Máquina industrial de pellets de madera en venta

La extrusora de pellets de madera es un equipo especializado diseñado para convertir madera cruda en pellets de combustible de alta densidad. Esta pelletizadora está diseñada para una fiabilidad y eficiencia operativa, produciendo pellets uniformes de manera constante.

Máquina industrial de pellets de madera en venta

La extrusora de pellets de madera es un equipo especializado diseñado para convertir madera cruda en pellets de combustible de alta densidad. Esta pelletizadora está diseñada para una fiabilidad y eficiencia operativa, produciendo pellets uniformes de manera constante.

Características Destacadas

¿Buscas una máquina de pellets de madera confiable para convertir residuos biomásicos como aserrín, astillas de madera y paja en combustible de alto valor? Como fabricante líder, ofrecemos una gama completa de fabricantes de pellets de madera — desde modelos pequeños para uso doméstico hasta molinos de pellets de madera industriales pesados para producción en masa. Transforma tus residuos en ganancias y solicita una cotización personalizada hoy.

OBTÉN UNA COTIZACIÓN GRATUITA AHORA

¿Qué es una máquina de pellets de madera y cómo funciona?

Una máquina de pellets de madera (también conocida como fabricante de pellets de madera o pelletizadora de biomasa) está diseñada para comprimir materiales de biomasa de baja densidad en pellets de combustible sólido de alta densidad. Procesa eficientemente cultivos, residuos forestales, aserrín y astillas de madera en un combustible granular con alta gravedad específica y textura dura.

Los pellets de madera biomasa finales tienen excelentes características: son fáciles de encender, poseen un alto valor calorífico y producen muy poca ceniza después de la combustión. Esto los convierte en un combustible limpio, sanitario y de alta calidad que puede reemplazar al carbón en calderas industriales y domésticas, así como para cocina y calefacción civiles.

El proceso de trabajo

Cuando la pelletizadora de madera está en funcionamiento, el proceso es el siguiente:

- Alimentación: Materias primas (como aserrín de un trituradora de madera) caen verticalmente desde la entrada de alimentación y se distribuyen uniformemente en la superficie del molde mediante una rueda de prensado rotatoria.

- Prensado y Formación: El material se fuerza continuamente a través de los agujeros del dado por la inmensa presión de los rodillos. Durante este proceso, el material está sometido a alta presión y alta temperatura, causando cambios físicos y químicos que activan la lignina natural de la madera para actuar como aglutinante.

- Corte y Descarga: Un cuerpo sólido y cilíndrico se extruye continuamente de los agujeros del dado. Luego, un cortador interno corta estos cilindros en pellets uniformes, que se descargan por la salida, completando el proceso de pelletización.

Vea nuestra máquina de extrusión de pellets en acción

Vea todo el proceso de fabricación de pellets de madera desde la materia prima hasta el producto terminado.

¿Qué máquina de pellets de madera es la adecuada para ti? (Modelos y aplicaciones)

Elegir la máquina adecuada depende completamente de tus objetivos de producción. Ofrecemos modelos para cada escala de operación.

1. Pequeña máquina de pellets de madera para uso doméstico

Ideal para pequeñas granjas, talleres o propietarios que desean producir su propio combustible para estufas de pellets. Estas compactas fabricantes de pellets de madera son fáciles de operar y requieren poco espacio.

- Capacidad: 50 – 300 kg/h

- Ideal para: Producción de combustible DIY, pellets caseros, alimentación animal a pequeña escala.

2. Máquina comercial de pellets de madera

Diseñado para pequeñas y medianas empresas que desean vender pellets de madera localmente o usarlos en calderas comerciales. Estas máquinas ofrecen un excelente equilibrio entre producción e inversión.

- Capacidad: 300 – 800 kg/h

- Ideal para: Negocio de venta de pellets, grandes granjas, pequeñas fábricas.

