Máquina Industrial de Pellets de Madeira à Venda

A extrusora de pellets de madeira é um equipamento especializado projetado para converter madeira bruta em pellets de combustível de alta densidade. Este moinho de pellets é projetado para confiabilidade operacional e eficiência, produzindo pellets uniformes de forma consistente.

Máquina Industrial de Pellets de Madeira à Venda

A extrusora de pellets de madeira é um equipamento especializado projetado para converter madeira bruta em pellets de combustível de alta densidade. Este moinho de pellets é projetado para confiabilidade operacional e eficiência, produzindo pellets uniformes de forma consistente.

Características em Destaque

Procurando uma máquina de pellets de madeira confiável para transformar resíduos de biomassa como serradura, cavacos de madeira e palha em combustível de alto valor? Como fabricante líder, oferecemos uma gama completa de fabricantes de pellets de madeira — desde modelos de pequena escala para uso doméstico até grandes moinhos de pellets de madeira industriais para produção em massa. Transforme seus resíduos em lucro e solicite uma cotação personalizada hoje.

OBTENHA UMA COTAÇÃO GRATUITA AGORA

O que é uma máquina de pellets de madeira e como funciona?

Uma máquina de pellets de madeira (também conhecida como fabricante de pellets de madeira ou pelletizador de biomassa) é projetada para comprimir materiais de biomassa de baixa densidade em pellets de combustível sólido de alta densidade. Ela processa eficientemente culturas, resíduos florestais, serradura e cavacos de madeira em um combustível granular com alta gravidade específica e textura dura.

Os pellets de biomassa finais têm características excelentes: são fáceis de acender, possuem alto valor calorífico e produzem uma cinza muito baixa após a combustão. Isso os torna um combustível limpo, sanitário e de alta qualidade que pode substituir o carvão em caldeiras industriais e domésticas, bem como para cozinhar e aquecer civis.

O Processo de Trabalho

Quando a máquina de pellets de madeira está operando, o processo é o seguinte:

- Alimentação: Matérias-primas (como serradura de uma triturador de madeiraCaem verticalmente da entrada de alimentação e são distribuídos uniformemente na superfície do molde por uma roda de prensagem rotativa.

- Prensagem e Moldagem: O material é continuamente forçado através dos orifícios do molde pela imensa pressão dos rolos. Durante este processo, o material é submetido a alta pressão e alta temperatura, causando alterações físicas e químicas que ativam a lignina natural da madeira para atuar como aglutinante.

- Corte e Descarga: Um corpo sólido e cilíndrico é continuamente extrudido pelos orifícios do molde. Um cortador interno então corta esses cilindros em pellets uniformes, que são descarregados pela porta de saída, completando o processo de pelletização.

Assista ao nosso extrusor de pellets de madeira em ação

Veja todo o processo de fabricação de pellets de madeira, desde a matéria-prima até o produto final.

Qual máquina de pellets de madeira é adequada para você? (Modelos e aplicações)

Escolher a máquina certa depende totalmente dos seus objetivos de produção. Oferecemos modelos para todas as escalas de operação.

1. Pequena Máquina de Pellets de Madeira para Uso Doméstico

Ideal para pequenas fazendas, oficinas ou proprietários que desejam produzir seu próprio combustível para fogões de pellets. Estes compactos fabricantes de pellets de madeira são fáceis de operar e requerem espaço mínimo.

- Capacidade: 50 – 300 kg/h

- Ideal para: Produção de combustível DIY, pellets caseiros, pequena escala de alimentação animal.

2. Máquina Comercial de Pellets de Madeira

Projetado para pequenas e médias empresas que desejam vender pellets de madeira localmente ou usá-los em caldeiras comerciais. Essas máquinas oferecem um excelente equilíbrio entre produção e investimento.

- Capacidade: 300 – 800 kg/h

- Ideal para: Negócio de venda de pellets, grandes fazendas, pequenas fábricas.

