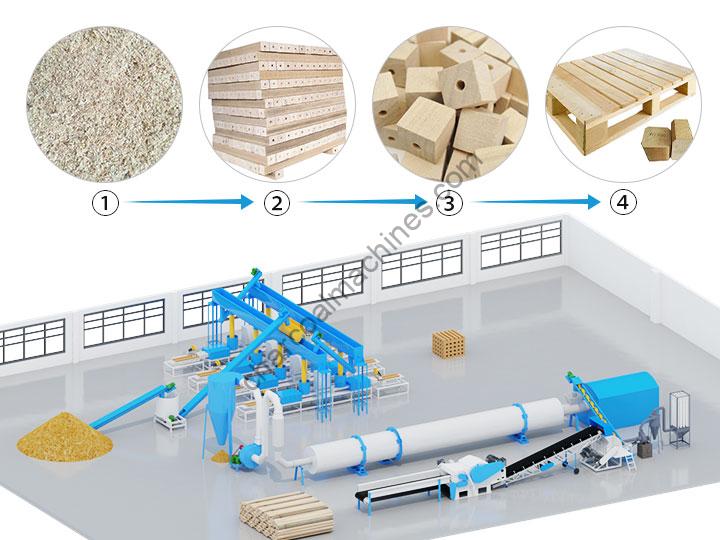

Commercial wood pallet block making machines can extrude biomass raw materials such as sawdust and wood shavings into solid blocks under high temperature and high pressure conditions. The finished wood blocks can be cut and used to make the feet of wooden pallets. The production process of wood pallet blocks using sawdust block machine mainly includes sawdust drying, sawdust blocks extruding, compressed blocks cutting, and so on. The size and length of the wood blocks can be customized according to customer needs.

Raw materials for making compressed wood pallet blocks

There are many raw materials for processing wood blocks, and almost all biomass chips can be used for production. The most common processing raw materials are sawdust and wood shavings, coconut fiber, straw scraps, etc.

Main features required for raw materials

Material size: less than 5 mm. We can use the wood shredder to shred all kinds of biomass waste, such as branches, wood scraps, tree roots, logs, waste wood boards, etc., into sawdust and wood shavings with a size of 3-5mm.

Matrial humidity: less than 10%. The humidity of raw materials such as sawdust and wood shavings should not exceed 10%. If the humidity of the raw material is too high, the quality of the finished product will be poor, and the processing efficiency will be very low. We can use the おがくず乾燥機 to continuously dry the raw materials and quickly reduce the moisture content of the raw materials.

Wood pallet block making machine for sale

Wood pallet block making machine has a set of left and right symmetrical extrusion devices. The main structure of the machine includes feeding port, frame, heating plate, hydraulic cylinder, extrusion die, etc.

When the sawdust pallet block machine is working, its internal hydraulic device will push the sawdust entering from the feeding port to move forward. When the sawdust is pushed into the heating zone of the machine, the lignin in the sawdust and other biomass feedstocks is thermally decomposed and fully bonded to the molecules in the feedstock.

Therefore, sawdust blocks processed by wood pallet block making machine usually have smooth surface, high density and hardness, very wear-resistant and strong load-bearing capacity.

How doese the sawdust block machine work?

Why is glue mixed in the raw materials for making wood blocks?

Before processing wood pallet blocks, we usually put sawdust into a mixer and mix with a certain proportion of glue, why is this? In fact, this added glue is called urea-formaldehyde resin glue, which is a safe and non-toxic thermosetting polymer adhesive.

The glue is made from formaldehyde, urea, polyvinyl alcohol, melamine, ammonia, and alkalis and acids for pH adjustment. The purpose of adding glue is to increase the viscosity between sawdust, so that the processed wood blocks have better density and hardness.

Parameters of wood pallet block making machine

| モデル | Power | 容量 | Dimension | Weight |

| SL-75/2 | 15KW | 3.5m³/d | 75*75*1200mm | 1500kg |

| SL-90/2 | 15KW | 4m³/d | 90*90*1200mm | 1800kg |

| SL-100/2 | 18KW | 5m³/d | 100*100*1200mm | 2000kg |

| SL-120 | 15KW | 3.5m³/d | 100*120*1200mm | 1500kg |

| SL-145 | 18KW | 3.5m³/d | 145*145*1200mm | 1800kg |

人気商品

バイオ炭を作る最新の製炭機

The newest charcoal making machine is the ideal…

バイオマスペレット燃料製造用木質ペレット機

Wood pellet machine refers to the compression of…

バイオ炭を作るための木炭機と生産ライン

The charcoal making machines can turn biomass wastes,…

圧縮木製パレット生産ライン

圧縮木製パレットの生産ラインは…

水ギセル シーシャ炭生産ライン |丸型・立方体練炭づくり

The shisha hookah charcoal production line is designed…

広葉樹木炭製造用縦型炭化炉

気流昇降式炭化炉は現在…

木材チップ量産用ドラムウッドチッパー

ウッドチッパーシュレッダーマシンは主に…

動物の寝具用木材シェービングマシン

木材削り機は丸太を加工して…

バイオマス木質ペレット生産ライン

The biomass wood pellet production line is an…

2件のコメント