Pengering Kontinu untuk Mengeringkan Serbuk Kayu & Sekam Padi

Pengering Serbuk Kayu | Pengering Sekam Beras

Pengering Kontinu untuk Mengeringkan Serbuk Kayu & Sekam Padi

Pengering Serbuk Kayu | Pengering Sekam Beras

Fitur Sekilas

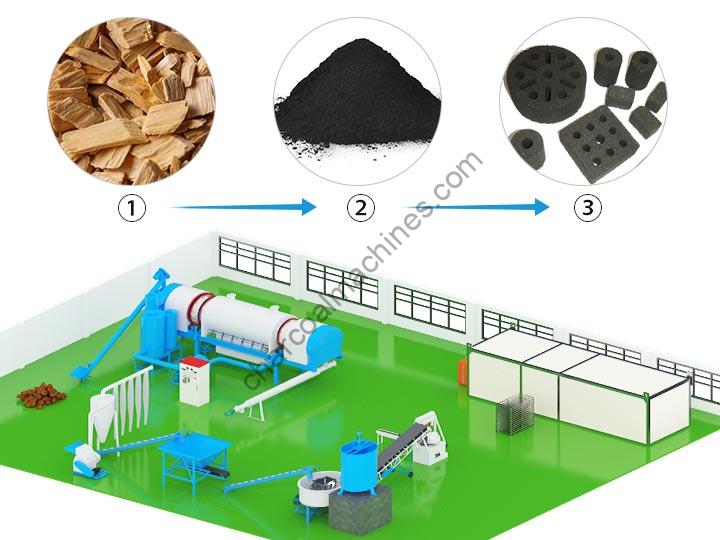

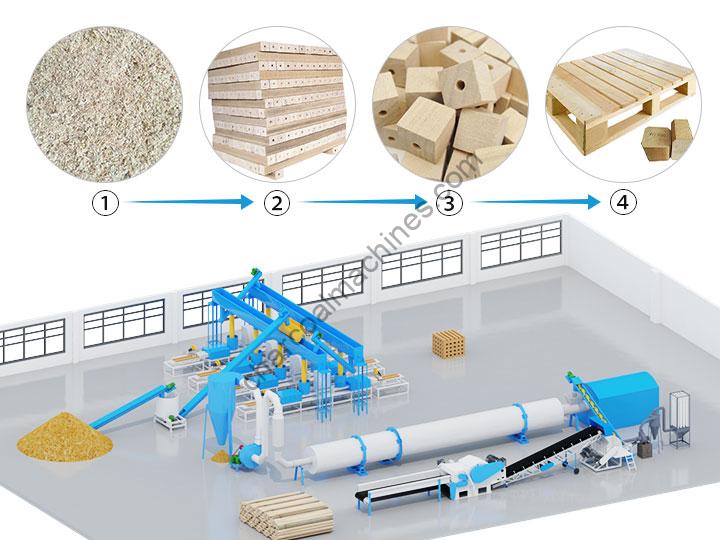

Pengering serbuk kayu industri dan mesin pengering serutan padi utama mencakup pengering aliran udara dan pengering drum. Mesin pengering serbuk kayu dapat mengering serbuk kayu, sekam beras, serpihan kayu, potongan jerami, dll dengan kadar air kurang dari 60% sehingga kadar air menjadi kurang dari 10%. Serbuk kayu kering dan sekam beras dapat digunakan untuk memproses briket serbuk kayu, pini-kay, pelet kayu, papan kayu, kertas, furnitur, dll.

Sumber panas untuk mengering serbuk kayu dan sekam beras terutama menggunakan panas bahan bakar bio. Panas dapat didaur ulang selama proses pengeringan, yang sangat hemat energi. Karena efisiensi pengeringannya yang tinggi, mesin pengering serbuk kayu komersial ini sering digunakan dalam berbagai lini produksi arang dan pabrik kertas.

Klasifikasi mesin pengering serbuk kayu & sekam padi

Saat ini peralatan pengering yang digunakan untuk mengering serbuk kayu dan sekam beras terutama adalah pengering serbuk kayu aliran udara dan pengering serbuk kayu drum. Penampilan, struktur, prinsip kerja, kapasitas pemrosesan, dan skenario aplikasi kedua mesin pengering otomatis ini sangat berbeda.

