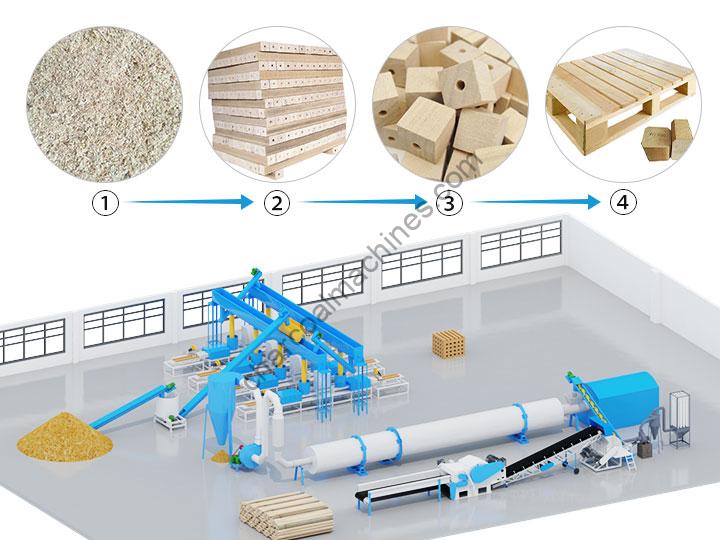

木块生产线可以加工高质量的压缩锯末块,用于木托盘加工。压缩木块生产线的主要工艺包括木材粉碎、锯末干燥、锯末混合、木块挤出成型、木块切割等。

使用锯末块机,我们可以回收大量锯末、木屑和各种生物质原料,生产高附加值的木块。目前,许多国外客户已订购我们的全套木块制造设备,用于托盘加工业务,如美国、墨西哥、阿根廷、马来西亚、新西兰、加纳、南非、伊朗、沙特阿拉伯、罗马尼亚、德国、比利时、芬兰、俄罗斯等。

什么是木托盘块?

木托盘块是在高温高压条件下压制而成的木块。由于木块是在巨大压力下制造的,其密度和硬度都很高,不易变形和被潮气磨损,使用寿命长。

此类木块常用于进一步组装成木质托盘,作为木托盘的支撑角。不同规格的木托盘所需木块数量不同。此外,木块还用于加工各种木制工艺品、积木、家具等。

用来制造压缩托盘块的原料有哪些?

用于生产压缩块的原料丰富且价格低廉,如锯末、稻壳、木屑、树枝、根部、木废料、稻草、椰纤维、废旧木家具、废旧木托盘、废旧木板等。

在加工木块之前,我们需要使用破碎机将这些原料粉碎成小于5mm的锯末。此外,如果锯末的含水量较高,还需要使用锯末干燥机进行干燥,以使水分含量不超过15%。

完整的木块生产线组成部分

无论是小型托盘块加工厂还是大型木托盘厂,所需的设备基本相同,但所需设备的产量不同。完整的木块生产线通常包括滚筒木片机、锤片机、连续锯末干燥机、锯末搅拌机,以及一个或多个木块挤出机(根据客户的加工产量),以及一个或多个木块切割机。

制木块的机器清单

滚筒木片机

此连续木片机可以快速切割大尺寸的原木、树枝、木屑、废旧木板等成木屑或碎片。其特点是破碎效率高、产量大、操作简单。该滚筒木片机的产量一般在1吨/小时到5吨/小时之间。

木屑破碎机

此锤片机可以快速将滚筒破碎机处理的木屑粉碎成锯末。粉碎机利用锤片高速运转时的冲击原理,将锯末、稻草等粉碎成非常细的锯末。其特点是产量大、无粉尘污染。粉碎机配备除尘装置,可以收集锯末,避免粉尘污染。

锯末干燥机

滚筒干燥机连续干燥含水量高的锯末和稻壳。此连续干燥机的热源可以是煤炭、炭、 biomass颗粒、木材等。锯末干燥机配备除尘装置,可以收集干燥后的锯末,避免烟尘和粉尘污染。

锯末胶水搅拌机

我们使用此自动搅拌机根据一定比例将锯末和尿素甲醛树脂胶均匀混合。然后将混合好的锯末放入托盘块成型机进行挤压。

锯末块挤出机

这种木块机通常由两套对称的挤出装置组成,能从两个出口分别挤出锯末,制造密度更高的木块。机器的动力为电动机,喂料可以通过螺旋输送机自动喂入或手动喂入。机器出口的成型模可以更换,以加工不同尺寸的托盘块。

木块切割机

在托盘块压机的出料口,我们可以安装匹配的木块切割机。此自动切割机由红外传感器控制,能自动感应设定的切割长度并进行切割。

可选的独立木块切割机

为了进一步切割木块,我们可以使用CNC托盘块切割机将长木块切割成相同尺寸的立方体。当然,切割尺寸可以根据需要设置。

舒利木块生产线的主要特点

- 舒利工厂可以根据客户的生产需求和投资预算,提供具有成本效益的压缩托盘块加工解决方案。该木块生产线的成品尺寸和产量可以定制。

- 我们的工厂支持客户实地参观工厂并亲自测试木托盘块设备。此外,对于无法参观工厂的客户,我们也支持线上工厂参观,即通过视频通话和工厂直播,满足客户对机器的了解。

- 我们的工厂工程师可以根据客户的工厂面积、位置和形状等因素,为客户设计设备安装图纸。也可以对设备的电压进行修改。需要的客户,我们可以派工程师到客户国家指导木块机的安装和操作。

木块生产线客户案例

在过去的五年中,我们舒利工厂的压缩木块制造机已在40多个国家和地区安装使用。去年,我们的托盘块工厂主要出口到墨西哥、美国、巴西、印度尼西亚、澳大利亚、索马里、加纳、希腊、罗马尼亚、沙特阿拉伯等国家。

热销产品

炭块包装机,用于定量包装烧烤炭

此定量炭料压块包装机可以…

性能良好的批量炭烘干机

炭烘干机主要用于…

小型饲料颗粒机,用于制作动物饲料

小型饲料颗粒机是家庭的…

垂直碳化炉,用于硬木炭生产

气流提升碳化炉目前是…

压缩木托盘生产线

压缩木质托盘生产线是一个…

炭粉研磨机,用于制作细炭粉

块状木炭研磨机,也称为…

木屑煤块生产线 | Pini Kay热木料厂

木屑压块生产线主要挤压…

炭煤破碎机 | 炭粉研磨机

木炭粉碎机主要可以粉碎各种…

圆形和枕形烧烤炭球压制机

烧烤木炭压制机可以制造压缩木炭…

3条评论