Wood Debarker Machine for Peeling Logs

Wood Debarker Machine | Log Flaking Machine

Wood Debarker Machine for Peeling Logs

Wood Debarker Machine | Log Flaking Machine

Wood debarker machine, also known as the log flaking machine, is an important part of papermaking, wood processing, and other industries. It is widely used in paper mills, plywood mills, logging mills, etc. Using a wood peeling machine can greatly save labor and reduce labor costs.

Brief introduction to the wood debarker machine

The wood peeling machine currently produced by our company has two models: a vertical peeling machine and a horizontal peeling machine. Our log debarking machine can effectively remove the bark of wood and can peel wood of different tree species, diameters, and lengths. It can be equipped with a conveyor belt to transfer wood to the feed inlet of the wood peeling machine. It is a piece of perfect supporting equipment for assembly line operation and automated production.

Raw materials of the log debarking machine

This series of wood debarker is widely used in paper mills, board mills, forest farms and other industries. It has a wide range of applications, such as eucalyptus, fruit trees, pines, locust wood, beechwood, acacia wood and so on. It is not only suitable for logs and branches, but also for peeling some frozen wood and wood with high humidity. The quality of the peeled wood is better and can be sold at higher prices in the market.

Wood flaking machine feedback video

Vertical wood debarker

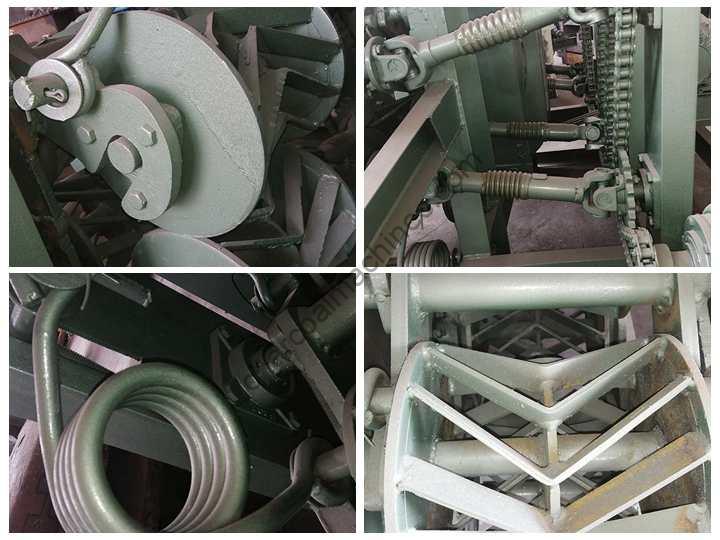

Wood peeling machine structure

The log debarking machine is mainly composed of a frame, four feed rollers and four discharge rollers, a cutter head and four blades, two motors, which are respectively used to control the cutter head and forced feeding.

Working principle of the log debarking machine

When the vertical log flaking machine is working, the wood is bitten by the four rollers at the feed port and pushed forward. During the advancing process, the four blades located in the middle of the machine continuously rotate at high speed to scrape the bark off the surface of the wood. During the whole process, the wood advances at a constant speed, and the peeling effect is excellent.

The peeled logs or tree branches can further be processed by the wood chipper for making high-quality wood chips.

Advantages of the vertical log debarking machine

- The wood can be processed in a wide range of sizes by the wood debarkers, the minimum diameter of wood is 5 cm, and the maximum diameter is 35 cm;

- The peeling speed of the wood debarkering machine is fast and stable, which can reach 10m/min;

- The processed wood is very clean, and the blade will not harm the wood itself and cause waste.

Parameters of the vertical wood debarker machine

| Type | Size | Weight | Knife quantity(pcs) | Max diameter (cm) | Motor power (kw) |

| SL250 | 1800*1000*1800 | 0.8t | 4 | 5-25 | 4+1.5 |

| SL320 | 2450*1400*1700 | 2t | 4 | 10-30 | 7.5+2.2 |

Small log peeler machine video

Horizontal log peeling machine

Wood peeling machine structure

The horizontal wood debarker machine is composed of one or two peeling rollers, a feed port, one or two motors, a discharge port, a bark outlet and a large trough.

Working principle of the wood debarker

The trough-type wood debarking machine uses a peeling roller to rotate so that the wood section is cyclically moved in the trough, and at the same time, it also rotates around the wood section’s own axis, as well as irregular beating. At this time, the continuous friction and collision between the wood section and the roller, and between the wood section and the wood section make the bark separate quickly and achieve the peeling effect.

Advantages of the wood peeling machine

- It can handle small size wood that the vertical type can not peel;

- A large amount of wood can be processed at one time, and wood of different sizes can be processed at the same time.

- The roller of the debarking machine is very durable, not easy to be damaged, has no accessories, and has a long service life.