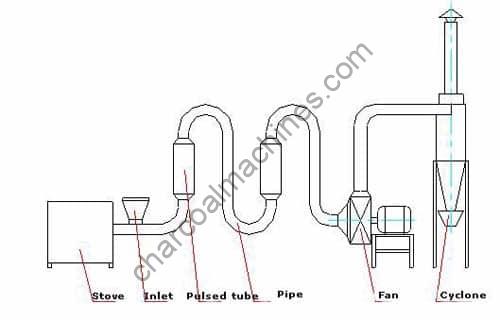

Mesin pengering sekam padi aliran udara

Mesin pengering sekam beras aliran udara juga disebut mesin pengering tipe pipa, yang merupakan peralatan pengering ideal dengan investasi kecil dan keuntungan cepat. Mesin pengering sekam beras aliran udara ini adalah peralatan pengering kontinu dan cepat yang biasanya digunakan dalam lini produksi arang.

Bahan granular yang longgar akan tergantung di udara panas, dan melalui penghilangan kelembapan instan dalam proses pengeringan. Mesin pengering aliran udara ini cocok untuk mengering bahan granular seperti serbuk kayu dan sekam beras. Setelah pengeringan, kadar air bahan baku akan kurang dari 10%.

Proses kerja mesin pengering serpahan serutan kayu dengan aliran udara

Kayu, cabang, balok, bambu, jerami, bagasse tebu, dan bahan biomassa lainnya harus dihancurkan menjadi serbuk kayu oleh mesin pemecah kayu sebelum dikeringkan. Persyaratan bahan baku untuk pengeringan padapengering serbuk aliran udara adalah diameter kurang dari 5mm.

Di depan pengering aliran udara, akan ada kompor nyala untuk menyediakan udara panas seperti pada mesin pengering putar. Setelah serbuk kayu atau sekam beras ditambahkan ke pengering, ia akan terjulur di dalam pipa dengan dorongan kipas. Bahan tersebar merata dalam mesin pengering dan dalam kontak penuh dengan udara panas untuk mempercepat laju pengeringan.

Dalam proses pengeringan, di bawah aksi gas panas, material dibuang dari penangkap debu di ujung pengering setelah pengeringan. Udara panas suhu tinggi dalam mesin pengering aliran udara dalam tabung pengering dengan kecepatan tinggi, waktu tinggal sangat terbatas, sehingga umumnya hanya cocok untuk proses pengeringan penguapan permukaan bahan dengan kecepatan konstan.

Prinsip kerja mesin pengering serbuk kayu aliran udara adalah memasukkan material basah berbutir ke aliran udara panas dan mendapatkan produk bekas kering berbutir. Pengering sekam beras aliran udara memiliki efek baik dalam mengurangi polusi lingkungan.

Aplikasi pengering aliran udara untuk pengeringan serpah serutan kayu

Mesin pengering aliran udara banyak digunakan dalam logam, bahan bangunan, pakan, pertambangan, makanan, obat, kimia, farmasi, pencucian batubara, pembuatan pupuk, industri ringan, dan produksi arang industri.

Output mesin pengering sekam beras berbeda tergantung kadar air bahan baku, berkisar antara 200kg/jh hingga 600kg/jh. Semakin rendah kadar air material, semakin besar output pengering.

Dalam rangkaian produksi arang, mesin pengering udara terutama digunakan di belakang mesin penghancur setelah material dihancurkan, material basah berbutir cepat dikeringkan menjadi produk kering berbutir yang diperlukan. Setelah itu, material diangkut oleh mesin pemberi umpan sekrup ke mesin briket serbuk kayu dan tungku karbonisasi, untuk produksi arang lebih lanjut.

Fitur-fitur mesin pengering serpahan serutan sawah blaba? (terjemahan asli tidak jelas)

- Pengeringan bahan baku: sekam padi, serutan kayu, serpihan, cabang, serpih kayu, dan bahan baku berbentuk granular lainnya setelah digiling (Diameter kurang dari 3 mm, panjang kurang dari 5 mm).

- Produktivitas: udara panas 180 ℃, kelembapan relatif 35% dari serbuk kayu atau sekam beras mengering hingga kelembapan relatif 10%, suhu udara panas tidak kurang dari 180 ℃, suhu mulut keluaran 40-50 ℃.

- Opsi bahan bakar: serutan kayu, cabang, batu bara, uap, atau pemanasan listrik.

- Intensitas pengeringan yang tinggi dan investasi peralatan rendah. Mesin pengering aliran udara dengan kapasitas pengolahan besar, kemampuan penguapan air, berukuran kecil dan investasi lebih sedikit, tidak tertandingi dibandingkan mesin pengering lainnya.

