Yüksek Verimli Tozdan Kömür Pelet Makinesi Satışta

Testere tozu, pirinç kabukları ve odun atıklarını değerli yakıt kömürlerine dönüştürün. Güçlü testere tozu kömürleme makinemiz, bertaraf maliyetlerini azaltır ve yeni bir gelir akışı oluşturur, yüksek YG sağlar. Ücretsiz teklifinizi alın bugün!

Yüksek Verimli Tozdan Kömür Pelet Makinesi Satışta

Testere tozu, pirinç kabukları ve odun atıklarını değerli yakıt kömürlerine dönüştürün. Güçlü testere tozu kömürleme makinemiz, bertaraf maliyetlerini azaltır ve yeni bir gelir akışı oluşturur, yüksek YG sağlar. Ücretsiz teklifinizi alın bugün!

Özellikler Hızlı Bakış

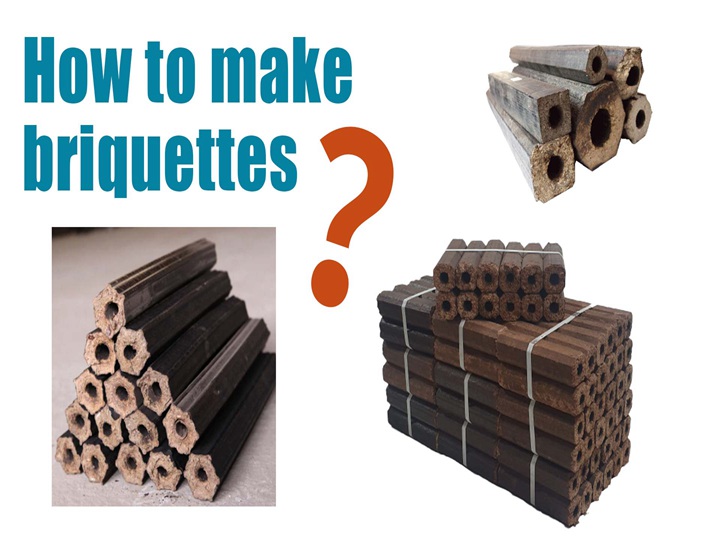

Yığınlar halinde artan testere tozu, odun talaşı veya tarımsal atıklar mıyla mı uğraşıyorsunuz? Maliyetli bertaraf yerine, bu atıkları yüksek talep gören, değerli bir ürüne dönüştürmek ister misiniz? Endüstriyel testere tozu kömürleme makinemiz (aynı zamanda biyokütle kömür presi veya pini kayı ekstrüzyon makinesi olarak da bilinir) en iyi çözümdür. Bol basınç ve ısı kullanarak, gevşek biyokütleyi yoğun, yüksek enerjili yakıt kütüklerine sıkıştırır, işletmeniz için karlı yeni bir fırsat yaratır.

Neden Testere Tozu Kömürleme Makinesi Yatırımı Yapmalısınız? Karlılık Yolunuz

Kömürleme presine yatırım yapmak, sadece bir ekipman almak değil; kârınızı artırmak ve sürdürülebilirliği geliştirmek için stratejik bir adımdır. İşte makinemizin sunduğu olağanüstü değer:

- Yeni Bir Gelir Kaynağı Yaratın: Atıklar için para saçmayı durdurun. Testere talaşı, pirinç kabuğu ve diğer biyokütleleri yüksek yoğunluklu briketlere dönüştürün; bu briketler ısıtma veya endüstriyel kullanım için premium, çevre dostu yakıt olarak satılabilir.

- Maliyetleri Büyük Ölçüde Azaltın: Slash your waste disposal fees and transportation expenses. Our machine can reduce your material volume by up to 90%, freeing up valuable storage space and simplifying logistics.

- Enerji Bağımsızlığı Sağlayın: Dalgalı enerji fiyatlarına karşı koruma. Ürettiğiniz briketleri kendi kazanlarınız veya ısıtma sistemlerinizde yakmak için kullanın, böylece operasyonel enerji maliyetlerinizi önemli ölçüde azaltın. Biliyor muydunuz? Sadece 2kg odun briketi, 1 litre ısıtma yağını yerine geçebilir.

- Güvenliği ve Temizliği Artırın: Geviş getiren, tozlu malzemeleri katı bloklara sıkıştırmak, havadaki tozun yayılmasını büyük ölçüde azaltır, toz patlaması riskini en aza indirir ve daha temiz, daha güvenli bir çalışma ortamı sağlar.

Hangi Ham Maddeler İşlenebilir?

Doğal lignin içeren hemen hemen her biyokütle atığı değerli kömürlere dönüştürülebilir. Anahtar nokta, malzemenin uygun boyutta ve kuru olmasıdır. Makinemiz, şu işlemlerde mükemmeldir:

- Odun Atıkları: Testere artıkları, odun talaşı, odun şıngı, zımpara tozu, kırılmış paletler.

- Tarım Artıkları: Pirincin kabuğu, mısır sapları, ürün sapları, şeker kamışı posası, hindistan cevizi kabukları, yerfıstığı kabukları.

