インドネシア向け20台の木炭圧縮機

シュリー工場は先週末にインドネシアへ20セットの木炭圧縮機と完全な予備部品、圧縮金型を再び出荷しました。これらの木炭圧縮機は、インドネシアの新たに開設された木炭加工工場で、人気の四角形と六角形の木炭を加工するために使用されます。これはこのイラクのお客様が当工場と協力するのは2回目であり、今後もより多くの協力の機会があることを願っています。

なぜ再びShuliyを選ぶのか?

イラクのお客様は、インドネシアで5年以上木炭生産事業を運営しています。2019年に、非常に信頼できる中国の仲介者に木炭加工設備の購入を委託しました。彼の仲介者は中国の複数の木炭設備メーカーを選定し、最終的に当工場から容量500kg/hの木炭圧縮機3台を注文しました。

機械の良い経験から、イラクのお客様は昨年11月に仲介者に委託して、当工場との新しい注文を交渉させました。イラクのお客様は、新しい木炭工場を始めたいと考えており、主に四角形と六角形の木炭を加工したいと述べました。

炭のブリケット製造機の新しい要件

イラクのお客様は、前回の注文と同じタイプの木炭圧縮機10台を、出力500kg/hで注文しました。ただし、自己使用のため、木炭圧縮機に半メートルの棚を追加したり、2台の機械を一緒に動作させることでスペースを節約したりする新しいカスタマイズ要件を私たちに提示しました。