3. Molino de pellets de madera industrial y línea de producción

Para fabricación a gran escala, nuestros molinos industriales de pellets de madera son el núcleo de una línea completa de producción de pellets de madera. Estos sistemas robustos están diseñados para operar las 24 horas del día, los 7 días de la semana, y para una alta producción.

- Capacidad: 1 – 5 toneladas/hora (o más)

- Ideal para: Producción en masa para exportación, plantas de biocombustibles.

Especificaciones técnicas

| Modelo | Capacidad (t/h) | Potencia (kW) | Diámetro del pellet (mm) | Materias primas aplicables |

|---|---|---|---|---|

| ZLSP-200 (Pequeña) | 0.1 – 0.2 | 7.5 | 6, 8, 10 | Aserrín, paja, cáscara de arroz |

| ZLSP-400 (Comercial) | 0.4 – 0.6 | 30 | 6, 8, 10 | Astillas de madera, aserrín, corteza |

| MZLH-520 (Industrial) | 1.5 – 2.5 | 132 | 6, 8, 10 | Todos los biomateriales, incluyendo madera dura |

Nota: Las especificaciones son referenciales. Ofrecemos soluciones personalizadas.

Precio de la máquina de pellets de madera

El precio de una máquina de pellets de madera puede variar desde $2,000 para un modelo pequeño de uso doméstico hasta más de $100,000 para una línea de producción industrial completa. El costo final de la máquina de pellets de madera depende de la capacidad, la marca del motor y si necesita equipos auxiliares como trituradora, secador, enfriador y empacador. Contáctenos para una cotización precisa y sin compromiso adaptada a sus necesidades.

Características principales y ventajas

- Bajo consumo de energía, alta producción: Con una fuente de energía optimizada (por ejemplo, 80KW para una máquina de 1-1.5 toneladas/h), nuestros diseños reducen el consumo de energía en un 10-20% en comparación con productos similares, maximizando su rentabilidad.

- Bajo costo laboral y alta eficiencia: Un solo conjunto de equipos requiere solo 2-3 personas desde la producción hasta el embalaje. Las máquinas están diseñadas para una operación y mantenimiento sencillos, minimizando el tiempo de inactividad.

- Producción ecológica: El diseño interno cuenta con un sistema de eliminación de polvo integrado, asegurando bajo nivel de ruido y sin emisiones de humo o aguas residuales durante el proceso de producción.

- Duradera y ampliamente aplicable: Nuestras máquinas tienen una baja tasa de desgaste durante su uso y un tamaño reducido, lo que las hace adecuadas tanto para sitios de producción urbanos como rurales.

- Éxito global comprobado: Hemos instalado con éxito más de 500 líneas de pellets en más de 30 países, incluyendo Canadá, EE. UU. y Malasia.

Estructura detallada de la máquina

Nuestra máquina vertical de pellets de madera tiene una estructura compacta y una apariencia atractiva, facilitando su traslado en el sitio de trabajo. Está compuesta por una base de máquina de pellets, una caja de reducción grande, una sala de rodamientos, una capucha de alimentación, una parte de descarga, un motor, un conjunto de rodillo de presión y un dado. El motor eléctrico está conectado directamente al eje del reductor. Después de un cambio de dirección de 90°, el motor impulsa un husillo vertical, que a su vez hace rodar el rodillo a lo largo de la superficie interior del dado para completar el proceso de prensado.

Consejos de mantenimiento de la máquina de pellets de madera

- Durante la producción, engrase el rodillo de presión cada 2 horas usando un rodillo manual en el extremo del eje principal.

- Antes de cada sesión de trabajo, llene los rodamientos del tornillo y del agitador con lubricante No. 2.

- Llene el reductor de agitación de la máquina con grasa de disulfuro de molibdeno a base de litio cada seis meses.

- Los rodamientos del tornillo y los ejes del agitador deben limpiarse y cambiarse el aceite cada dos años.

- Para almacenamiento a largo plazo, prensa materiales oleosos y no deteriorables a través de la máquina para llenar los orificios del molde. Limpie todas las partes de residuos de material y cubra la máquina con una cubierta de plástico.