- Orman Atıkları: Çalılık dalları, bambu tozu, ağaç kabuğu.

En iyi sonuçlar için Malzeme Gereksinimleri

- Boyut: En iyi sonuçlar için, hammadde 8mm'den küçük bir boyuta kırılmalıdır (5mm idealdir). Güvenilir bir kırıcı mı arıyorsunuz? Bize göz atın ahşap kırıcı makinesi.

- Nem: Nem içeriği %8 ile arasında kontrol edilmelidir. Malzemeniz çok ıslaksa, verimli talaş kurutucu makinesi hızla briketleme için hazır hale getirilebilir.

Testere Tozu Kömürleme Makinemizin Çalışma Prensibi

Makinemiz, kömür üretimini basit ve verimli hale getirir. Süreç tamamen otomatik olup, az denetim gerektirir. İşte adım adım açıklaması:

- Besleme: Hazırlanan ham malzeme makinenin haznesine beslenir. Bir vida konveyörü, malzemeyi ön dolum odasına iter.

- Isıtma ve Sıkıştırma: Malzeme ana presleme odasına girer, bu oda ısıtıcı halkalarla çevrilidir. Sıcaklık arttıkça (genellikle 280-380°C), biyokütledeki doğal lignin yumuşar. Güçlü bir vida pervanesi sonra büyük bir basınç uygular ve malzemeyi sıkıştırır.

- Şekillendirme: Sıkıştırılmış, ısıtılmış malzeme özel tasarlanmış kalıplama kalıbından geçirilerek yoğun, katı bir briket haline getirilir ve ortasında delik (bu, düzgün yanmayı sağlar) bulunur.

- Soğutma ve Kesme: Tamamlanan briketler makineden çıkar ve sonra soğutulur, istenilen uzunlukta kesilebilir, ambalajlama, satış veya kömüre dönüştürme işlemlerine hazır hale gelir.

İhtiyacınıza Uygun Modeli Seçin

Özel üretim ihtiyaçlarınıza ve bütçenize uygun birkaç model sunuyoruz. İster küçük atölye, ister büyük ölçekli endüstriyel işletme olun, sizin için mükemmel makineyi buluyoruz.

| Model | Kap: (kg/h) | Motor Gücü | Ana Özellikler |

|---|---|---|---|

| SLIII-1 | 160-200 | 15 kW | Küçük ölçekli işletmeler ve yeni başlayanlar için idealdir. Kompakt ve verimlidir. |

| SLIII-2 | 220-260 | 18.5 kW | En popüler modelimiz, çıktı ve güç tüketimi arasında mükemmel denge sağlar. |

| SLIII-3 | 280-320 | 22 kW | Yüksek hacimli endüstriyel üretim ve sürekli 24/7 çalışma için tasarlanmıştır. |

Dayanıklılık için Tasarlanmış Ana Bileşenler

Uptime'nin kritik olduğunu biliyoruz. Bu nedenle, makinemizin her bileşeni yüksek kaliteli, aşınmaya dayanıklı malzemelerle inşa edilmiştir, böylece uzun hizmet ömrü ve minimum bakım sağlar.

Aşınmaya Dayanıklı Vida Pervane

Makinenin kalbi. Yüksek kaliteli alaşımlı çelikten yapılmış ve aşınmaya karşı özel kaplamalı olan pervane ucu, sürekli aşınmaya dayanacak şekilde tasarlanmıştır, böylece tutarlı basınç ve çıktı sağlar.

Yüksek Verimli Isıtma Halkaları

Güçlü ısıtma sistemimiz, hızlı ve stabil sıcaklık kontrolü sağlar, bu da yüksek kaliteli, çatlamayan kömürlerin şekillendirilmesi için çok önemlidir. Kolayca değiştirilebilir tasarımıyla arıza süresi en aza indirilir.

Dayanıklı Şekillendirme Silindiri

Yüksek aşınmaya dayanıklı çelik kompozitten yapılmış olan şekillendirme silindiri (kalıp), aşırı basınç altında bile şeklini ve bütünlüğünü korur, böylece binlerce saatlik kullanımda bile kömür boyut ve yoğunluğunun tutarlı olmasını sağlar.

Müşteri Başarı Hikayeleri

Sadece bizim sözümüze inanmayın. Dünya genelinde işletmelerin ekipmanlarımızla nasıl başarılı olduğunu görün.

Nijerya: Bir müşteri, 3 yıllık kömürcilik deneyimiyle, yerel talebin hızla artmasıyla birlikte, kırıcılar, kurutucular ve çok sayıda kömürleme makinesi dahil olmak üzere tüm operasyonunu tamamlayan üretim hattını yükseltti. Hikayenin tamamını okuyun.

Tanzanya: Bir müşteri, tarımsal atıkları kar etmeye dönüştürmek için pirinç kabuğu kömürleme makinesi satın aldı. Artık yüksek kalorili pini kayı kömürlerini yerel restoranlara, otellere ve hamamlar gibi kazan yakıtı olarak tedarik ediyor. Daha fazla bilgi edinin.