さらに、大きな生産ニーズに対応するため、お客様は容量1000kg/hの大型木炭圧縮機をもう10台注文しました。

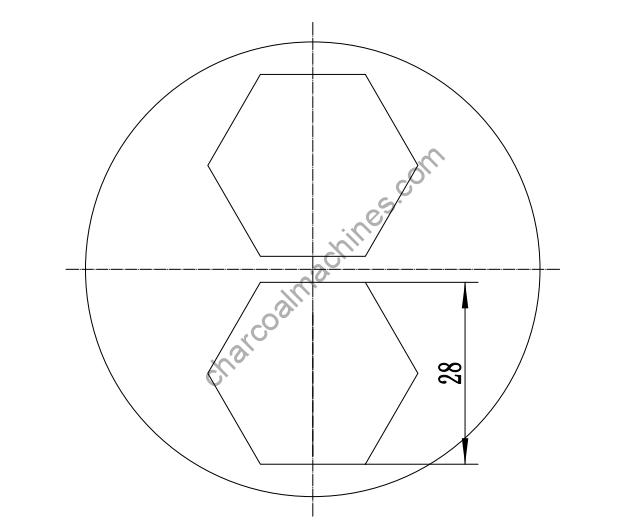

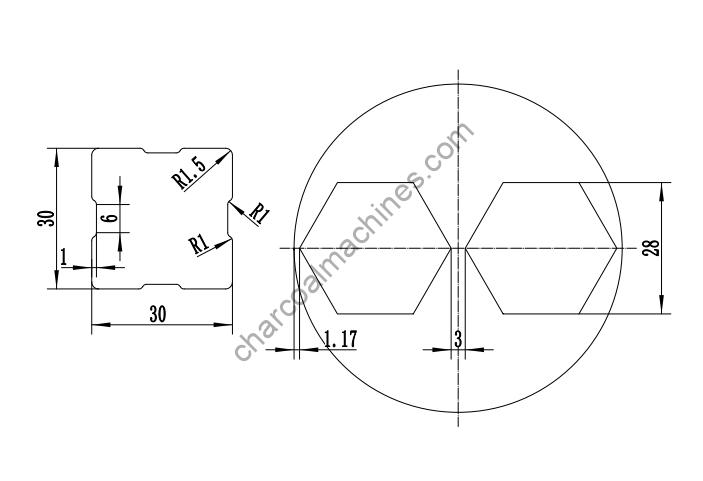

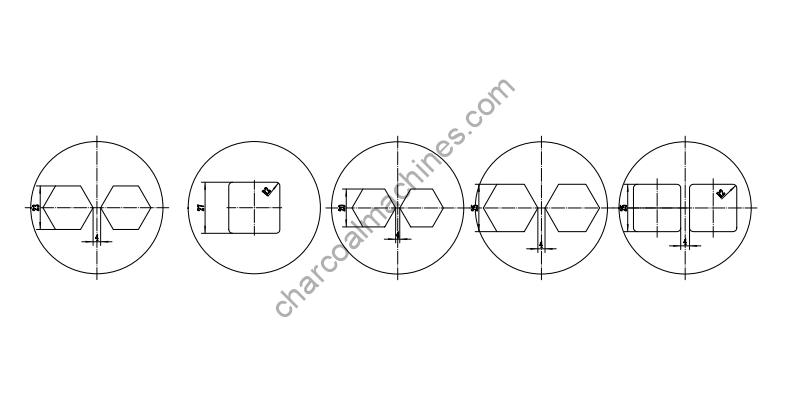

お客様は、処理したい木炭のサイズと形状も教えてくれ、エンジニアはお客様から提供されたデータに基づいて金型を厳密にカスタマイズしました。

完成したブリケット押出機と金型の展示

当工場は通常多くの注文を抱えているため、一定の在庫を持っています。今回イラクのお客様が注文した2種類の木炭押出し機はすべて在庫にあります。

お客様のさまざまなニーズを確認した後、すぐに配送の手配を開始しました。ただし、このお客様が必要とする押出し金型はすべてカスタマイズ版であり、当工場はお客様が必要とする金型を最短時間で加工しました。

インドネシアの炭ブリケット工場の注文リスト

今回のインドネシア向け注文には、主に20台の木炭圧縮機、3台の木炭粉砕用ハンマーミル、4台のホイールグラインダー、および5つのコンベヤーが含まれます。その他は金型やねじなどの機械付属品です。お客様が必要とする商品数が多いため、4つの40フィートコンテナにて手配しました。

| 品番 | 名前 | 数量 |

| 1 | モデル140の木炭圧縮機 | 10 |

| 2 | モデル140のねじ | 10 |

| 3 | モデル140の金型(直径2cmの六角穴が二つ) | 10 |

| 4 | モデル140の金型(直径2.5cmのキューブ穴が二つ) | 10 |

| 5 | モデル140の金型(六角穴が二つ。直径は2.5cm。) | 10 |

| 6 | モデル140の金型(直径2.8cmの二つの六角穴が二つ) | 6 |

| 7 | モデル140の金型(直径3cmのキューブ穴が一つ) | 6 |

| 8 | モデル140の金型(キューブ穴が一つ。穴のサイズは2.7cm。) | 10 |

| 9 | モデル140の金型(六角穴が二つ。穴のサイズは2.3cm。) | 10 |

| 10 | アイアン棚 | 2 |

| 11 | アイアン棚 | 3 |

| 12 | モデル180の木炭圧縮機(金型なし) | 5 |

| 13 | モデル180の木炭圧縮機 (高さを高くし、金型なし) | 5 |

| 14 | モデル180のねじ | 10 |

| 15 | ハンマーミル | 3 |

| 16 | ブレンダー | 4 |

| 17 | ホブコンベヤ(ブレード間隔:5cm) | 2 |

| 18 | ホブコンベヤ(ブレード間隔:2.7cm) | 2 |

| 19 | ホブコンベヤ(ブレード間隔:2.5cm) | 1 |

| 20 | モデル140のねじ | 2 |

| 21 | モデル140の最初のセクションのねじ | 2 |

| 22 | モデル180のねじ | 2 |

| 23 | モデル180の最初のセクションのねじ | 2 |

| 24 | ハンマーミルのスクリーン(穴のサイズは3mm) | 10 |

コメントなし