3. Moedor de Pellets de Madeira Industrial & Linha de Produção

Para fabricação em grande escala, nossos moinhos industriais de pellets de madeira são o núcleo de uma linha completa de produção de pellets de madeira . Esses sistemas robustos são construídos para operação 24/7 e alta produção.

- Capacidade: 1 – 5 toneladas/h (ou mais)

- Ideal para: Produção em massa para exportação, centrais de biocombustíveis.

Especificações técnicas

| Modelo | Capacidade (t/h) | Potência (kW) | Diâmetro do pellet (mm) | Matérias-primas aplicáveis |

|---|---|---|---|---|

| ZLSP-200 (Pequeno) | 0.1 – 0.2 | 7.5 | 6, 8, 10 | Serradura, palha, casca de arroz |

| ZLSP-400 (Comercial) | 0.4 – 0.6 | 30 | 6, 8, 10 | Cavacos de madeira, serradura, casca de árvore |

| MZLH-520 (Industrial) | 1.5 – 2.5 | 132 | 6, 8, 10 | Toda biomassa, incluindo madeira dura |

Nota: As especificações são para referência. Oferecemos soluções personalizadas.

Preço da máquina de pellets de madeira

O preço de uma máquina de pellets de madeira pode variar de $2.000 para um modelo de uso doméstico pequeno até mais de $100.000 para uma linha de produção industrial completa. O custo final da máquina de pellets de madeira depende da capacidade, marca do motor e se você precisa de equipamentos auxiliares como triturador, secador, resfriador e empacotador. Entre em contato para uma cotação precisa, sem compromisso, adaptada às suas necessidades.

Principais recursos e vantagens

- Baixo Consumo de Energia, Alta Produção: Com uma fonte de energia otimizada (por exemplo, 80KW para uma máquina de 1-1,5 toneladas/h), os nossos designs reduzem o consumo de energia em 10-20% em comparação com produtos similares, maximizando a sua rentabilidade.

- Baixo Custo de Mão de Obra & Alta Eficiência: Um único conjunto de equipamento requer apenas 2-3 pessoas desde a produção até ao embalamento. As máquinas são projetadas para operação e manutenção simples, minimizando o tempo de inatividade.

- Produção Ecológica: O design interno apresenta um sistema integrado de remoção de poeira, garantindo baixo ruído e sem emissão de fumaça ou esgoto durante o processo de produção.

- Durável & Amplamente Aplicável: As nossas máquinas têm uma baixa taxa de desgaste durante o uso e uma pegada pequena, tornando-as adequadas para locais de produção urbanos e rurais.

- Sucesso Global Comprovado: Instalámos com sucesso mais de 500 linhas de pellets em mais de 30 países, incluindo Canadá, EUA e Malásia.

Estrutura detalhada da máquina

Nossa máquina vertical de pellets de madeira possui estrutura compacta e aparência bonita, facilitando o transporte no local de trabalho. É composta por uma base de máquina de pellets, uma caixa de redução grande, uma sala de rolamentos, uma tampa de alimentação, uma parte de descarga, um motor, um conjunto de rolos de pressão e um molde. O motor elétrico é conectado diretamente ao eixo do redutor. Após uma mudança de direção de 90°, o motor aciona um eixo vertical, que por sua vez faz os rolos girarem ao longo da superfície interna do molde para completar o processo de prensagem.

Dicas de manutenção da máquina de pellets de madeira

- Durante a produção, lubrifique o rolo de pressão a cada 2 horas usando um rolo manual na extremidade do eixo principal.

- Antes de cada sessão de trabalho, encha o parafuso e o rolamento de agitação com lubrificante No. 2.

- Encha o redutor de agitação da máquina com graxa de base de lítio de dissulfeto de molibdênio a cada seis meses.

- Os rolamentos dos eixos do alimentador e do agitador devem ser limpos e ter seu óleo trocado a cada dois anos.

- Para armazenamento a longo prazo, pressione materiais oleosos e não deterioráveis através da máquina para preencher os orifícios do molde. Limpe todas as partes de resíduos de material e cubra a máquina com uma capa de plástico.

