Compressed Wooden Pallet Production Line

The compressed wooden pallet production line is a complete industrial processing line for processing high-density wood pallets. The production process of this wooden pallet production line mainly includes sawdust making, sawdust drying, sawdust and glue mixing, and wooden pallet pressing.

This molded wooden pallet processing plant is very suitable for large and medium-sized wooden pallet factories, with the advantages of simple operation, large output, and easy maintenance. At present, our compressed wood pallet equipment has been exported to the United States, France, Poland, Chile, Canada, Germany, Serbia, Greece, Saudi Arabia, Russia, South Africa, and other countries.

Why choose to start a compressed wood pallet business?

Compressed wooden pallets are an important auxiliary tool in international transportation. Especially in the shipment of goods, the role of wooden pallets is very prominent. Compared with ordinary spliced wooden pallets, compressed wooden pallets have a higher load-bearing capacity and longer service life. Therefore, compressed wooden pallets are in great demand.

Starting a wooden pallet production business by purchasing a complete compressed wooden pallet production line has become the choice of many investors. Compressed wooden pallet factories can usually produce wooden pallets of different sizes and specifications to meet different international cargo transportation requirements.

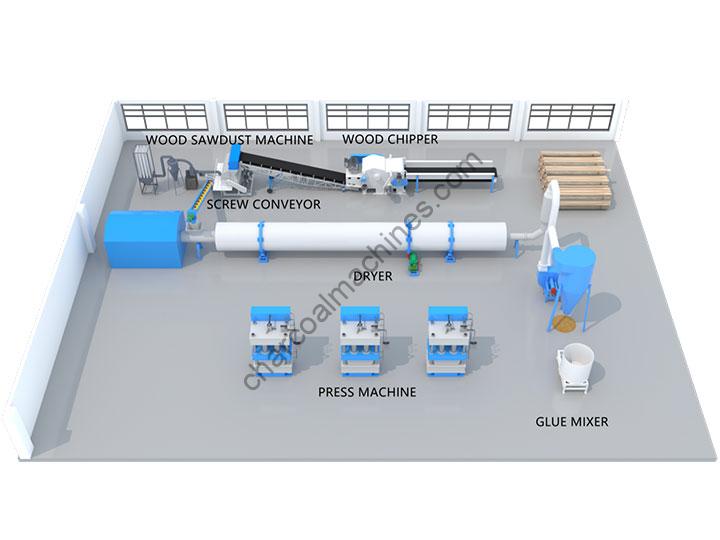

Components of compressed wooden pallet production line

The main equipment of the wooden pallet production line is composed of a wood crusher, sawdust dryer, mixer, and hydraulic wooden pallet machine. This processing line enables the transformation from wood to compressed wood pallets.

Wood crusher for making sawdust

The raw materials for processing compressed wooden pallets are usually various biomass materials, such as straw, rice husks, coconut fibers, logs, branches, tree roots, waste wooden furniture, waste wood boards, etc. We need to use a wood shredder to pulverize these raw materials to the fineness of raw materials suitable for processing wooden pallets. The size of sawdust required for processing wooden pallets is generally between 3-5mm. The crushing fineness of the wood crusher can be adjusted according to customer needs.

Rotary dryer for drying sawdust

Both straw and wood have different moisture content. In order to ensure the quality of compressed wooden pallets, we need to control the moisture content of the raw materials. When the sawdust is processed, we need to use a tumble dryer to continuously dry the sawdust to keep its moisture content below 15%. If the moisture content of the raw material is too high, the processed wooden pallet will have a rough surface, low density, and unevenness.

Mixer machine for glue and sawdust mixing

This electric mixer can quickly mix sawdust and a certain proportion of glue evenly. The purpose of adding urea-formaldehyde resin glue to the sawdust is to increase the cohesion of the sawdust so that the compressed wood pallet has a higher density.

Wooden pallet press machine for making pallets

This hydraulic wood pallet machine can extrude sawdust in a mold under high temperature and high-pressure conditions. The hydraulic pressure of this machine varies according to different models. Generally, the larger the model of the machine, the greater its hydraulic pressure and the greater the output. In addition, the molds of the wooden pallet press machine can be changed to different shapes and sizes.

Finished wood pallets display

The size, specification, pattern, and thickness of the finished wooden pallet are all determined by the mold of the wooden pallet press and the pressure of the machine. We can customize a suitable wooden pallet production plan according to the needs of customers.

Hot Product

Small Feed Pellet Machine for Making Animal Feeds

The small feed pellet machine is the home…

Latest Charcoal Making Machine to Make Biocharcoal

The newest charcoal making machine is the ideal…

Wood Crusher for Making Sawdust from All Wood Wastes

Wood crushers are commonly used shredding equipment for…

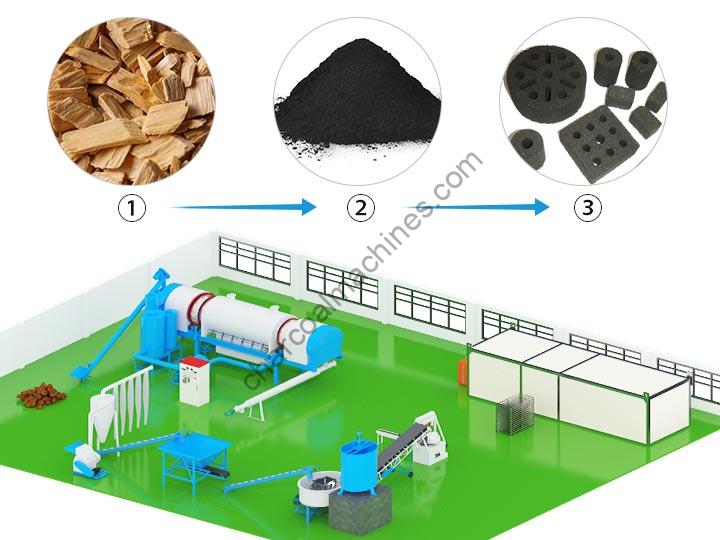

Barbecue Charcoal Production Line | BBQ Briquettes Processing Plant

The barbecue charcoal production line mainly processes various…

Briquette Cutters for making briquette charcoal as required

The charcoal briquettes cutting machine is used to…

Saw Mill Machine for Processing Lumbers

Industrial wood sawmill machines can saw logs into…

Drum Wood Chipper for Wood Chips Mass Production

The wood chipper shredder machine mainly can be…

Honeycomb Coal Briquette Production Line | Briquettes Charcoal Processing Plant

The honeycomb coal briquette production line can turn…

Wood Debarker Machine for Peeling Logs

Wood debarker machine, also known as the log…

No Comments.