Honeycomb Coal Briquette Production Line | Briquettes Charcoal Processing Plant

Honeycomb Coal Briquette Production Line | Briquettes Charcoal Processing Plant

The industrial honeycomb coal briquette production line is a series of equipment for deep processing coal powder and charcoal powder, mainly crushers, mixers, coal briquettes forming machines, and dryers. Through this briquettes charcoal processing plant, we can make coal powder and charcoal powder into solid briquettes of different shapes. You can use these coal or coal or charcoal briquettes for barbecues, boiler burning, restaurants, heating, and other purposes. The configuration of the honeycomb coal briquettes production line can be customized according to specific customer needs, and its output is 500kg/h to 2t/h.

Features of the honeycomb coal & charcoal briquettes

Honeycomb briquettes are actually a special shape of charcoal briquettes. The shape of such briquettes is usually a porous honeycomb structure. The main advantages of this honeycomb coal or charcoal briquettes are large surface area, good air permeability, easy ignition, high burning value, long burning time, etc.

In addition, in addition to the classic honeycomb shape, the honeycomb briquettes production line can also produce coal briquettes and charcoal briquettes of various shapes by changing different molding molds, such as square honeycomb briquettes, hexagonal coal briquettes, etc. And the number of holes on the surface of the finished briquettes can be customized, usually 1, 2, 3, 4, 5, 6, 9, 12, 14, 16, 18, 19, 20, etc.

Classification of honeycomb briquettes production line

Honeycomb briquettes production line is just a name for this coal processing technology. In fact, according to the different raw materials to be processed, the production line configuration is also different. For example, the processing lines for coal powder and charcoal powder are very different. Therefore, we can divide the honeycomb briquettes production line into honeycomb coal briquette production line and honeycomb charcoal briquette production line.

Honeycomb coal briquette production line

The coal briquettes processing plant mainly uses coal slag, coal blocks, coal powder, etc. as raw materials to produce coal briquettes. The main equipment of the production line includes a silo, coal pulverizer, biaxial mixer, coal briquettes press machine, and briquettes dryer.

Machine list of honeycomb coal briquette production line

| No. | Machine name |

| 1 | Automatic feeding bin |

| 2 | Coal crusher |

| 3 | Coal powder mixer |

| 4 | Honeycomb coal briquettes press machine |

| 5 | Coal briquettes dryer |

Automatic feeding bin

This small silo is mainly used to store coal raw materials. The storage silo also has the function of uniform feeding, which can continuously convey the raw materials in the next working link. There is a screw at the bottom of the silo, which can quantitatively convey materials to the conveyor belt at the bottom.

Coal crusher

Coal crusher is suitable for crushing raw materials and returned materials, such as coal, charcoal, limestone, cement clinker, gypsum, gangue, slag, iron ore, etc. The coal pieces enter from the inlet and collide with the high-speed rotating hammer inside the housing. Then, coal pieces will become coal powder (below 3mm) after several times of impact and will be discharged from the lower outlet.

Coal powder mixer

The coal powder mixer can be used to mix various dry or wet coal powder, coal powder, fine sand and mineral powder, and other materials. It can mix coal powder quickly and evenly. Due to the low viscosity of coal powder, we can add a small amount of binder or a small amount of clay when mixing the coal powder.

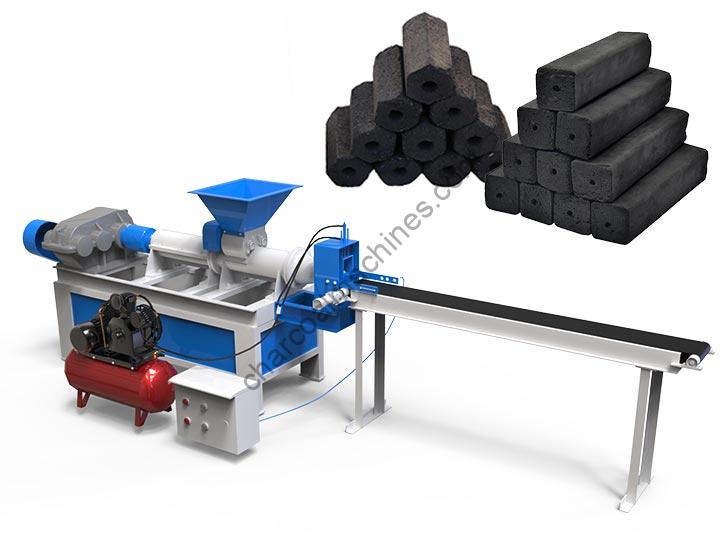

Honeycomb coal briquettes press machine

This briquette machine is the main forming equipment for processing honeycomb briquettes. The coal briquettes press machine can press the mixed coal powder into coal briquettes within molds through mechanical extrusion force. Moreover, we can process coal briquettes of different shapes by changing the molds of this equipment.