- Tingkat otomatisasi yang tinggi dan kualitas produk yang baik. Selama proses pengeringan, material sepenuhnya diproses di dalam pipa, waktu pengeringan sangat singkat (hanya 2-10 detik). Selama periode ini, panas terutama digunakan untuk penguapan air, dan suhu material itu sendiri tidak banyak naik, sehingga suhu tidak banyak mempengaruhi produk. Oleh karena itu, produk tidak bersentuhan dengan dunia luar, dapat sedikit polusi dan berkualitas baik.

- Pasokan peralatan lengkap dan yang merupakan bagian dari sumber panas opsional. Pengguna dapat mengonfigurasi peralatan yang sesuai berdasarkan kondisi material dan persyaratan proses.

- Mengenai pemilihan mode pemanasan, karena fleksibilitas besar mesin pengering aliran udara, pengguna dapat memilih pemanasan listrik, pemanasan uap, pemanasan minyak konduksi panas, kompor api panas pembakaran batu bara, kompor api gas, pemanasan uap listrik, dan bentuk gabungan lainnya sesuai dengan lokasi peralatan.

Parameter teknis dari mesin pengering serutan kayu aliran udara

| Model | Daya motor | Output | Berat | Pakan diameter | Dimensi |

| 350 | 7.5kw | 180-300kg/jh | 1.5T | ≤5mm | 15.0*2.6*3.8m |

| 400 | 15kw | 700-900kg/jh | 2.5T | ≤5mm | 16.0*2.6*4.0m |

Video mesin pengering serpahan sawit padi beras

Fitur mesin pengering aliran udara

- Pengeringan bahan baku: sekam padi, serutan kayu, serpihan, cabang, serpih kayu, dan bahan baku berbentuk granular lainnya setelah digiling (Diameter kurang dari 3 mm, panjang kurang dari 5 mm).

- Produksi efisiensi: udara panas 180 ℃, kelembapan relatif 35% serpahan kayu atau sekam padi kering hingga kelembapan relatif 10%, suhu udara panas tidak kurang dari 180 ℃, suhu mulut pembuangan 40-50 ℃.

- Opsi bahan bakar: kayu (wood), batu bara, uap, atau pemanasan listrik.

- Intensitas pengeringan yang tinggi dan investasi peralatan rendah. Mesin pengering aliran udara dengan kapasitas pengolahan besar, kemampuan penguapan air, berukuran kecil dan investasi lebih sedikit, tidak tertandingi dibandingkan mesin pengering lainnya.

- Tingkat otomatisasi yang tinggi dan kualitas produk yang baik. Selama proses pengeringan, material sepenuhnya berjalan di dalam pipa, dan waktu pengeringan sangat singkat (hanya 2-10 detik). Selama periode ini, panas terutama digunakan untuk penguapan air, dan suhu material tidak meningkat banyak, sehingga suhu tidak banyak berpengaruh pada produk. Oleh karena itu, produk tidak bersentuhan dengan dunia luar, bisa polusi kecil dan kualitas baik.

- Pasokan peralatan lengkap dan a sumber panas opsional. Pengguna dapat mengonfigurasi peralatan yang sesuai berdasarkan kondisi material dan persyaratan proses.

- Mengenai pemilihan mode pemanasan, karena fleksibilitas besar mesin pengering aliran udara, pengguna dapat memilih pemanasan listrik, pemanasan uap, pemanasan minyak konduksi panas, kompor api panas pembakaran batu bara, kompor api gas, pemanasan uap listrik, dan bentuk gabungan lainnya sesuai dengan kondisi lokasi peralatan.

- Mesin pengering aliran udara dasar cocok untuk bahan granular longgar dan memiliki viskositas rendah, bahan dengan viskositas besar perlu dilengkapi dengan perangkat terkait lainnya.

