Latest Charcoal Making Machine to Make Biocharcoal

Newest charcoal making machine | Integrated carbonization machine

Latest Charcoal Making Machine to Make Biocharcoal

Newest charcoal making machine | Integrated carbonization machine

Features at a Glance

This newest charcoal making machine is carbonization equipment designed and manufactured by the Shuliy factory for processing various types of biomass charcoal. This integrated carbonization machine can carbonize biomass wastes, crop wastes, municipal wastes, sludge, animal manure, etc. This charcoal making machine is also efficient equipment for processing coconut shell charcoal, wood charcoal, sawdust charcoal, bamboo charcoal, palm shell charcoal, etc.

This continuous charcoal machine can realize the large-scale production of charcoal, and its processing capacity per hour is between 800kg and 3t (based on different models). Therefore, this charcoal carbonizer is very suitable for medium and large charcoal processing plants and charcoal processors with high investment budgets.

Raw materials for integrated charcoal making machine

The continuous charcoal making machine has a wide range of applications, and almost all biomass waste, sludge, domestic waste, industrial waste, etc. can be carbonized. The carbonization furnace can not only produce a large number of high-quality charcoal products but also can reduce the volume of garbage, reduce environmental pollution and save energy by carbonizing a lot of garbage or industrial wastes.

Common processable waste biomass raw materials: straw scraps, rice husk, hemp straw, sawdust, olive pits, bark, bamboo powder, bamboo chips, branches, tree roots, coconut shells, walnut shells, palm kernel shells, peanut shells, Jujube pits, fruit bran, beef bone, coffee grounds, pine cones, pine bark, poplar, cow dung, etc.

Various types of garbage and sludge can be carbonized: domestic garbage, paper mill garbage, municipal sludge, river sludge, industrial sludge, printing, dyeing sludge, etc.

Chemical wastes: carbonization of activated coke, blue carbon, magnesium oxide, sodium oxide, and other materials.

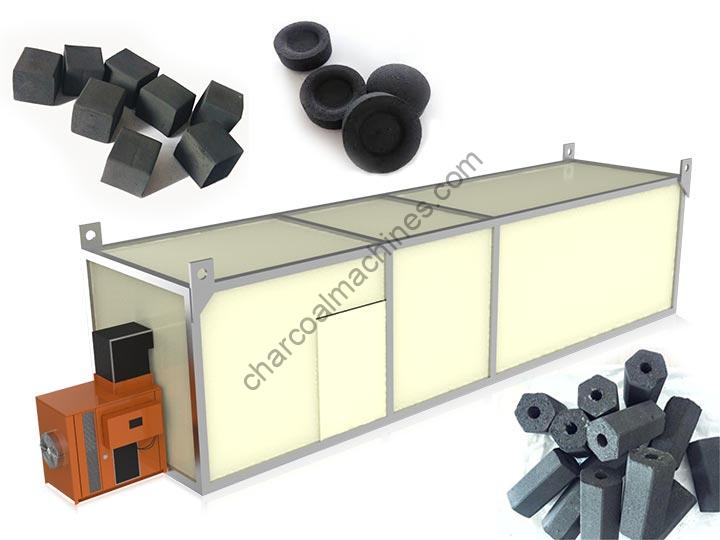

Carbonizing effect display of continuous charcoal making machine

Compared with the previous carbonization equipment, the processing efficiency of the continuous charcoal machine will be higher, and the effect of the processed charcoal products will be better.

At present, most domestic and foreign customers choose this carbonization machine to produce coconut shell charcoal, sawdust charcoal, rice husk charcoal, bamboo charcoal, palm shell charcoal, peanut shell charcoal, hemp stalk charcoal, etc.

A small number of customers are from municipal departments in different countries, and they purchase this carbonization equipment for the treatment of various types of domestic waste and industrial sludge.

Components of Shuliy charcoal making machine for sale

The structure of each part of this newest charcoal carbonization machine is optimized. The structure of the complete set of carbonization equipment mainly includes the casing, the carbonization main engine (segmented drum), the combustion chamber, the motor, the transmission wheel structure, the feeding, and discharging system, etc.

