Kolsfagnsmaskin: den ultimata guiden till högavkastande biokolproduktion

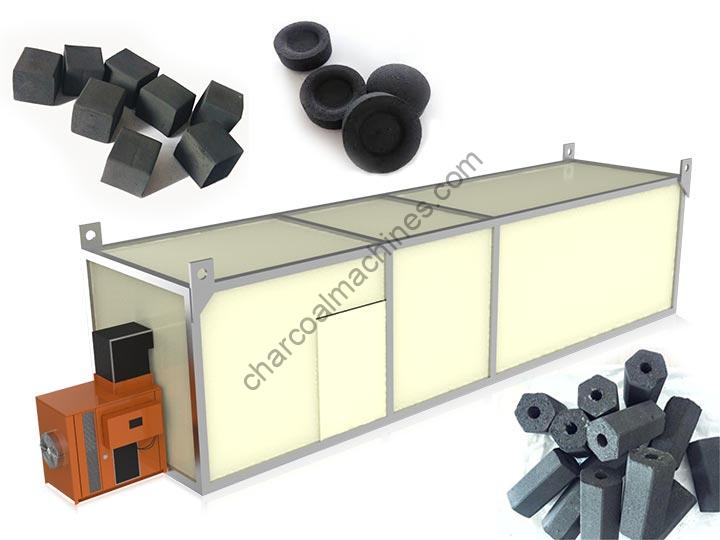

Newest charcoal making machine | Integrated carbonization machine

Kolsfagnsmaskin: den ultimata guiden till högavkastande biokolproduktion

Newest charcoal making machine | Integrated carbonization machine

Vipengele kwa Muhtasari

Are you looking for an efficient way to turn biomass waste into a high-value product? The Shuliy charcoal making machine is an advanced carbonization solution designed to convert various organic materials into premium biochar. This powerful pyrolysis plant is engineered for businesses aiming to capitalize on the circular economy, transforming waste streams like wood, coconut shells, rice husks, and even sludge into profitable resources. Whether you’re a large-scale agricultural enterprise or a waste management facility, this machine offers a sustainable and lucrative investment opportunity.

Our continuous charcoal making machine is built for industrial-scale production, with a processing capacity ranging from 800kg to 3 tons per hour, depending on the model. This makes it the ideal choice for medium to large charcoal processing plants and investors ready to lead in the sustainable energy market. Let’s explore how this technology can revolutionize your operations.

What Raw Materials Can a Charcoal Making Machine Process?

One of the greatest advantages of our charcoal making machine is its versatility. It can process a vast array of organic and inorganic wastes, making it a comprehensive solution for waste-to-energy projects. By carbonizing these materials, you not only produce high-quality charcoal but also significantly reduce waste volume, minimize environmental pollution, and create a valuable energy source.

Mali za Miti na Taka za Kilimo:

- Mabaki ya Mbao & Mashina ya Misitu: Vumbi la mbao, vipande vya mbao, matawi, mizizi ya mti, maganda, mianzi.

- Vibichi vya Kilimo & Maganda: Maganda ya nazi, maganda ya mchele, maganda ya karanga, maganda ya karanga za mzeituni, maganda ya karanga za karanga, maganda ya mzeituni.

- Shina za mazao na Malighafi nyingine: Mali, shina za hemp, maganda ya kahawa, majani ya miwa, maganda ya matunda.

Taka za Mitaa na Viwandani:

- Maji taka: Maji taka ya Mitaa, maji taka ya mto, maji taka ya viwandani, maji taka ya kuchapisha na kufagia rangi.

- Taka za Mitaa (MSW): Taka za nyumbani zilizopangwa, taka za kiwanda cha karatasi.

- Taka Nyingine: Mali ya wanyama, taka za kemikali kama vile coke iliyowashwa.

How Does a Charcoal Making Machine Work? A Step-by-Step Process

The charcoal production process is a highly efficient, continuous operation based on the principle of pyrolysis. Pyrolysis is the thermal decomposition of materials at elevated temperatures in an oxygen-deprived environment. Here’s how our machine turns waste into charcoal:

- Utaratibu wa Awali wa Malighafi: Kwa matokeo bora, malighali ya asili inapaswa kuwa na unyevu wa chini ya 15% na ukubwa mdogo wa zaidi ya 20mm. Malighali ambazo hazikidhi vigezo hivi zinashughulikiwa kwanza na kuchomwa na kisha dryer.

- Kula na Kuchemsha Kaboni: Malighafi iliyotayarishwa huingizwa kwenye tanuri kuu ya kuchemsha kaboni kupitia conveyor ya kiotomatiki. Ndani ya drum lenye safu mbili zinazozunguka, malighafi huendelea na pyrolysis ya joto la juu. Mchakato huu huchukua takribani dakika 15-25 kwa joto kati ya 380°C na 450°C.