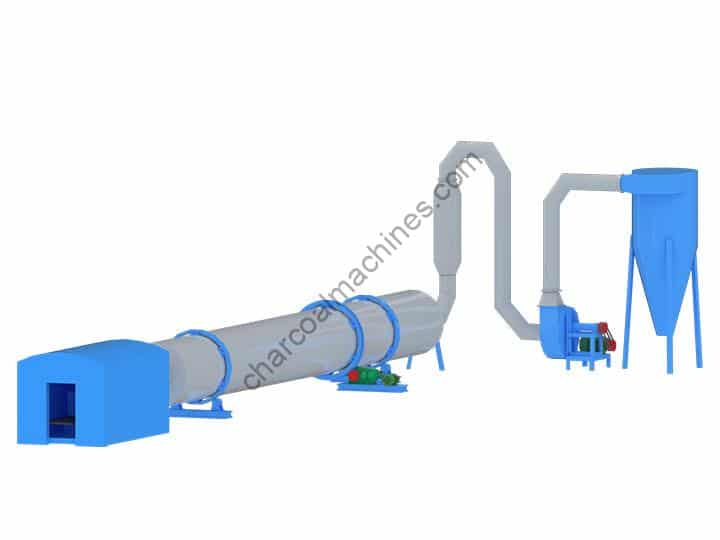

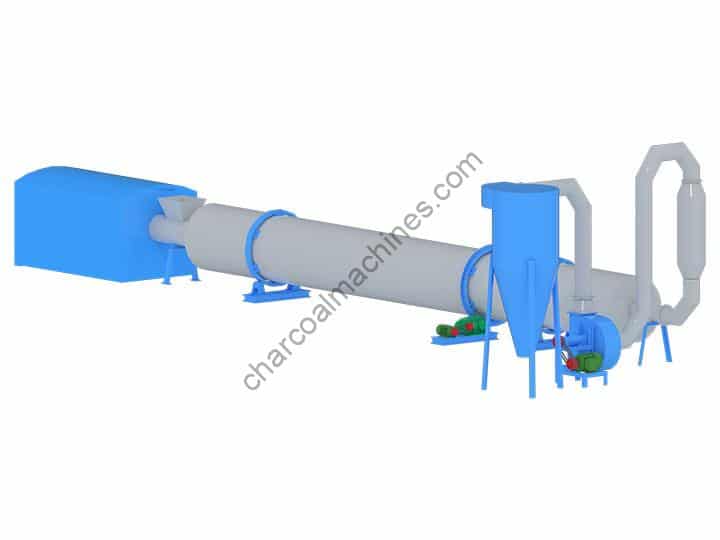

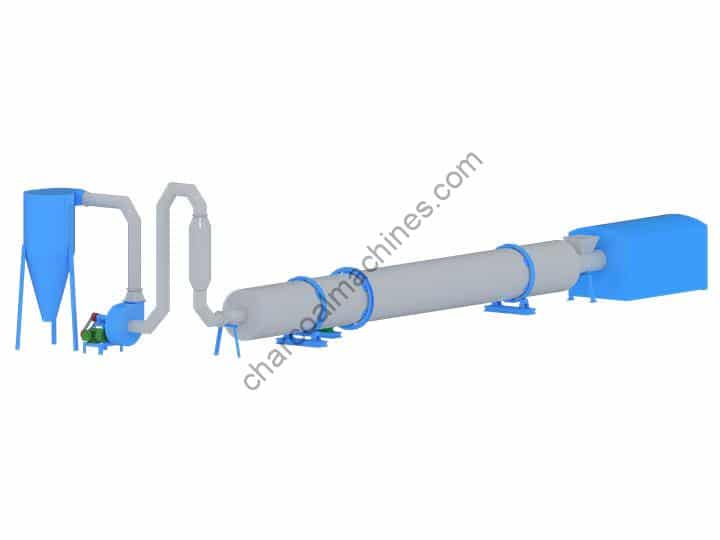

Mesin pengering serbuk kayu drum rotary

Mesin pengering serbuk kayu berputar juga dapat disebut pengering drum dan pengering putar, yang merupakan peralatan pengering umum untuk pemrosesan mineral dan produksi arang.

mesin pengering putar memiliki susunan kompak yang terutama terdiri dari badan berputar, pelat pengangkat, gear, sistem transmisi, perangkat pendukung, cincin penyegel, dan komponen lainnya.

Saat menggunakan mesin pengering ini, kita biasanya harus membangun atau membeli kompor nyala kecil di depan badan drum untuk menyediakan udara panas. Mesin pengering serbuk kayu drum banyak digunakan di industri makanan, pakan hewan, kimia, kedokteran, pertambangan, dan industri lainnya.

Apa itu mesin pengering putar?

Mesin pengering drum sekam padi terlihat seperti silinder yang sedikit miring ke arah horizontal. Bahan berbutir seperti serbuk kayu atau sekam padi ditambahkan dari ujung atas, kemudian udara panas dan bahan mengalir ke tengah silinder. Dengan putaran silinder itu sendiri, bahan bergerak ke ujung bawah dengan bantuan pelat angkat karena pengaruh gravitasi.

Dinding dalam silinder dilengkapi dengan banyak pelat angkat, yang dapat mengangkat dan menyemprotkan bahan, serta meningkatkan permukaan kontak antara bahan dan aliran udara panas, sehingga meningkatkan laju pengeringan dan mendorong bahan bergerak maju. Setelah pengeringan, bahan dikumpulkan dari kolektor debu di bagian bawah mesin pengering rotary.

