Comprehensive Pallet Crusher for Shredding Wood Wastes

Wood Pallet Crusher | Scrap Wood Waste Shredder Machine

Comprehensive Pallet Crusher for Shredding Wood Wastes

Wood Pallet Crusher | Scrap Wood Waste Shredder Machine

The comprehensive pallet crusher, namely the scrap wood shredder, or waste wood pallet grinder, is a large and medium-sized continuous crushing equipment, mainly used to crush and recycle various waste packaging wooden boxes, waste wooden furniture, waste building templates, nailed wood scraps, waste wood pallets, branches, logs, hardwoods, etc. This continuous pallet crusher machine can quickly crush all kinds of scrap wood wastes into scraps.

The wood chips and sawdust processed by the comprehensive pallet crusher can be used for papermaking, power generation, and processing into biomass pellets. This kind of continuous wood crushing equipment is often used in various large construction factories, farms, forest farms, etc. to recycle all kinds of wood.

The wood pallet crusher machine is often used with automatic conveying equipment of different lengths to realize automatic production. The processing efficiency of the comprehensive crusher is very high, and the nails can be separated automatically when processing the wood with nails. Its output per hour can be as high as about 50 tons.

Applications of the comprehensive pallet crusher machine

Processing materials

- Straws and agricultural residues: crop straws, rice straws, crop shells, and waste residues from the processing of agricultural and sideline products.

- Trees and cutting and processing residues: piles, branches, roots, leaves, etc. of various trees, as well as wood shavings, wood chips, broken wood, and other forestry processing wastes.

- Dismantling of used formwork and wooden pallets: various specifications of used formwork, formwork fragments, building formwork with nails, waste wooden furniture, wooden pallet dismantling brackets, etc.

Applications of wood pallet shredder machine

The comprehensive crusher is suitable for waste formwork processing plants, bamboo plywood processing plants, wood-based panel plants, composite board plants, power plant boilers, etc., as well as individual wood processing plants.

This waste pallet crusher can crush the raw materials into wood chips about 5-8 cm in size or smaller wood chips. This kind of continuous crushing equipment has a wide range of applications and high output. The processed products are usually used as combustion raw materials for biomass power plants.

Structure of the comprehensive pallet crusher

The structure of the comprehensive crusher mainly includes feeding conveying, crushing saw, pressing roller, screen, discharging conveying, and so on. Among them, there are two types of crushing saws for this machine. One is a blade saw, which mainly processes wood without nails. The other is the tiger claw saw, which mainly handles materials with nails.

The comprehensive pallet crusher can use a grab machine to replace manual feeding and can crush various types of biomass materials such as templates, straws, and branches. The continuous pulverizer can also be operated with a remote control according to requirements, or with an automatic feed start or stop function. When the load of the main motor is too large, the feeding of the machine can start and stop automatically, which can greatly save labor and ensure production safety.

Working principle of the scrap wood wastes shredder machine

When the wood comprehensive crusher is working, the motor drives the rotor to rotate at a high speed. At the same time, the feeding conveyor rotates slowly under the drive of the motor. The material is put into the feeding conveyor by the grabbing machine. The material shifting teeth on the inner wall of the hopper will evenly transfer the material to the rotor while the hopper is rotating.

The high-speed rotating rotor encounters the material through the cutting and tearing of the blade on the rotor. The materials that have entered the preliminary crushing will not fall on the screen in the crushing chamber under the action of their own gravity and the impact of the rotor. The materials that meet the requirements will be discharged through the screen, and those that do not meet the requirements will be carried out in the crushing chamber. Two or even three times of crushing processing until it meets the requirements.

Parameters of the comprehensive wood crusher

| Model | SL-C-1300 | SL-C-1400 | SL-C-1600 |

| Feeding inlet size | 1300*500mm | 1400*800mm | 1600*800mm |

| Feeding maximum diameter | 400mm | 500mm | 600mm |

| Output size | Less than 100mm | Less than 100mm | Less than 100mm |

| Input conveyor | 6m | 6m | 6m |

| Output conveyor | 8m | 10m | 10m |

| Blades(pcs) | 20 | 32 | 66 |

| Capacity | 8-10 t/h | 10-15t/h | 20-30t/h |

| Total power | 156.5 kw | 213.5 kw | 233.5kw |

| Overall size | 8600*2000*2300mm | 9600*2400*3300mm | 12500*2800*3200mm |

Comprehensive pallet crusher video

Customer case of comprehensive pallet crusher machine

We exported this integrated crusher to Bangladesh to help customers deal with local construction templates and waste wooden pallets. The processing efficiency of the crushing equipment is very high, and the output can be as high as 10t/h.

In addition to quickly crushing wood materials, it also has the function of automatically separating wood chips and nails, which effectively guarantees the safety of workers.

Wood pallet recycling problem

Among all substitute wood pallets, wooden pallets have the most market potential. The demand for wood for wooden pallets has increased, which has led to the destruction of forest resources. Whether from the perspective of ecological environment protection or resource conservation, how to solve the wood pallets recycling problem is necessary. After being collected by wood recyclers, part of the recyclable pallet is repaired for reuse, and part is chopped.

Hot Product

Wood Sawdust Briquettes Production Line | Pini Kay Heat Logs Plant

The wood sawdust briquettes production line mainly extrudes…

Charcoal Grinder Machine for Making Fine Charcoal Powder

The lump charcoal grinder machine also known as…

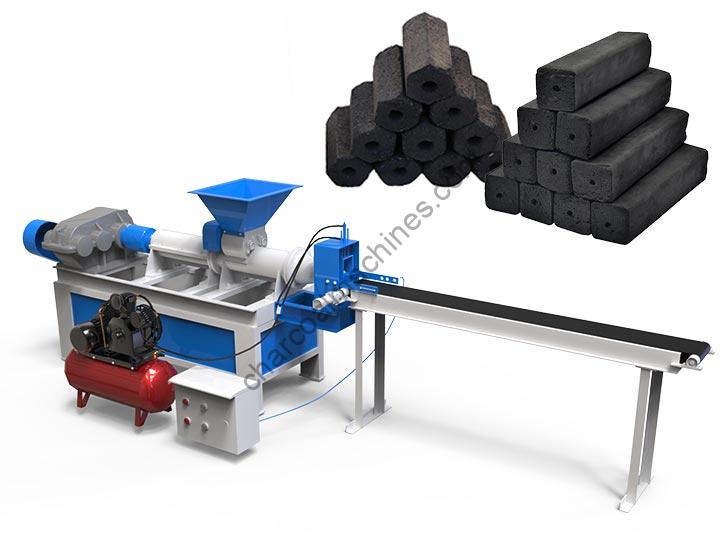

Charcoal Coal Briquettes Extruder Machine for Charcoal Plant

Charcoal briquette machine can extrude charcoal & coal…

Hookah Shisha Charcoal Production Line | Round & Cube Briquettes Making

The shisha hookah charcoal production line is designed…

Barbecue Charcoal Production Line | BBQ Briquettes Processing Plant

The barbecue charcoal production line mainly processes various…

Briquette Cutters for making briquette charcoal as required

The charcoal briquettes cutting machine is used to…

Raymond Mill for Grinding Fine Charcoal Powder

Raymond mill is mainly used as a piece…

Continuous Charcoal Furnace for Biomass Charcoal Production

Continuous carbonization furnace is a new type of…

Hookah Charcoal Machine to Make Round & Cube Shisha Charcoal

Shuliy shisha charcoal press machine is designed according to…

No Comments.