Machine à briquettes de sciure à haut rendement à vendre

Transformez la sciure, les balles de riz et les déchets de bois en briquettes de combustible précieuses. Notre robuste machine à briquettes de sciure offre un retour sur investissement élevé en réduisant les coûts d'élimination et en créant une nouvelle source de revenus. Obtenez votre devis gratuit dès aujourd'hui !

Machine à briquettes de sciure à haut rendement à vendre

Transformez la sciure, les balles de riz et les déchets de bois en briquettes de combustible précieuses. Notre robuste machine à briquettes de sciure offre un retour sur investissement élevé en réduisant les coûts d'élimination et en créant une nouvelle source de revenus. Obtenez votre devis gratuit dès aujourd'hui !

Caractéristiques principales

Êtes-vous aux prises avec des tas croissants de sciure, de copeaux de bois ou de déchets agricoles ? Au lieu de payer pour une élimination coûteuse, que diriez-vous de transformer ces déchets en un produit précieux et très demandé ? Notre machine industrielle à briquettes de sciure (également connue sous le nom de presse à briquettes de biomasse ou extrudeuse pini kay) est la solution ultime. Elle utilise une pression et une chaleur immenses pour compresser la biomasse lâche en bûches de combustible denses et à haute teneur énergétique, créant ainsi une nouvelle opportunité rentable pour votre entreprise.

Pourquoi investir dans une machine à briquettes de sciure ? Votre chemin vers la rentabilité

Investir dans une presse à briquettes est plus qu'un simple achat d'équipement ; c'est une décision stratégique pour augmenter votre rentabilité et améliorer la durabilité. Voici comment notre machine offre une valeur exceptionnelle :

- Générez une nouvelle source de revenus : Arrêtez de jeter de l'argent dans les déchets. Convertissez la sciure, les balles de riz et d'autres biomasses en briquettes à haute densité qui peuvent être vendues comme combustible de première qualité et écologique pour le chauffage ou l'usage industriel.

- Réduisez considérablement les coûts : Réduisez vos frais d'élimination des déchets et vos dépenses de transport. Notre machine peut réduire le volume de vos matériaux jusqu'à 90 %, libérant ainsi un espace de stockage précieux et simplifiant la logistique.

- Atteignez l'indépendance énergétique : Couvrez-vous contre la volatilité des prix de l'énergie. Utilisez les briquettes que vous produisez pour alimenter vos propres chaudières ou systèmes de chauffage, réduisant ainsi considérablement vos coûts énergétiques opérationnels. Saviez-vous que 2 kg de briquettes de bois peuvent remplacer 1 litre de fioul de chauffage ?

- Améliorez la sécurité et la propreté : La compression de matériaux lâches et poussiéreux en blocs solides réduit considérablement la poussière en suspension dans l'air, minimisant ainsi le risque d'explosions de poussière et créant un environnement de travail plus propre et plus sûr.

Quels matériaux bruts peuvent être traités ?

Pratiquement tous les déchets de biomasse contenant de la lignine naturelle peuvent être transformés en briquettes précieuses. La clé est de s'assurer que le matériau est correctement dimensionné et séché. Notre machine excelle dans le traitement de :

- Déchets de bois : Sciure, copeaux de bois, copeaux de bois, poussière de ponçage, palettes déchiquetées.

- Résidus agricoles : Balles de riz, tiges de maïs, paille de culture, bagasse de canne à sucre, coques de noix de coco, coquilles d'arachide.

- Déchets forestiers : Branches d'arbustes, poudre de bambou, écorce d'arbre.

Exigences relatives aux matériaux pour des résultats optimaux

- Taille :Pour de meilleurs résultats, les matières premières doivent être broyées en morceaux de moins de 8 mm (5 mm étant idéal). Vous avez besoin d’un concasseur fiable ?Découvrez notremachine à concasser le bois.

- Humidité : La teneur en humidité doit être contrôlée entre 8 % et 12 %. Si votre matériau est trop humide, notre efficace séchoir à sciure peut le préparer rapidement pour le briquetage.