Bahan baku untuk pengeringan dengan mesin pengering serpahan kayu berbentuk drum

Serbuk kayu, sekam padi, potongan bambu, kulit kacang tanah, potongan kelapa, batang wijen, batang kapas, batang kedelai, slag vinasse, pakan ternak, dan bahan mineral seperti batu kapur slag, bubuk batu bara, slag, tanah liat, dan bahan lainnya.

Pengering putar kapasitas kerja per jam berkisar: 300kg/jh-2000 kg/jh.

Aplikasi mesin pengering serutan kayu berbentuk drum

Output mesin pengering drum berbeda tergantung kelembapan material. Semakin rendah kelembapan material, semakin besar output mesin pengering mesin pengering. Diameter drum berputar bisa berbeda dan bisa kami sesuaikan untuk Anda. Selain itu, kecepatan putaran drum bisa diatur.

Mesin pengering sekam beras ini umum digunakan dalam lini produksi arang untuk mengering bahan pada langkah pertama, kemudian bahan yang biasanya memiliki kadar air kurang dari 10% akan diekstruksi oleh mesin briket serbuk kayu untuk membuat pini-kay. Dan pini-kay dapat di-karbonisasi lebih lanjut oleh tungku karbonisasi.

Mesin pengering serpahan kayu berputar di pabrik

Keuntungan mesin pengering drum industri

- Mesin pengering rotary memiliki kapasitas pengolahan besar, konsumsi bahan bakar lebih sedikit, dan biaya pengeringan rendah.

- The drum mesin pengering mengadopsi struktur tugboat tengah yang dapat disesuaikan, cocok dengan cincin gulung dan secara signifikan mengurangi gesekan serta konsumsi daya.

- The sekam padi mesin pengering dirancang khusus untuk mengatasi struktur roda terblokir, secara signifikan mengurangi dorongan horizontal akibat kemiringan peralatan. Ketahanan beban berlebih yang kuat, tabung berjalan mulus, keandalan tinggi.

- The peralatan pengering serutan kayu memiliki kelebihannya tahan suhu tinggi, dapat menggunakan udara panas suhu tinggi untuk pengeringan material dengan cepat. Perluasan yang kuat, desain mempertimbangkan margin produksi, bahkan jika output sedikit meningkat, tidak perlu mengganti peralatan.

- Distribusi pelat angkat mesin pengering rotary dan desain sudutnya masuk akal, kinerja andal, sehingga tingkat pemanfaatan panas tinggi, pengeringan merata, bahan bersih lebih sedikit, perawatan mudah.

Parameter teknis mesin pengering serpahan serpahan kayu berbentuk drum

| TIDAK. | MODEL | KAPASITAS | DAYA | DIAMETER PENGUMPAN | DIMENSI |

| 1 | SL-D800 | 500kg/jam | 2.2 7.5kw | ≤5mm | 15000*2600*3800mm |

| 2 | SL-D1000 | 1000kg/jam | 3 15kw | ≤5mm | 16000*2600*3800mm |

| 3 | SL-D1200 | 2000kg/jam | 3 18.5kw | ≤5mm | 18000*2800*4000mm |

| 4 | SL-D1500 | 3000kg/jam | 5.5 22kw | ≤5mm | 19000*3000*4500mm |

Video mesin pengering serpahan serutan kayu berputar

Produk Hot

Furnace Karbonisasi Vertikal untuk Produksi Arang Kayu keras

Furnace karbonisasi aliran udara saat ini adalah…

Line Produksi Briket Serbuk Kayu | Pabrik Kayu Panas Pini Kay

Line produksi briket serbuk kayu terutama mengekstrusi…

Mesin Pelet Kayu Industri untuk Dijual

Mesin pelet kayu mengacu pada proses kompresi…

Penghancur Palet Komprehensif untuk Menghancurkan Limbah Kayu

Penghancur palet komprehensif, yaitu limbah kayu…

Mesin Pembuat Arang: Panduan Utama untuk Produksi BioArang dengan ROI Tinggi

Mesin pembuat arang terbaru adalah solusi ideal…

Line Produksi Briket Batu Bara Sarang Lebah | Pabrik Pengolahan Arang Briket

Lini produksi briket arang sarang lebah dapat mengubah…

Pengering Kontinu untuk Mengeringkan Serbuk Kayu & Sekam Padi

Pengering serbuk kayu industri dan mesin pengering sekam padi…

Penghancur Batu Bara Arang | Mesin Penggiling Bubuk Arang

Mesin penghancur arang dapat menghancurkan berbagai…

Mesin Serutan Kayu untuk Tempat Tidur Hewan

Mesin serut kayu dapat memproses balok dan…

Tidak Ada Komentar.