Coal briquettes dryer

After the honeycomb coal briquettes are processed, we can dry the briquettes by natural drying. Or, we can use this box-type drying machine to quickly dry coal briquettes. The briquettes drying machine is mainly composed of a box-type shell and carts. Several layers of trays can be placed on the carts. We need to load coal briquettes into trays, and then put them in the drying room for drying.

Compressed Coal Briquettes Making Machine Video

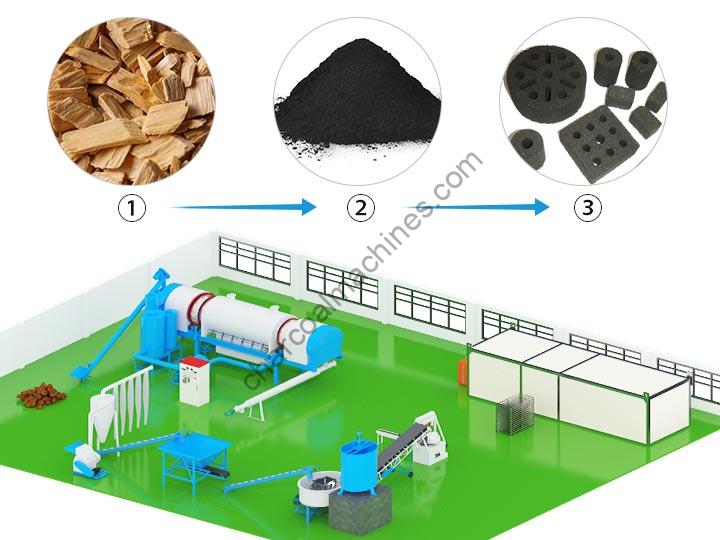

Honeycomb charcoal briquette processing plant

The raw materials of the honeycomb charcoal processing line are mainly various kinds of biomass raw materials, such as wood chips, coconut husk, rice husk, straw scraps, etc.

The production process of this production line mainly includes continuous carbonization, carbon crushing, charcoal powder mixing (adding binder), charcoal briquettes molding, and briquettes drying. If the customer’s raw material is charcoal powder or lump charcoal, there is no need to use a carbonization furnace for raw material carbonization.

Machine list of honeycomb charcoal briquette production line

| No. | Machine name |

| 1 | Continuous carbonization furnace |

| 2 | Charcoal crusher |

| 3 | Charcoal powder mixer |

| 4 | Binder mixer |

| 5 | Honeycomb charcoal briquettes forming machine |

| 6 | Charcoal briquettes dryer |

Continuous carbonization furnace

The continuous carbonization furnace is currently the most efficient continuous carbonization equipment. The carbonization furnace can directly carbonize most of the biomass raw materials and cool and discharge them. The carbonization temperature of the continuous carbonization furnace is between 500°C and 800°C. Its output is between 800kg/h-1000kg/h.

Charcoal crusher

The charcoal pulverizer mainly quickly pulverizes the charcoal product after being carbonized by the carbonization furnace. If the raw material for carbonization is rice husk and sawdust, it does not need to be crushed. But if the customer’s carbonized raw material is coconut shell or wood chips, the volume of the carbonized product will be relatively large, so it needs to be crushed by a charcoal crusher.

Charcoal powder grinder & mixer

The charcoal powder mixer not only has the function of stirring but also has the function of further crushing the charcoal powder. It can grind the charcoal powder more finely. In addition, in the process of stirring the carbon powder, we usually need to add an appropriate amount of binder and water to the mixer to increase the viscosity of the carbon powder.