Perguntas Frequentes (FAQ)

Que matérias-primas podem ser usadas?

Nossas máquinas podem processar uma vasta gama de biomassa, incluindo serradura, lascas de madeira, cavacos, palha, casca de arroz, casca de amendoim e mais. O teor de umidade ideal é de 12-18%.

Quanto custa uma máquina de fazer pellets de madeira?

Como mencionado, os preços variam bastante. Uma máquina pequena começa em torno de 2.000 dólares, enquanto linhas industriais representam um investimento significativo. Entre em contato conosco com seus requisitos de matéria-prima e capacidade para uma cotação precisa.

Você tem máquinas de pellets de madeira à venda no Canadá?

Sim, enviamos para todo o mundo, incluindo Canadá. Temos vários clientes na Colúmbia Britânica e Ontário e podemos cuidar de toda a logística e liberação alfandegária do seu pedido.

Qual é o processo completo de fabricação de pellets de madeira?

Uma linha de produção completa geralmente inclui: Trituração/Quebra → Secagem → Pelletização → Resfriamento → Peneiração → Embalagem.

Pronto para iniciar seu negócio de pellets?

Nossos especialistas estão prontos para ajudá-lo a escolher a máquina perfeita e fornecer uma cotação detalhada. Entre em contato conosco via chat online ou email para começar seu projeto!

Produto em destaque

Máquina de Blocos de Paletes de Madeira para Fabricação de Blocos de Paletes

Máquinas comerciais de fabricação de blocos de paletes de madeira podem extrudar…

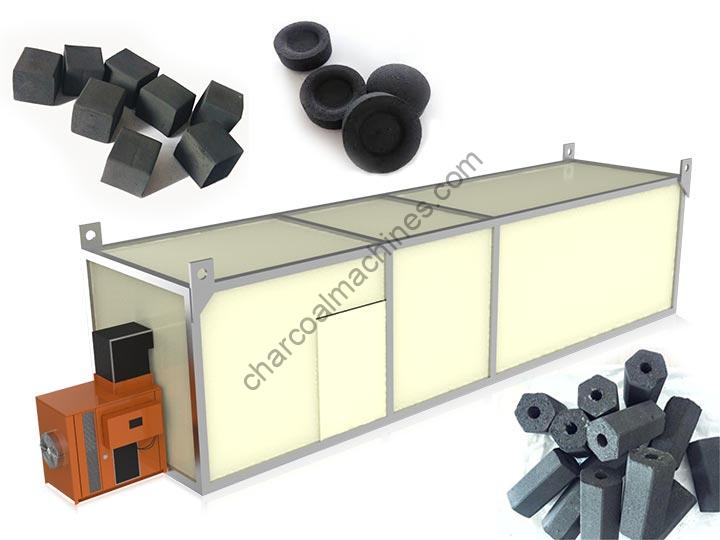

Linha de Produção de Carvão para Churrasco | Planta de Processamento de Briquetes para BBQ

A linha de produção de carvão para churrasco processa principalmente várias…

Triturador de Tambor para Produção em Massa de Chips de Madeira

A máquina trituradora de aparar madeira pode ser…

Máquina de Carvão & Linha de Produção para Fazer Biochar

As máquinas de fabricação de carvão podem transformar resíduos de biomassa,…

Triturador de Carvão de Carvão | Máquina de Moagem de Pó de Carvão

A máquina de triturar carvão pode pulverizar principalmente vários…

Máquina de Secagem de Carvão em Lote com Boa Performance

A máquina de secagem de carvão é usada principalmente para…

Cortadores de Briquetes para fazer briquetes de carvão conforme necessário

A máquina de corte de briquetes de carvão é usada para…

Equipamento de Purificação de Gases de Combustão

Purificação de gases de combustão No passado, devido…

Máquina de Prensagem de Briquetes de Churrasco de Forma Redonda e Travesseiro

Máquina de prensagem de carvão de churrasco pode fazer carvão comprimido…

4 comentários