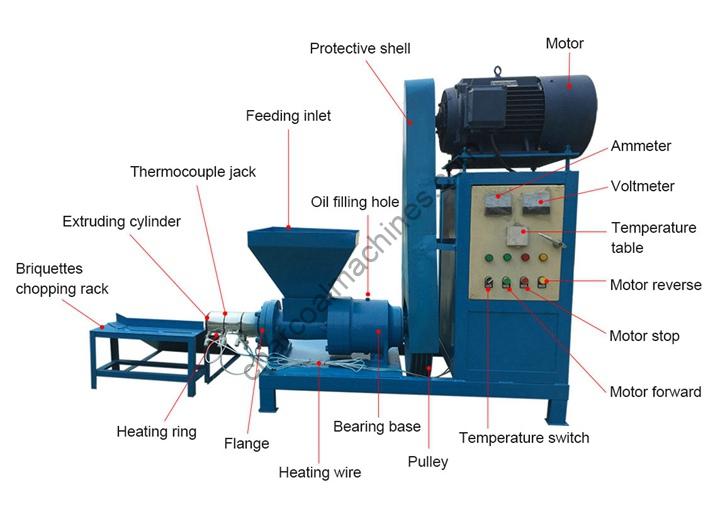

Comment fonctionne notre machine à briquettes de sciure

Notre machine rend la production de briquettes simple et efficace. Le processus est entièrement automatisé et nécessite une surveillance minimale. Voici une description étape par étape :

- Alimentation : La matière première préparée est introduite dans la trémie de la machine. Un convoyeur à vis pousse le matériau dans la chambre de pré-charge.

- Chauffage et compression : Le matériau entre dans la chambre de pressage principale, entourée d'anneaux chauffants. Lorsque la température monte (généralement à 280-380°C), la lignine naturelle de la biomasse ramollit. Une puissante hélice à vis applique ensuite une pression immense, compressant le matériau.

- Mise en forme : Le matériau compressé et chauffé est extrudé à travers une filière de moulage spécialement conçue, le formant en une briquette dense et solide avec un trou central (qui facilite une combustion uniforme).

- Refroidissement et découpe : Les briquettes finies sortent de la machine, sont ensuite refroidies et peuvent être coupées à la longueur désirée, prêtes pour l'emballage, la vente ou un traitement ultérieur en charbon de bois.

Choisissez le bon modèle pour vos besoins

Nous proposons plusieurs modèles pour répondre à vos besoins de production spécifiques et à votre budget. Que vous soyez un petit atelier ou une grande opération industrielle, nous avons la machine parfaite pour vous.

| Modèle | Capacité (kg/h) | Puissance moteur | Caractéristiques principales |

|---|---|---|---|

| SLIII-1 | 160-200 | 15 kW | Idéal pour les opérations à petite échelle et les startups. Compact et efficace. |

| SLIII-2 | 220-260 | 18,5 kW | Notre modèle le plus populaire, offrant un excellent équilibre entre rendement et consommation d'énergie. |

| SLIII-3 | 280-320 | 22 kW | Conçu pour la production industrielle à gros volume et le fonctionnement continu 24h/24 et 7j/7. |

Composants clés : Conçus pour la durabilité

Nous comprenons que le temps de fonctionnement est essentiel. C'est pourquoi chaque composant de notre machine est fabriqué avec des matériaux de haute qualité et résistants à l'usure pour garantir une longue durée de vie et une maintenance minimale.

Hélice à vis résistante à l'usure

Le cœur de la machine. Fabriquée en acier allié de haute qualité et traitée pour une dureté extrême, la pointe de l'hélice est spécialement revêtue pour résister à une abrasion constante, garantissant une pression et un rendement constants.

Anneaux chauffants à haut rendement

Notre système de chauffage robuste assure un contrôle de température rapide et stable, essentiel pour former des briquettes de haute qualité sans fissures. Ils sont conçus pour un remplacement facile afin de minimiser les temps d'arrêt.