Binder mixer

The binder mixing tank is mainly used to mix water and binder powder uniformly in a certain proportion. For the briquettes production line with a relatively large production volume, this mixer is very practical. There is a stirring shaft in the stirring tank, which is driven by a motor. The processing volume of each batch of this mixer is 0.6m³. The size of the mixer can be customized according to customer needs.

Honeycomb charcoal briquettes press machine

We put the evenly stirred charcoal powder into the hopper of the honeycomb briquettes molding machine. Then the carbon powder in the hopper will be quantitatively injected into the extrusion die to be squeezed to be made into various shapes of charcoal briquettes. It is common to use charcoal powder to make honeycomb briquettes in a hexagonal shape.

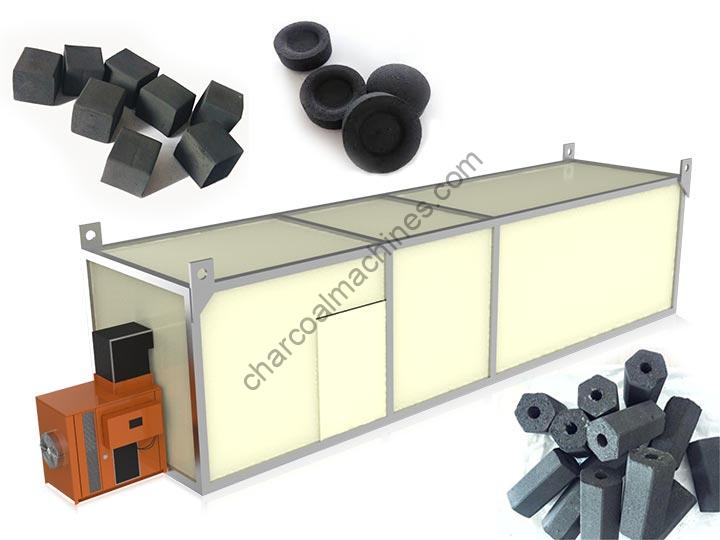

Charcoal briquettes drying machine

In the honeycomb charcoal briquettes processing plant, our commonly used briquettes dryer is also this kind of box dryer. The drying efficiency of this dryer is very high, and the drying effect is also very good. The dried honeycomb charcoal briquettes have a smooth surface without cracks. The heating method of this charcoal briquettes dryer can choose electric heating, gas heating, and solid fuel heating.

Large hexagonal briquettes processing plant in Uganda

Advantages of the honeycomb briquettes production line

- The honeycomb coal & charcoal briquettes production line designed by our Shuliy company can be customized. Our factory can make suitable honeycomb coal briquettes processing plan for customers according to specific customer needs and budget. It can ensure that customers invest in briquettes production business at the lowest cost.

- The charcoal or coal briquettes produced by the honeycomb briquettes processing plant have a high density and are not easily broken during transportation. In addition, due to the large surface area, such briquettes are easy to ignite and burn well. Therefore, the demand for this honeycomb briquettes in the market has always been great.

- As a powerful manufacturer, our factory usually has a certain amount of equipment inventory. Therefore, we can ensure timely delivery arrangements for customers. Moreover, any equipment in our factory is covered by the warranty period, and our factory also has a very complete after-sales service to ensure the customer’s experience.

Honeycomb coal briquette production line video

Hot Product

Vertical Carbonization Furnace For hardwood Charcoal Production

The airflow hoisting carbonization furnace is currently the…

Charcoal Coal Crusher | Charcoal Powder Grinder Machine

The charcoal crusher machine can mainly pulverize various…

Briquette Press for Making Sawdust Briquettes from Biomass Wastes

The industrial sawdust briquette machine is mainly used to…

Biomass Wood Pellet Production Line

The biomass wood pellet production line is an…

Charcoal Coal Briquettes Extruder Machine for Charcoal Plant

Charcoal briquette machine can extrude charcoal & coal…

Wood Pellet Machine for Making Biomass Pellet Fuel

Wood pellet machine refers to the compression of…

Batch Charcoal Drying Machine with Good Performance

The charcoal dryer machine is mainly used to…

Continuous Dryer for Drying Sawdust & Rice Husk

Industrial sawdust dryers and rice husk drying machines…

Saw Mill Machine for Processing Lumbers

Industrial wood sawmill machines can saw logs into…

No Comments.