Parameters the horizental wood debarker

| Type | Capacity (t/h) | Motor Power (kw) | Size (mm) | Weight (t) |

| 6m (single roller) | 3-7 | 7.5 | 6300*1200*1500 | 2.5t |

| 6m (double rollers) | 7-15 | 7.5+7.5 | 6300*1310*1550 | 4t |

| 9m ( double rollers) | 15-25 | 7.5+7.5 | 9000*1500*1600 | 5t |

| 12m (double rollers) | 25-30 | 7.5+7.5 | 12600*1500*1650 | 8t |

Video of the log debarking machine

Loading and delivery of the wood debarker

Factors affecting wood debarker efficiency

There are some factors that can affect the log peeling machine’s efficiency. Generally speaking, wet wood has a better peeling effect than dry wood.

Generally speaking, the fresher the logs, the better the peeling effect. This is because the fresh bark is brittle and easy to peel off. The dry bark, on the other hand, becomes fibrous due to a lack of moisture, so it is not easy to peel off.

Therefore, humidity is one of the factors that will influence the efficiency of debarking machine.

Hot Product

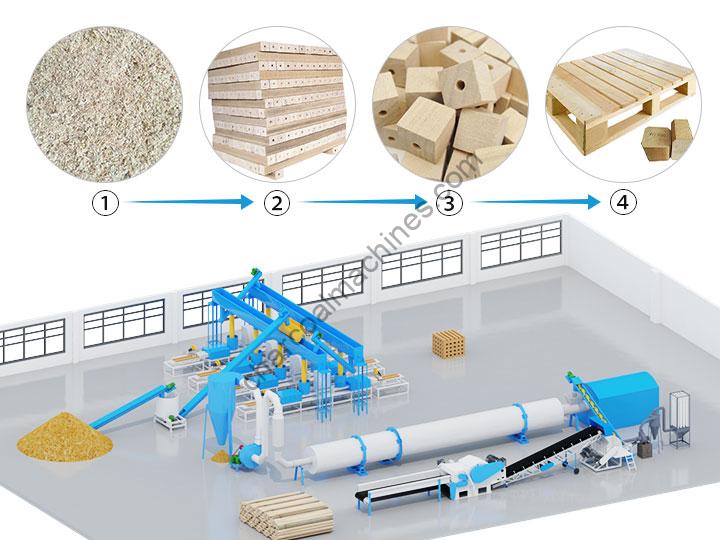

Wood Block Production Line for Making Compressed Wood Pallet blocks

Wood block production line can process high-quality compressed…

Continuous Dryer for Drying Sawdust & Rice Husk

Industrial sawdust dryers and rice husk drying machines…

Drum Wood Chipper for Wood Chips Mass Production

The wood chipper shredder machine mainly can be…

Latest Charcoal Making Machine to Make Biocharcoal

The newest charcoal making machine is the ideal…

Wood Powder Grinder Machine for Making Wood Flour

The wood powder machine is used for the…

Comprehensive Pallet Crusher for Shredding Wood Wastes

The comprehensive pallet crusher, namely the scrap wood…

Vertical Carbonization Furnace For hardwood Charcoal Production

The airflow hoisting carbonization furnace is currently the…

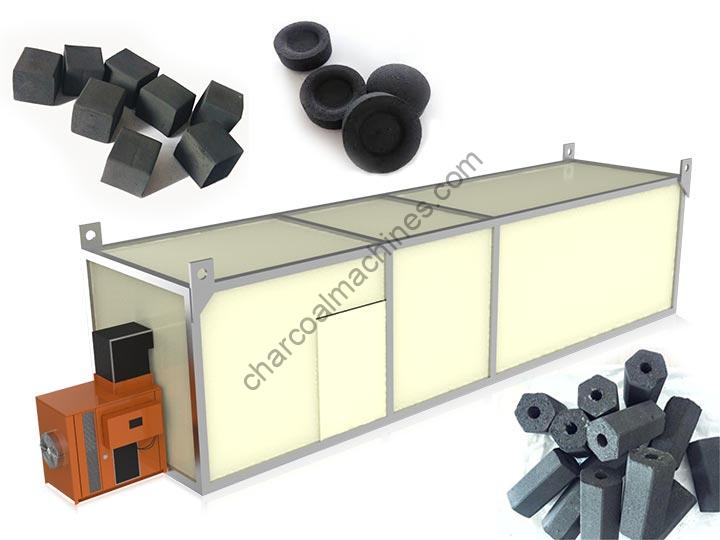

Batch Charcoal Drying Machine with Good Performance

The charcoal dryer machine is mainly used to…

Thermal Shrink Packing Machine for Packaging Sawdust Pini Kay Briquettes

This automatic thermal shrink packing machine can be…

No Comments.