽도록 수집할 수 있습니다.

시샤/후카 숯 포장 효과 디스플레이

인기 상품

메쉬 벨트 건조기 for 연속 브리켓 건조

메쉬 벨트 건조기는…

목재 껍질 벗기기 기계

목재 디바커 기계, 통나무…

숯 석탄 분쇄기 | 숯 가루 분쇄기 기계

숯 크러셔 기계는 주로 다양한 것을 분쇄할 수 있습니다…

고효율 톱밥 브리켓 기계 for 판매

산업용 톱밥 압축기계는 주로…

목재 가루 분쇄기 for 목재 가루 만들기

목재 분말 기계는…

모든 목재 폐기물에서 톱밥을 만드는 목재 분쇄기

목재 분쇄기는 일반적으로 사용되는 파쇄 장비입니다…

시샤 후카 숯 생산 라인 | 원형 & 큐브 브리켓 제조

시샤 후카 숯 생산 라인은 설계되어 있습니다…

숯 석탄 압축기 기계 for 숯 공장

숯 압축기계는 숯과 석탄을 압출할 수 있습니다.

수직 탄화로 for 경재 숯 생산

현재 수평 탄화로는…

9개의 댓글