Kömürleme makinesi videosu

Sıkça Sorulan Sorular (SSS)

Soru: Bir testere tozu kömürleme makinesinin yatırım getirisi (ROI) nedir?

Cevap: ROI genellikle çok yüksek ve hızlıdır. Müşterilerimizin çoğu, bertaraf maliyetlerindeki tasarruflar ve kömür satışlarından elde edilen gelir sayesinde 12-18 ay içinde yatırımını geri alır. Size özel ROI hesaplaması yapabiliriz.

Soru: Kömürleme presi dışında başka makineler de gerekiyor mu?

Cevap: Bu, ham maddelerinize bağlıdır. Eğer malzemeniz çok büyük veya çok ıslaksa, bir ahşap kırıcı ve bir kuruş kurutucu gerekebilir. Tüm üretim hattınız için eksiksiz, anahtar teslim çözümler sunabiliriz.

Soru: Bu kömürler kömüre dönüştürülebilir mi?

Cevap: Kesinlikle! Makinemizle üretilen kömürler, yüksek kaliteli mangal veya endüstriyel kömür yapmak için ideal bir giriş malzemesidir. Ayrıca, kokuşmuşlaştırma fırını kullanılarak daha yüksek piyasa değeri olan ürünler elde edilebilir.

Soru: Kurulum ve eğitim sağlıyor musunuz?

Cevap: Evet, kapsamlı destek sunuyoruz. Detaylı kurulum kılavuzları, video rehberleri ve uzaktan teknik destek sağlayarak makinenizin doğru şekilde kurulmasını ve ekibinizin güvenli ve verimli çalışması için eğitilmesini sağlıyoruz. Detaylı operasyon adımları için çevrimiçi kullanım kılavuzumuza başvurabilirsiniz.

Atıklarınızı gelir kaynağına dönüştürmeye hazır mısınız?

İşletmenizin kârını kölelik etmeyin. Bugün uzman ekibimizle iletişime geçin. Size en uygun makineyi seçmenize, tam donanımlı bir üretim hattı kurmanıza ve detaylı, hiçbir yükümlülük içermeyen teklif sunmamıza yardımcı olalım. Daha kârlı ve sürdürülebilir bir gelecek inşa edelim.

Sıcak Ürün

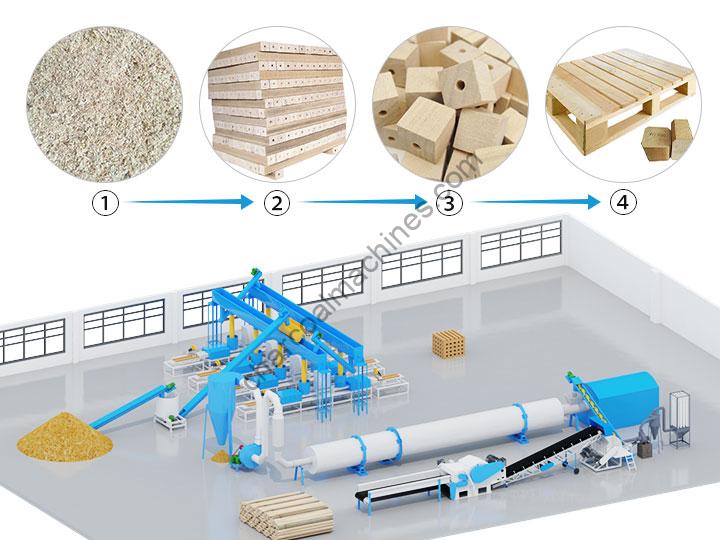

Palet Blokları Yapmak için Ahşap Palet Makinesi

Ticari odun palet blok makineleri,…

Duman Gazı Arıtma Ekipmanları

Duman gazı arıtımı Geçmişte, çünkü…

Shisha (Hookah) Kömürü Üretim Hattı | Pelet Paketleme Kurutucu Tesisi

Otomatik shisha(hookah) kömür üretim hattı şu şekildedir…

Dik Dikey Karbonizasyon Fırını Sert Ahşap Kömürü Üretimi İçin

Hava akışlı taşıma kömürleştirme fırını şu anda…

Ahşap Tozu Öğütücü Makinesi ile Ahşap Unu Yapımı

Ahşap tozu makinesi, ... için kullanılır

Yatay Kömür Fırını Biyokömür Karbonizasyonu İçin

Yatay kömür fırını, yüksek verimli…

Biyokömür Yapımı için Kömür Makinesi ve Üretim Hattı

Kömür yapma makineleri, biyokütle atıklarını…

Kompresli Ahşap Palet blokları yapmak için Ahşap Blok Üretim Hattı

Odun blok üretim hattı yüksek kaliteli sıkıştırılmış…

Tozdan Pini Kay Peletleri Paketlemek için Termal Daralma Paketleme Makinesi

Bu otomatik termal daralma paketleme makinesi…

4 yorum