Wood Hammer Mill for Recycling Wood Scraps

Wood hammer crusher mill | Straw grinding machine

Wood Hammer Mill for Recycling Wood Scraps

Wood hammer crusher mill | Straw grinding machine

Wood hammer crusher mill, also known as a wood straw grinding machine, is to crush wood chips, straw, waste paper, coconut shell, etc. through a hammer, and then filter through a screen to finally produce sawdust of uniform size. The industrial hammer mill can use diesel engines or electric motors to generate electricity. Our factory can customize the feed inlet, machine size, whether to add wheels, dust removal device, etc. according to the customer’s raw materials and output. Welcome to inquire.

Brief description of the wood hammer crusher mill

A straw grinding machine is one of the wood processing equipment. This product is an advanced fine crushing equipment that can crush all kinds of raw materials, such as rice straw, wheat straw, corn stalks, beanstalks, hay, coconut shells, wood chips, etc. This series of pulverizers are simple in structure, high in production efficiency, and easy to operate. They are suitable for farms, livestock farms, and wood processing plants. In addition, this machine can also crush Chinese medicinal materials, quartz stone, coal and dry coal stone, wood, and industrial raw materials. Our factory can customize models according to the size of crushed raw materials and the actual situation of customers.

Raw material of the straw grinding machine

The wood hammer crusher mill is suitable for the crushing and recycling of a variety of materials. Crushable materials include waste paper, coconut shells, waste wood chips, etc. The resulting sawdust can be used as a particle board to synthesize wooden furniture.

The crusher can also crush and process high-fiber materials such as rice straw, wheat straw, corn stalks, and sorghum stalks. In addition, this machine can also crush Chinese medicinal materials, quartz stone, coal and coal dry stone, wood, herbs, and industrial raw materials.

Wood crusher machine structure

The wood hammer crusher mill is composed of a feed inlet, a hammer, a screen, a gasket, and a discharge outlet. Among them, the hammer will rotate at a high speed to break the raw materials, and the number of hammers is different for different machine models. Gaskets are used to protect the casing of the machine and to extend the life of the machine.

Related equipment of the straw grinding machine

The machine is commonly equipped with dust removal devices, conveying devices, fans, motors, diesel engines, or large diesel units. When the model is large, an electric control cabinet can be configured to ensure stable and safe power consumption.

Principle of the industrial hammer mill

After the material enters the crushing chamber from the feed hopper, it is crushed by the impact of the high-speed rotating hammer. Driven by the airflow, the sawdust is continuously hammered along the outer edge of the rotor. The raw materials are quickly crushed after being hit, collided, and rubbed. The pulverized powder particles are subjected to the centrifugal pressure of the rotor and the suction force of the fan to pass through the sieve holes and then are transported to the storage bag or storage bin.

Features of the straw grinding machine

Wood hammer crusher mill can be designed and customized.

- If the customer needs to crush larger branches and tree trunks, the machine can additionally add a large feed inlet.

- The machine can be customized with wheels for easy movement in the processing plant or forest farm.

Various power modes are available

- Diesel engine. There are small diesel engines and large diesel units that are used with different types of machines.

- The motor generates electricity.

Industrial hammer mill machine parameters

| Type | Power (kw) | Capacity (t/h) | Number of hammers (piece) |

| SL-H60 | 22 | 0.6-0.8 | 30 |

| SL-H70 | 30 | 1-1.2 | 40 |

| SL-H80 | 37 | 1.2-1.5 | 50 |

| SL-H90 | 55 | 1.5-3 | 50 |

| SL-H1000 | 75 | 3-4 | 105 |

| SL-H1300 | 90 | 4-5 | 105 |

Video of the wood hammer crusher mill

Different customized straw grinding machine display

Maintenance of the wood hammer crusher mill

- The main wearing parts of this series of models are hammer blades, which are manufactured by special technology. When the edges and corners of the blades are blunt, the edges and corners of the blades can be changed or turned for use, or replaced with new ones. The replacement must be carried out in a complete set, and the self-made or unreliable rotary vanes should be paid more attention to. Otherwise, it will cause severe vibration of the host, affect production, and accelerate the damage and service life of the bearing.

