Wood Shaving Machine for Animal Bedding

Wood shavings machine | Log shavings mill

Wood Shaving Machine for Animal Bedding

Wood shavings machine | Log shavings mill

Features at a Glance

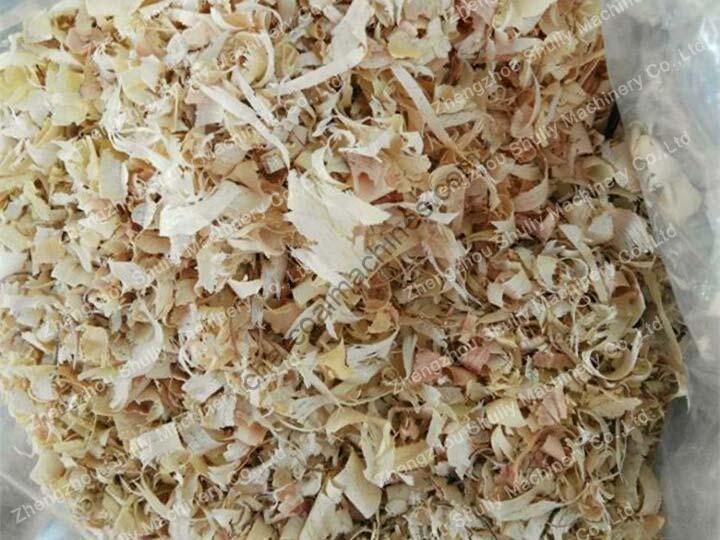

The commercial wood shaving machine can process logs and various types of wood into wood shavings of various sizes. The high-quality wood shavings processed by the wood shaving mill can be used for animal bedding, such as chickens, pigs, horses, and various pets. The size and thickness of wood shavings can be adjusted according to user needs. Until now, we Shuliy factory has exported thousands of wood shaving machines to South Africa, Ghana, Turkey, Iran, America, Canada, Singapore, Thailand, and other countries.

The electric wood shaving machine is also a kind of wood crushing equipment, which is widely used for making wood shavings with even thickness. Especially for mass production of wood shavings in an automatic way.

This kind of small wood shaving mill can be used to make wood shavings from all kinds of wood chips, logs, small wood strips, tree branches, woodblocks, waste wood cutting materials, and furniture factory leftover materials. The wood shavings produced by the wood shaver are uniform in shape, uniform in thickness, and complete in specification.

Wood shaving mill’s application scope

The wood shavings made from the wood shaving mill can be used to make particleboard (plywood) and they are important materials for making furniture. Wood shavings can also be used as raw materials for wood pulp paper in paper mills.

In addition, in logistics transportation, some shavings can be added as a filler in some fragile goods to prevent damage. Shavings are widely used in poultry farms as animal litter fillers, so wood shavings are particularly suitable for pet litter and horse bedding. In addition, wood shavings can also be used as bioenergy ignition material.

Structure of the industrial wood shavings machine

Wood shaving machines can be equipped with low-voltage or high-voltage motors according to the customer’s production needs.

Large wood shaving machines have two methods of driving: belt drive and direct drive. Its feeding method can be divided into horizontal feeding and inclined feeding.

There are two ways of discharging: upper discharging and lower discharging. The output of wood shaving machines is 2 ~ 160 cubic meters per hour.

The commercial facility can be divided into two types: ordinary machines (4-6 knives) and multi-shaving shaving machines (8-6 knives).

Wood shaving equipment- working principle

The shaving machine has a very simple structure so that it is easy to install and operate. The main structure includes a frame, housing, cutter disk, pulley, inlet, outlet, and motor.

The need for a special note is that the entry of the equipment is inclined shaped so that we can put the branches and wood materials easily into the machine inside.

Besides, the outlet of the shaving machine is also downward sloping so that it can discharge the shavings quickly. When we put the wood or logs into the inlet of the wood shaving machine, the inside cutter disk and the blades will crush and shave the materials into shavings. The cutter disk can be adjusted according to different requirements of the shavings’ thickness.

Notes: for making high-quality wood shavings, we can peel the logs with a wood debarker machine first. Then we use the wood shaving machine to make shavings from the peeled logs.

How does the electric wood shavings machine work?

The wood shaving machine is a device that can automatically crush and process wood into shavings. After the raw material enters the feed port, it is cut into the crushing chamber by the blade.

It is further crushed under the impact of a high-speed rotating hammer blade and the action of a shearing knife, and then the wind generated by the built-in blades is sent out through the screen or through an external fan.

The size of wood shavings is determined by adjusting the length of the blade and the size of the screen aperture. The wearing part of this wood processing machine is the cutting blades.

Advantages of the Shuliy wood shaving machine

- The machine is capable of logs, branches, and board edges processed into shavings produced for the furniture factory.

- The wood shavings’ size is determined by adjusting the blade length to accommodate a variety of needs.

- Automatic self-feeding equipment has greatly increased production speed, it also saves time and manpower.

- The wood shavings’ power system can be designed with both the motor and the diesel engine.

- High working efficiency and the thickness of the wood shavings are adjustable.

Technical parameters of commercial wood shaving mill

| Model | Output | Feeding size |

| SL-S420 | 200kg/h | 6cm |

| SL-S600 | 500kg/h | 12cm |

| SL-S800 | 800kg/h | 16cm |

| SL-S1200 | 1.5t/h | 24cm |

| SL-S1500 | 2t/h | 32cm |

How is the wood shaving machine price?

The price of wood shaving machines varies with different configurations. In order to meet the needs of different shaving factories, the wood shaving equipment manufactured by our factory has many different models and processing capacities.

In addition, the power mode of the wood shaving machine has two options: electric motor and diesel engine. Typically, the larger the model of the wood shaving mill, the larger its output and the higher the price page. In addition, the price of wood shaving machines for different applications is slightly different.

Hot Product

Barbecue Charcoal Production Line | BBQ Briquettes Processing Plant

The barbecue charcoal production line mainly processes various…

Raymond Mill for Grinding Fine Charcoal Powder

Raymond mill is mainly used as a piece…

Compressed Wood Pallet Machine for Molded Pallet Production

The compressed wood pallet machine is a piece…

Vertical Carbonization Furnace For hardwood Charcoal Production

The airflow hoisting carbonization furnace is currently the…

Shisha (Hookah) Charcoal Production Line | Briquette Packaging Dryer Plant

The automatic shisha(hookah) charcoal production line is the…

Continuous Dryer for Drying Sawdust & Rice Husk

Industrial sawdust dryers and rice husk drying machines…

Hookah Charcoal Machine to Make Round & Cube Shisha Charcoal

Shuliy shisha charcoal press machine is designed according to…

Round & Pillow Barbecue Charcoal Ball Press Machine

Barbecue charcoal press machine can make compressed charcoal…

Wood Debarker Machine for Peeling Logs

Wood debarker machine, also known as the log…

26 comments