Cylindre de mise en forme durable

Fabriqué à partir d'un composite d'acier résistant à l'usure, le cylindre de mise en forme (matrice) conserve sa forme et son intégrité même sous une pression extrême, garantissant une taille et une densité de briquettes uniformes sur des milliers d'heures de fonctionnement.

Histoires de réussite de clients

Ne vous contentez pas de nous croire sur parole. Voyez comment les entreprises du monde entier réussissent avec nos équipements.

Nigeria : Un client ayant 3 ans d'expérience dans le secteur du charbon de bois a modernisé toute son exploitation avec notre chaîne de production complète, comprenant des broyeurs, des séchoirs et plusieurs machines à briquettes, pour répondre à la demande locale croissante. Lisez l'histoire complète.

Tanzanie : Un client a acheté notre machine à briquettes de balles de riz pour transformer les déchets agricoles en profit. Il fournit maintenant des briquettes pini kay à haut pouvoir calorifique aux restaurants locaux, hôtels et maisons de bains comme combustible de chaudière. En savoir plus.

Vidéo de la machine à fabriquer des briquettes

Questions Fréquemment Posées (FAQ)

Q : Quel est le retour sur investissement (ROI) d'une machine à briquettes de sciure ?

R : Le ROI est généralement très élevé et rapide. Bon nombre de nos clients constatent un retour sur leur investissement dans les 12 à 18 mois, grâce aux économies sur les coûts d'élimination et aux revenus des ventes de briquettes. Nous pouvons vous aider à calculer un ROI précis en fonction de votre situation spécifique.

Q : Ai-je besoin d'autres machines que la presse à briquettes ?

R : Cela dépend de votre matière première. Si votre matériau est trop gros ou trop humide, vous aurez besoin d'un broyeur à bois et d'un séchoir à sciure. Nous pouvons fournir une solution complète et clé en main pour toute votre ligne de production.

Q : Ces briquettes peuvent-elles être transformées en charbon de bois ?

R : Absolument ! Les briquettes produites par notre machine sont la matière première idéale pour fabriquer du charbon de bois BBQ ou industriel de haute qualité. Elles peuvent être carbonisées dans notre four de carbonisation continue pour créer un produit à valeur marchande encore plus élevée.

Q : Fournissez-vous l’installation et la formation ?

R : Oui, nous offrons un support complet. Nous proposons des manuels d’installation détaillés, des guides vidéo et une assistance technique à distance pour garantir que votre machine est correctement installée et que votre équipe est formée pour une utilisation sûre et efficace. Pour les étapes opérationnelles détaillées, vous pouvez consulter notremanuel d’utilisation en ligne.

Prêt à transformer vos déchets en une source de revenus ?

Arrêtez de laisser les déchets gruger vos profits. Contactez notre équipe d'experts dès aujourd'hui. Nous vous aiderons à choisir la machine parfaite, à configurer une ligne de production complète et à vous fournir un devis détaillé et sans engagement. Construisons ensemble un avenir plus rentable et plus durable pour votre entreprise.

Produit populaire

Machine industrielle à granulés de bois à vendre

La machine à granulés de bois fait référence à la compression...

Machine à briquettes de sciure à haut rendement à vendre

La machine industrielle à briquettes de sciure est principalement utilisée pour...

Four de carbonisation verticale pour la production de charbon de bois dur

Le four de carbonisation à levage d'air est actuellement le...

Équipement de purification des gaz de combustion

Purification des gaz de combustion Dans le passé, en raison de...

Machine de broyage de charbon de bois pour fabriquer de la poudre de charbon de bois fine

La machine de broyage de charbon de bois, également connue sous le nom de...

Machine à briquettes de charbon en nid d'abeille

La machine à briquettes de charbon en nid d'abeille peut presser la poudre de charbon pulvérisée...

Séchoir continu pour le séchage de la sciure et des balles de riz

Industrial sawdust dryers and rice husk drying machines…

Machine à copeaux de bois pour litière animale

La machine à copeaux de bois peut traiter des rondins et…

Broyeur de bois à tambour pour la production massive de plaquettes de bois

La machine broyeur déchiqueteuse à copeaux de bois peut principalement être...

4 commentaires