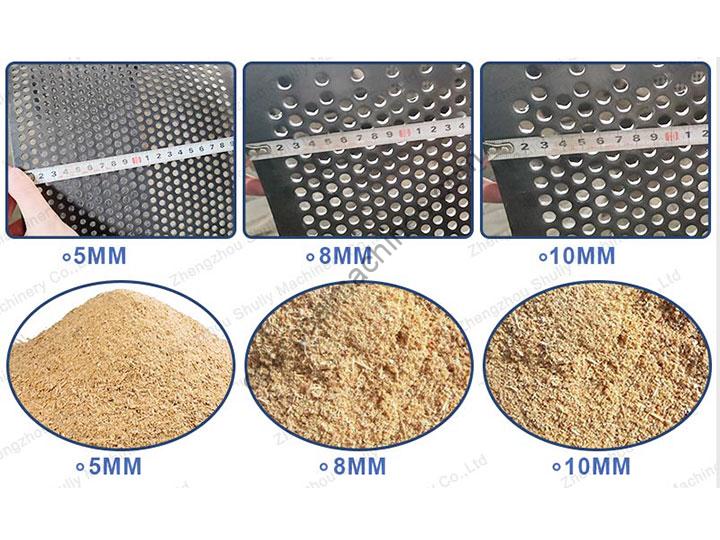

- The sieve of vulnerable parts uses its aperture to control the thickness. The factory supplies a variety of screens with different specifications from 0.6 to 12mm, and users can purchase them according to their needs. When replacing, pull out the sieve and install a new sieve (light side down). The blade of the straw grinding machine is a vulnerable part, do not put hard metals, stones, etc. into the material opening to prevent damage to the blade.

- Grease the bearing regularly.

- Collision is strictly prohibited. The long-term shutdown should be cleaned inside and outside and kept properly to prevent rust.

Loading and shipping the wood hammer crusher mill

Hot Product

Charcoal Briquettes Packaging Machine for Packing Barbecue Charcoal Quantitatively

This quantitative charcoal briquettes packaging machine can be…

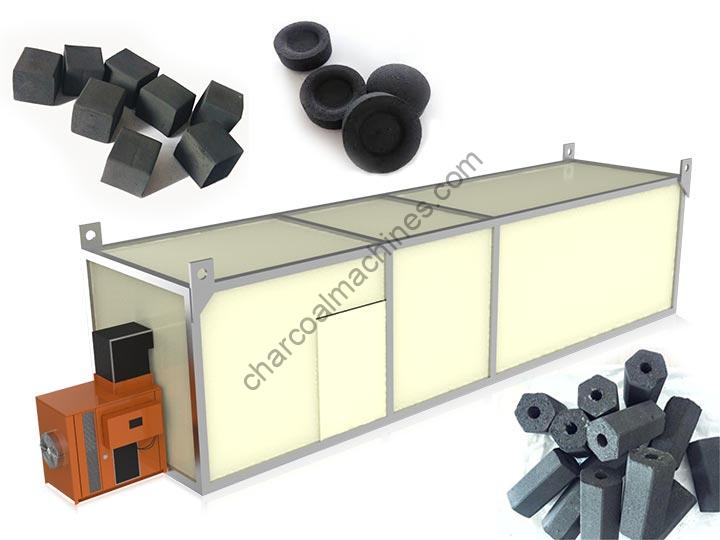

Barbecue Charcoal Production Line | BBQ Briquettes Processing Plant

The barbecue charcoal production line mainly processes various…

Batch Charcoal Drying Machine with Good Performance

The charcoal dryer machine is mainly used to…

Drum Wood Chipper for Wood Chips Mass Production

The wood chipper shredder machine mainly can be…

Horizontal Charcoal Furnace For Biochar Carbonization

The horizontal charcoal furnace is the high efficient…

Disc Wood Chipper for Household Use

The small disc wood chipper can process logs,…

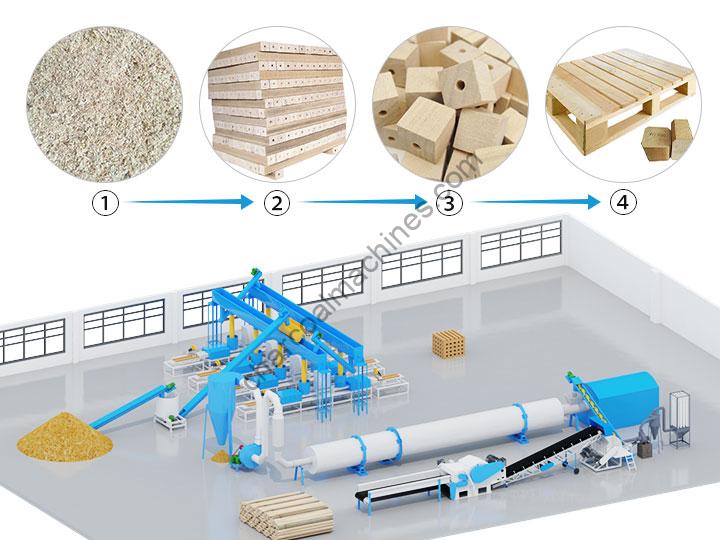

Wood Block Production Line for Making Compressed Wood Pallet blocks

Wood block production line can process high-quality compressed…

Charcoal Grinder Machine for Making Fine Charcoal Powder

The lump charcoal grinder machine also known as…

Wood Powder Grinder Machine for Making Wood Flour

The wood powder machine is used for the…

No Comments.