In addition, according to the actual production needs of different customers, we will provide customers with a series of supporting equipment to choose from, such as dryers, electric control cabinets, flue gas purification devices, etc.

How does the integrated carbonization furnace work?

Drying system for carbonization machine

The dryer can pretreat the raw materials and appropriately reduce the moisture content of the raw materials, so as to improve the processing efficiency of the carbonization machine. The dryer can generally dry the moisture of the raw materials to less than 25%.

Feed elevator for adding raw materials

Usually, the carbonization main body of the carbonization furnace is relatively high, and it needs to be automatically fed by means of a hoist feeder. The height of this feed elevator can be customized according to customer needs. And its transfer speed can be adjusted.

Carbonizing body for making charcoal

The main part of the integrated charcoal making machine is a rotating drum structure that converts raw materials into charcoal. The drum structure is double-layered, all of which are made of high-quality stainless steel and are very resistant to high temperatures.

The thickness of the steel plate of the inner cylinder is about 10mm, and the thickness of the steel plate of the outer cylinder is about 6mm. The material of the outer shell is channel steel, and in order to improve the durability of the outer shell, our factory specially designed the steel plate reinforcement with reinforcing ribs on the surface of the outer shell.

Ignition device for continuous carbonizing

The ignition device is connected to the combustion chamber of the carbonization furnace and is used for igniting the combustible gas leading to the combustion chamber. In fact, the pilot device and liquefied gas are only used in the initial stage of carbonization.

When the material inside the carbonization machine produces combustible gas during the carbonization process, the charcoal making machine will recycle the combustible gas for combustion and heating, which can greatly save fuel consumption.

Electric control cabinet for safe and smart operation

Generally, the power consumption of different types of continuous carbonization furnaces is generally 40kw and above. In order to ensure safe production and convenient operation, we recommend customers purchase the matching device of the carbonization machine, that is, the electric control cabinet. On the electric control cabinet screen, we can set and view all the data of the machine operation, such as temperature, operating speed, pressure value, etc.

Discharging device of carbonization machine

The discharge device of the coconut shell charcoal machine is located below the carbonization furnace. Usually, the delivery of charcoal is conveyed by belt. In order to quickly reduce the temperature of the carbon finished product and facilitate the collection and transportation of the carbon, a water cooling spray device is designed above the discharge conveyor.

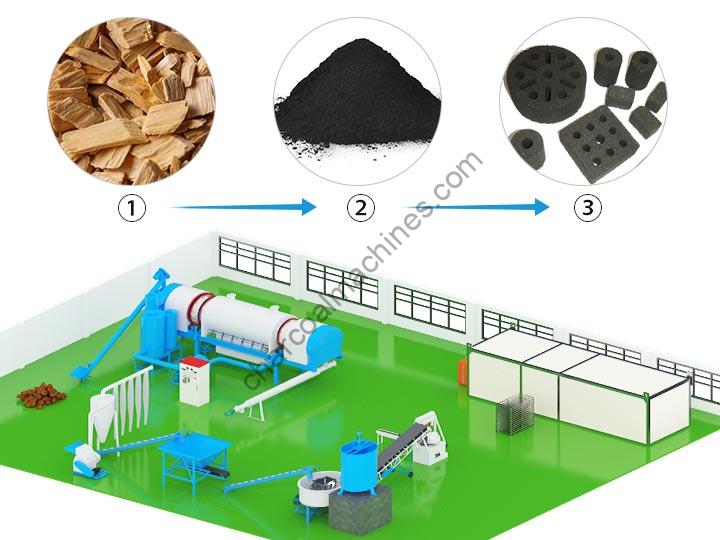

How is charcoal making process with carbonization machine?

- Raw material crushing & drying. Materials with moisture higher than 25% and sizes larger than 20mm need to be crushed by a pulverizer first and then sent to a sawdust dryer for drying.