Preguntas frecuentes (FAQ)

¿Qué materias primas se pueden usar?

Nuestros equipos pueden procesar una amplia gama de biomasa, incluyendo aserrín, virutas de madera, astillas, paja, cáscaras de arroz, cáscaras de cacahuete y más. El contenido de humedad ideal es del 12-18%.

¿Cuánto cuesta una máquina para fabricar pellets de madera?

Como se mencionó, los precios varían mucho. Una máquina pequeña comienza alrededor de $2,000, mientras que las líneas industriales son una inversión significativa. Contáctenos con sus requisitos de materia prima y capacidad para obtener un precio preciso.

¿Tiene máquinas de pellets de madera en venta en Canadá?

Sí, realizamos envíos a todo el mundo, incluyendo Canadá. Tenemos varios clientes en Columbia Británica y Ontario y podemos gestionar toda la logística y el despacho de aduanas para su pedido.

¿Cuál es el proceso completo de fabricación de pellets de madera?

Una línea de producción completa generalmente incluye: Trituración/Desmenuzado → Secado → Pelletizado → Enfriamiento → Tamizado → Embalaje.

¿Listo para comenzar tu negocio de pellets?

Nuestros expertos están listos para ayudarte a elegir la máquina perfecta y proporcionar una cotización detallada. Contáctanos vía chat en línea o correo electrónico para comenzar tu proyecto.

Producto Caliente

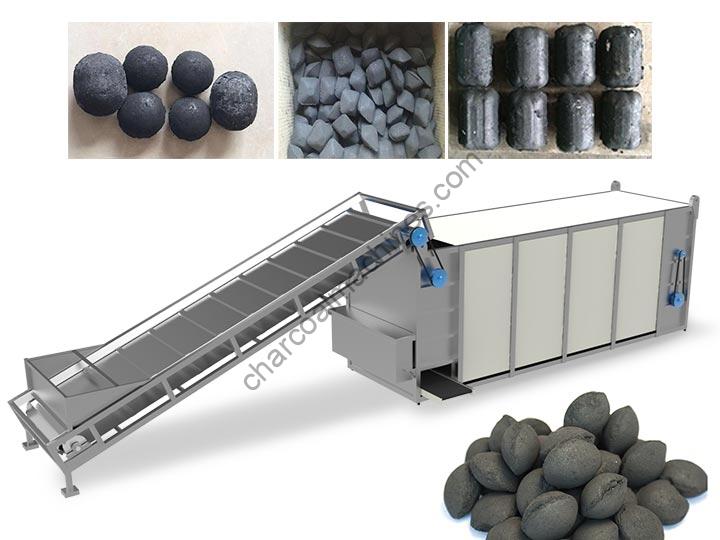

Secador de banda de malla para secar briquetas de forma continua

El secador de cinta de malla es una pieza de…

Trituradora de madera para hacer aserrín de todos los residuos de madera

Los trituradores de madera son equipos de trituración comúnmente utilizados para…

Línea de producción de carbón de shisha redondo y en cubo | Fabricación de briquetas redondas y en cubo

La línea de producción de carbón de shisha se diseña…

Trituradora de carbón | Molino de polvo de carbón

La máquina trituradora de carbón puede pulverizar principalmente diversos…

Chipeadora de tambor para producción masiva de astillas de madera

La máquina trituradora de madera puede ser…

Máquina y línea de producción de carbón vegetal para hacer biocarbón

Las máquinas de fabricación de carbón pueden convertir residuos de biomasa,…

Máquina de aserrado para procesamiento de tablas

Las máquinas industriales de aserradero pueden cortar troncos en…

Máquina de embalaje de contracción térmica para empaquetar briquetas de aserrín Pini Kay

Esta máquina automática de empaquetado térmico retráctil puede ser…

Máquina de palets de madera comprimida para la producción de palets moldeados

La máquina de palets de madera comprimida es una pieza…

4 comentarios