- Urejeshaji wa Syngas na Joto la Kujitegemea: Kadri malighafi inavyochemka, huachilia gesi inayoweza kuwaka (syngas). Gesi hii hujumuishwa, kusafishwa kupitia mfumo wa kuondoa vumbi wa cyclone, kisha kuelekezwa tena kwenye chumba cha kuwasha ili kupasha tanuru. Baada ya awamu ya kupasha joto awali, mashine hujiendesha yenyewe, ikipunguza sana matumizi ya mafuta.

- Kutoa makaa na Baridi: Makaa ya mawe yaliyomalizika yanatolewa kupitia mfumo wa conveyor unaoingiza maji baridi. Mchakato huu huongeza baridi makaa ya mawe kwa haraka, kuzuia kuwaka tena na kufanya iwe salama kwa ukusanyaji na ufungaji wa haraka.

- Usafi wa Gesi ya Moshi: Tuuza gesi ya moshi iliyozidi inashughulikiwa kupitia mfumo wa usafi wa hatua nyingi (kama vile kunyunyizia maji, ufanisi wa kunyonya) ili kuhakikisha uzalishaji unakidhi viwango kali vya mazingira kabla ya kutolewa.

https://youtu.be/xVcNOnv-SHMWatch the charcoal making machine working process

Key Components of Shuliy’s Charcoal Making Machine

Our machine is an integrated system where each component is optimized for maximum efficiency, durability, and safety. Here are the core parts of our charcoal production line:

Mwili Mkuu wa Kuchemsha Kaboni (Reactor)

The heart of the machine. It features a double-layer drum made from high-temperature-resistant stainless steel. The robust design ensures even heating and long service life, with an inner cylinder thickness of 10mm for superior durability.

Mfumo wa Kukaanga

An optional but highly recommended component. The dryer pretreats raw materials to reduce moisture, which dramatically improves carbonization efficiency and the quality of the final charcoal.

Kabati la Kudhibiti Umeme la PLC

For safe, smart, and centralized operation. The PLC cabinet allows you to monitor and control all operational parameters in real-time, including temperature, pressure, and running speed, ensuring stable and secure production.

Mfumo wa Usafi wa Syngas na Baridi

This system is crucial for eco-friendly operation. It cleans the syngas before it’s reused as fuel and also allows for the collection of valuable by-products like wood vinegar and tar, creating additional revenue streams.

Why Invest in a Charcoal Making Machine? The Business Case

Investing in a Shuliy charcoal making machine is more than just purchasing equipment; it’s a strategic business decision with a high potential for return on investment (ROI). Here’s why:

- Badilisha Taka kuwa Faida: Badilisha malighafi za bei nafuu au zisizo na gharama kwa makaa ya mawe ya mahitaji makubwa, bidhaa yenye soko thabiti na inayokua.

- Mito mingi ya Mapato: Mbali na makaa ya mawe, unaweza kuuza bidhaa za ziada zenye thamani kama vile siki ya mbao (kwa dawa za kuua wadudu za asili) na lami (kwa matumizi ya viwandani).

- Rafiki wa Mazingira & Endelevu: Teknolojia hii inaendeleza uchumi wa mzunguko. Kwa kuzalisha biochar, unashiriki katika uhifadhi wa kaboni, kusaidia kupunguza gesi chafuzi. Hii inaweza kufanya biashara yako ipate haki za kaboni na motisha za serikali.

- Uwezo wa Kujitegemea wa Nishati: Mfumo wa kurejesha syngas huondoa gharama za mafuta kwa ufanisi mkubwa, kufanya mchakato wa uzalishaji kuwa na faida zaidi na kuhimili mabadiliko ya bei za nishati.

Wide Applications of the Final Charcoal (Biochar)

The charcoal produced by our machine is of high quality, with a fixed carbon content that can exceed 80-90%. This makes it suitable for a wide range of profitable applications:

- Kama Nishati: Nishati bora, rafiki wa mazingira kwa BBQ, shisha/hookah, na kupasha joto viwandani kama vile kiwanda cha simenti, viwanda vya boilers, n.k.

- Katika Kilimo (kama Biochar): Kurekebisha udongo kwa nguvu ambayo huboresha muundo wa udongo, huongeza umakini wa maji, huongeza ufanisi wa virutubisho, na huongeza mavuno ya mazao.

- Katika Viwanda: Inaweza kutumika kama wakala wa kupunguza katika uhandisi wa metali, au kuendelezwa zaidi ili kuzalisha kaboni hai kwa kusafisha maji na hewa.