- Raw material carbonization & discharge. Use the pilot device to carbonize the main furnace for preheating. Then, the dried material is conveyed to the feed port of the carbonization machine through the conveyor belt. The material enters the main carbonization furnace with the carbonization drum for carbonization. Taking coconut husk and rice husk as an example, after carbonization for 18-20 minutes, the material can be discharged through the discharge conveyor.

- Combustible gas generation. Usually, the combustible gas will be generated after the raw material enters the carbonization furnace for about 20 minutes. The generated combustible gas first enters the cyclone dust removal system for cleaning, desulfurization, and dust removal, and then enters the condenser to be separated into wood vinegar and tar. The remaining gas is drawn to the outside of the main furnace by an induced draft fan and heats the main furnace.

- Hot flue gas reuse. A part of the waste heat flue gas can be used to heat the dryer as a heat source for drying raw materials. The remaining flue gas can be filtered by the dust removal system (water cleaning, water spraying, etc.) and then discharged into the atmosphere.

Technical parameters of charcoal making machine

| Item | Details | |||

| Model | SL-JH-0812 | SL-JH-1015 | SL-JH-1218 | SL-JH-1320 |

| Hourly Feeding Capacity | 500kg | 0.8-1 Tons | 1.5-2Tons | 2.5-3Tons |

| Working Method | Continuous Carbonizing | |||

| Reactor Size | Φ800mm | Φ1000mm | Φ1300mm | Φ1700mm |

| Heating Materials | Charcoal, wood, diesel, natural gas, LPG, biomass pellets, etc. | |||

| Total Power | 40kw/h | 55kw/h | 60kw/h | 72kw/h |

| Floor Area (L*W*H) | 30m*15m*7m | 35*15*7m | 45*15*10m | 50*15*10m |

| Operating Pressure | Constant Pressure | |||

| Cooling Method | Recycling Water Cooling | |||

| Life Span | 5-8 Years |

Charcoal making machine for production of wood pellet charcoal

Continuous charcoal processing machine working video

Charcoal production plants in different countries!

Malaysia charcoal plant with Shuliy charcoal machines

Charcoal Making Machine

This newest charcoal making machine is carbonization equipment designed and manufactured by the Shuliy factory for processing various types of biomass charcoal. This integrated carbonization machine can carbonize biomass wastes, crop wastes, municipal wastes, sludge, animal manure, etc. This charcoal making machine is also efficient equipment for processing coconut shell charcoal, wood charcoal, sawdust charcoal, bamboo charcoal, palm shell charcoal, etc.

Product Brand: Shuliy Group

Product Currency: USD

Product Price: 27000

Price Valid Until: 2028-07-31

Product In-Stock: InStock

5

Pros

- I am very satisfied with this equipment!

- Great! The quality of the charcoal produced has been greatly improved.

- Shuliy helped me with installation and technical guidance, and will cooperate again.

- This machine produces very good charcoal.

- The preferred equipment for charcoal producers.

Hot Product

Compressed Wood Pallet Machine for Molded Pallet Production

The compressed wood pallet machine is a piece…

Continuous Dryer for Drying Sawdust & Rice Husk

Industrial sawdust dryers and rice husk drying machines…

Batch Charcoal Drying Machine with Good Performance

The charcoal dryer machine is mainly used to…

Briquette Cutters for making briquette charcoal as required

The charcoal briquettes cutting machine is used to…

Charcoal Coal Crusher | Charcoal Powder Grinder Machine

The charcoal crusher machine can mainly pulverize various…

Wood Pallet Block Machine for Making Pallet Blocks

Commercial wood pallet block making machines can extrude…

Honeycomb Coal Briquette Production Line | Briquettes Charcoal Processing Plant

The honeycomb coal briquette production line can turn…

Compressed Wooden Pallet Production Line

The compressed wooden pallet production line is a…

Wood Hammer Mill for Recycling Wood Scraps

Wood hammer crusher mill can crush wood chips,…

No Comments.