Barbecue Charcoal Production Line | BBQ Briquettes Processing Plant

Barbecue Charcoal Production Line | BBQ Briquettes Processing Plant

The barbecue charcoal production line mainly processes various types of charcoal balls. The BBQ charcoal briquettes processing plant can produce barbecue charcoal of various specifications and sizes. The industry’s barbecue charcoal production line is an automated BBQ briquettes processing line independently designed by the Shuliy factory.

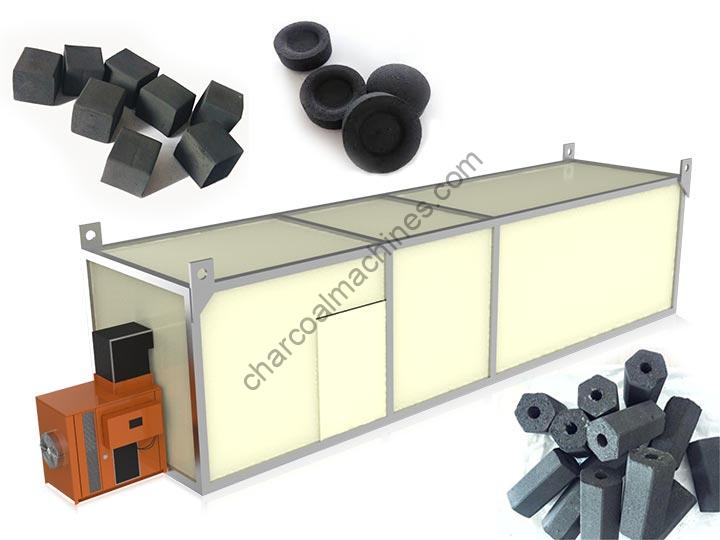

The production line mainly includes a continuous carbonization furnace, automatic conveyor, carbon crusher, screw conveyor, storage bin, screw conveyor, carbon powder crusher and mixer, binder mixer, continuous conveyor, BBQ charcoal briquettes press machine, briquettes dryer machine, and barbecue charcoal packaging machine.

Features of barbecue charcoal briquettes

There are many types of barbecue charcoal currently on the market: quick-burning charcoal, coconut shell charcoal, spherical barbecue charcoal, pillow-shaped bbq briquettes, and oval barbecue charcoal.

These different sizes and specifications of barbecue charcoal can be mass-produced with the help of the barbecue charcoal production line. The BBQ charcoal made by this processing line is easy to ignite, and it is smokeless and tasteless when burned. In addition, due to its high density, this barbecue charcoal has a high calorific value and a long burning time.

Main machine of the BBQ charcoal production line

| No. | Machine name |

| 1 | Continuous carbonization furnace |

| 2 | Charcoal crusher |

| 3 | Charcoal powder mixer |

| 4 | Binder mixer |

| 5 | Barbecue charcoal press machine |

| 6 | BBQ briquettes dryer |

| 7 | BBQ charcoal packaging machine |

Specifications of the 500kg/h barbecue charcoal production line

| Item | Specifications | Qty |

Continuous carbonization furnace  | Model: SL-800 Dimension: 9*2.6*2.9m Power: 22kw Capacity: 300-400 kg/h Weight: 9 ton Machine shell thickness(steel): 11mm Function: carbonize biomass materials into charcoal. | 1 |

Belt conveyor | Dimension: 5000*700*700mm Power: 2.2kw Function: transport charcoal blocks from continuous carbonization furnace to charcoal crusher machine. | 1 |

Charcoal crusher machine | Model: SL-C-600 Power: 22kw Dimension: 3600*1700*1400mm Capacity:500-600kg/h Final size: less than 5mm Function: crush charcoal blocks into charcoal powder, then they will be easy to shape. | 1 |

Screw conveyor | Dimension: 6.6m*0.3m*0.5m Power: 4kw Function: transport charcoal powder from charcoal crusher machine to silo. | 1 |

Storage bin | Power: 4kw Dimension: 2000*3000mm Function: store charcoal powder and balance the speed of the production line. | 1 |

Screw conveyor | Dimension: 6.6m*0.3m*0.5m Power: 4kw Function: transport charcoal powder from silo to wheel grinder machine. | 1 |

Wheel grinder machine | Model: SL-W-1300 Power: 5.5kw Capacity: 300-500kg/h Inner diameter:1300mm Function: combine the charcoal powder with binder and water fully, then they will be more sticky | 1 |

Binder mixer | Model: SL-M800 Input capacity: 0.6m³ Power: 3kw Inner diameter: 800mm Function: mix binder and water. | 1 |

Belt conveyor | Dimension: 5000*700*700mm Power: 2.2kw Function: transport charcoal powder from wheel grinder machine to charcoal ball press machine. | 1 |

Charcoal ball press machine | Power: 5.5kw Capacity: 1-2 t/h Pressure: 50tons per time Weight: 720kg Function: press charcoal powder into charcoal balls | 1 |

Packing machine | Packing weight: 20-50kg per bag Packing speed: 300-400 bags per hour Power: 1.7kw Dimension: 3000*1150*2550mm | 1 |

Note of BBQ charcoal processing plant specification parameters

- The processing capacity of the barbecue charcoal production line can be customized between 500kg/h and 20t/h. Our factory can formulate the most cost-effective barbecue charcoal processing plan for customers according to their specific processing needs and investment budget.

- The main processing process of the barbecue charcoal processing plant is carbonization, char pulverization, charcoal powder stirring, charcoal powder forming, charcoal block drying, and charcoal block packaging. For factories and customers who need continuous production, they usually need to buy a barbecue charcoal dryer to shorten the drying time of charcoal briquettes. However, small charcoal processing plants or areas with long sunshine hours do not need to buy a dryer, but use natural drying to dry the barbecue charcoal.

- Any equipment in the barbecue charcoal processing line has different models to choose from. We can also customize the most suitable machine model for customers according to the size and shape of the customer’s factory.

- Barbecue charcoal molding machine, that is, the extruding die of charcoal ball press machine can be replaced. Therefore, the molding machine can process BBQ charcoal briquettes of different sizes and shapes, such as pillow-shaped, spherical, oval, Rhombus, lettering pattern, etc.

Hot Product

Continuous Dryer for Drying Sawdust & Rice Husk

Industrial sawdust dryers and rice husk drying machines…

Hookah Charcoal Machine to Make Round & Cube Shisha Charcoal

Shuliy shisha charcoal press machine is designed according to…

Wood Shaving Machine for Animal Bedding

The wood shaving machine can process logs and…

Wood Sawdust Briquettes Production Line | Pini Kay Heat Logs Plant

The wood sawdust briquettes production line mainly extrudes…

Batch Charcoal Drying Machine with Good Performance

The charcoal dryer machine is mainly used to…

Thermal Shrink Packing Machine for Packaging Sawdust Pini Kay Briquettes

This automatic thermal shrink packing machine can be…

Honeycomb Coal Briquette Press Machine

The honeycomb coal briquette machine can press the pulverized charcoal powder…

Continuous Charcoal Furnace for Biomass Charcoal Production

Continuous carbonization furnace is a new type of…

Briquette Press for Making Sawdust Briquettes from Biomass Wastes

The industrial sawdust briquette machine is mainly used to…

6 comments