- Utekelezaji wa Kaboni: Biochar hutoa njia thabiti, ya muda mrefu ya kuhifadhi kaboni ardhini, ikipinga mabadiliko ya hali ya hewa.

Technical Parameters of Shuliy Charcoal Making Machine

We offer several models to meet different production scales and investment budgets. Below are the specifications for our most popular charcoal making machines.

| Kitu | Details | |||

| Modeli | SL-JH-0812 | SL-JH-1015 | SL-JH-1218 | SL-JH-1320 |

| Hourly Feeding Capacity | 500kg | 0.8-1 Tons | 1.5-2Tons | 2.5-3Tons |

| Working Method | Continuous Carbonizing | |||

| Reactor Size | Φ800mm | Φ1000mm | Φ1300mm | Φ1700mm |

| Heating Materials | Charcoal, wood, diesel, natural gas, LPG, biomass pellets, etc. | |||

| Total Power | 40kw/h | 55kw/h | 60kw/h | 72kw/h |

| Floor Area (L*W*H) | 30m*15m*7m | 35*15*7m | 45*15*10m | 50*15*10m |

| Operating Pressure | Constant Pressure | |||

| Cooling Method | Recycling Water Cooling | |||

| Life Span | 5-8 Years |

charcoal making machine parameters

Why Choose Shuliy Machinery?

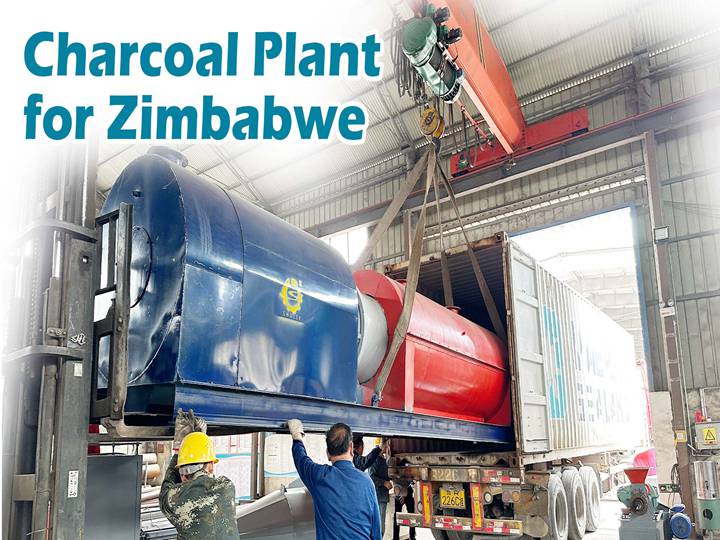

- Utaalamu wa Kupimwa: Kwa miaka mingi ya uzoefu wa utengenezaji na usafirishaji, tumefanikiwa kusakinisha viwanda vya uzalishaji wa makaa ya mawe katika nchi nyingi, ikiwa ni pamoja na Malaysia, Brazil, na bara Ulaya.

- Ubora na Uimara: Tunatumia vifaa vya kiwango cha juu, vinavyostahimili joto na uhandisi thabiti kujenga mashine zinazodumu, kuhakikisha unapata thamani bora kwa uwekezaji wako.

- Suluhisho zilizobinafsishwa: Timu yetu ya uhandisi itashirikiana nawe kubuni mstari wa uzalishaji wa makaa ya mawe uliobinafsishwa kulingana na malighafi yako maalum, hali ya tovuti, na malengo ya biashara.

- Huduma Kamili: Tunatoa msaada kamili, kuanzia ushauri wa awali na muundo wa suluhisho hadi usakinishaji wa nje ya nchi, mafunzo kwa waendeshaji, na huduma ya baada ya mauzo ya maisha yote.

Tazama usakinishaji wetu wa kiwanda cha makaa ya mawe chenye mafanikio nchini Malaysia

Frequently Asked Questions (FAQ) about the Charcoal Making Machine

1. Je, bei gani la makaa ya mawe la kutengeneza makaa ya mawe?

The price varies depending on the model, capacity, and configuration (e.g., inclusion of a dryer, crusher). To get an accurate quote tailored to your needs, please contact our sales team with your raw material type, desired capacity, and final charcoal usage. We will provide a detailed proposal and price list.

2. Je, tofauti kati ya mashine hii na tanuri la jadi ni nini?

Our continuous charcoal making machine is far more efficient, eco-friendly, and controllable than a traditional kiln. It offers continuous production (vs. batch processing), recycles combustible gas to save fuel, has a complete smoke purification system to prevent pollution, and produces higher quality charcoal with a consistent yield.

3. Je, maisha ya huduma ya mashine ni muda gani?

With proper maintenance, the main components of the Shuliy charcoal making machine have a service life of 5-8 years. We use high-quality, durable materials to ensure longevity and provide comprehensive after-sales support for spare parts.

4. Je, naweza kuona mashine ikifanya kazi?

Absolutely. We have numerous videos of our machines in operation at client sites around the world. We can also arrange a visit to our factory or a nearby client’s plant, depending on your location and availability. Please contact us to coordinate.

Get Your Customized Charcoal Production Solution Today!

Ready to transform waste into wealth and build a sustainable business? The Shuliy charcoal making machine is your key to unlocking the potential of biomass. Contact us today for a free consultation and a personalized quote. Our experts are ready to help you launch your profitable charcoal production project.

Mashine ya Kutengeneza Makaa

This newest charcoal making machine is carbonization equipment designed and manufactured by the Shuliy factory for processing various types of biomass charcoal. This integrated carbonization machine can carbonize biomass wastes, crop wastes, municipal wastes, sludge, animal manure, etc. This charcoal making machine is also efficient equipment for processing coconut shell charcoal, wood charcoal, sawdust charcoal, bamboo charcoal, palm shell charcoal, etc.

Chapa ya Bidhaa: Shuliy Group

Sarafu ya Bidhaa: USD

Bei ya Bidhaa: 27000

Thamani ya Bei Inakoma: 2028-07-31

Bidhaa Zilizopo Sokoni: Zilizopo Sokoni

5

Pros

- I am very satisfied with this equipment!

- Great! The quality of the charcoal produced has been greatly improved.

- Shuliy helped me with installation and technical guidance, and will cooperate again.

- This machine produces very good charcoal.

- The preferred equipment for charcoal producers.

Taarifa

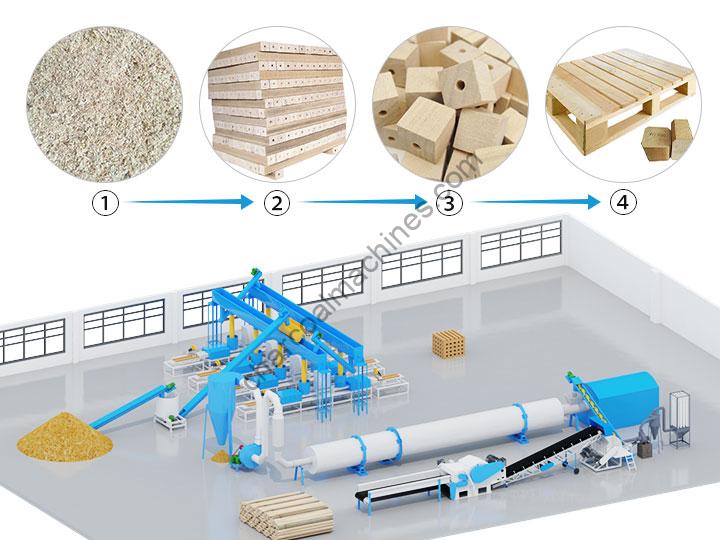

Industriell träpelletsmaskin till försäljning

Mashine ya pellet ya mbao inahusu kusukuma…

Kikaango cha Kukausha cha Kuendelea kwa Kukausha Sawdust & Maganda ya Mchele

Vifaa vya kukausha vumbi la mbao na mashine za kukausha pumba za mchele…

Mstari wa Utengenezaji wa Pellet za Mbao za Mafuta ya Mimea

Mstari wa uzalishaji wa unga wa mbao wa biomass ni wa…

Horison kolsugn för biochar kolisering

Kiwanda cha makaa ya mkaa cha mwelekeo ni…

TräKross för att göra sågspån av allt träavfall

Mashine za kuchakata mbao ni vifaa vya kawaida vya kusaga kwa…

sågverkmaskin för bearbetning av timmer

Mashine za kiwanda cha mbao zinazokatwa kwa mashine za kiwanda zinaweza kukata magogo kuwa…

Mashine ya Kukausha Mkaa wa Mbao ya Kundi yenye Utendaji mzuri

Mashine ya kukausha makaa ya mawe inatumiwa hasa kwa…

Mashine ya Makaa na Mstari wa Utengenezaji wa BioCharcoal

Mashine za kutengeneza mkaa zinaweza kugeuza taka za biomass,…

Träblockproduktionslinje för tillverkning av pressade träpallblock

Mstari wa uzalishaji wa kuta za mbao unaweza kushughulikia…

Hakuna Maoni.