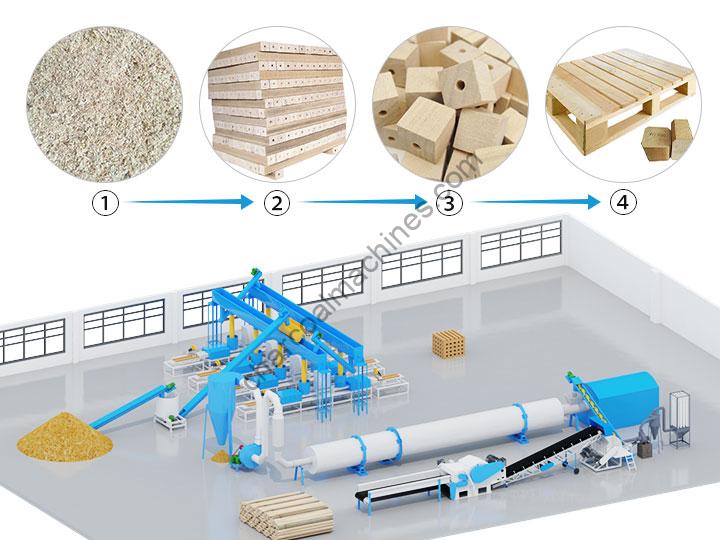

Wood Block Production Line for Making Compressed Wood Pallet blocks

Wood Block Production Line for Making Compressed Wood Pallet blocks

Wood block production line can process high-quality compressed sawdust blocks for wood pallets processing. The production process of the compressed wood block production line mainly includes wood crushing, sawdust drying, sawdust mixing, wood block extrusion molding, wood block cutting, etc.

Using sawdust block machines, we can recycle a large amount of sawdust, wood shavings, and various biomass raw materials to produce high-value-added wooden blocks. At present, many foreign customers have ordered our full set of wood block making machines to carry out pallets processing business, such as the United States, Mexico, Argentina, Malaysia, New Zealand, Ghana, South Africa, Iran, Saudi Arabia, Romania, Germany, Belgium, Finland, Russia, etc.

What are wood pallet blocks?

Wood pallet blocks are wooden blocks compressed under high temperature and high-pressure conditions. Because the wooden block is made under huge pressure, their density and hardness are very high, it is not easy to be deformed and worn by moisture, and has a long service life.

This kind of wood block is often used for further assembly to wooden pallets, as a supporting angle of wooden pallets. The number of wood blocks required for wooden pallets of different specifications is different. In addition, wood blocks are also used to process various wooden crafts, building blocks, furniture, etc.

What can be used for making compressed pallet blocks?

The raw materials used to produce compressed blocks are plentiful and cheap, such as sawdust, rice husk, wood shavings, branches, roots, wood scraps, straw, coconut fiber, waste wooden furniture, waste wooden pallets, waste wood boards, etc.

Before processing wooden blocks, we need to use a shredder to crush these raw materials into sawdust with a size of less than 5mm. In addition, if the humidity of the sawdust is high, we need to use a sawdust dryer to dry it so that the moisture content does not exceed 15%.

Complete wood block production line components

Whether it is a small pallet blocks processing plant or a large wooden pallet factory, the equipment required to process compressed wood blocks is basically the same, but the output of the required equipment is different. A complete wood block production line usually includes a drum wood chipper, a hammer mill, a continuous sawdust dryer, a sawdust mixer, and one or more wood block extruder machines (depending on the customers’ processing output), one or more wood block cutting machines.

Machine list for making wood block

Drum wood chipper

This continuous wood chipper can quickly cut large-sized logs, branches, wood scraps, waste wood boards, etc. into wood chips or chips. It is characterized by high crushing efficiency, large output, and simple operation. The output of this drum wood chipper is generally between 1t/h and 5t/h.

Wood chips shredder machine

This hammer mill can quickly crush the wood chips processed by the drum chipper into sawdust. The pulverizer utilizes the striking principle of the hammer blade during high-speed operation to pulverize sawdust, straw, etc. into very fine sawdust. It is characterized by large output and no dust pollution. The pulverizer is equipped with a dust removal device, which can collect sawdust without causing dust pollution.

Sawdust dryer machine

The tumble dryer continuously dries sawdust and rice husks with high moisture content. The heat source of this continuous dryer can be coal, charcoal, biomass pellets, wood, etc. The sawdust dryer is equipped with a dust removal device, which can gather the dried sawdust to avoid smoke and dust pollution.

Sawdust glue mixer

We use this automatic mixer to mix the sawdust and urea-formaldehyde resin glue evenly according to a certain ratio. Then put the mixed sawdust into the pallet blocks molding machine for extrusion.

Sawdust blocks extruder machine

This kind of wood block machine usually consists of two sets of symmetrical extrusion devices, which can extrude sawdust from two outlets respectively to make wood blocks with higher density. The power of the machine is the motor, and the feeding can be made by screw Conveyor automatic feeding or manual feeding. The forming mold at the outlet of the machine can be replaced to process pallet blocks of different sizes.

Wood block cutting machine

At the discharge port of the pallet block press machine, we can install matching wood block cutters. This automatic cutting machine is controlled by an infrared sensor device, which can automatically sense the set cutting length and cut.

Optional independent wood block cutting machine

In order to further cut the wooden blocks, we can use the CNC pallet block cutting machine to cut the long wood blocks into cubes of the same size. Of course, the cutting size can be set as required.

Main features of the Shuliy wood block production line

- Shuliy factory can provide customers with cost-effective compressed pallet blocks processing solutions according to their production needs and investment budget. The finished size and output of this wood block production line can be customized.

- Our factory supports customers to visit the factory and test the wood pallet block equipment in person. In addition, for customers who cannot visit the factory, we also support online factory visits, that is, through video calls and live broadcasts in the factory to satisfy customers’ understanding of the machine.

- Our factory engineers can design drawings for equipment installation for customers according to factors such as the customer’s factory area, location, and shape. It is also possible to modify the voltage of the device. For customers who need it, we can send engineers to the customer’s country to guide the installation and operation of wood block machines.

Customer cases of wood block production lines

In the past 5 years, the compressed wood block making machines of our Shuliy factory have been installed and used in more than 40 countries and regions. In the past year, our factory’s pallet block plants have been mainly exported to Mexico, the United States, Brazil, Indonesia, Australia, Somalia, Ghana, Greece, Romania, Saudi Arabia, and other countries.

Hot Product

Comprehensive Pallet Crusher for Shredding Wood Wastes

The comprehensive pallet crusher, namely the scrap wood…

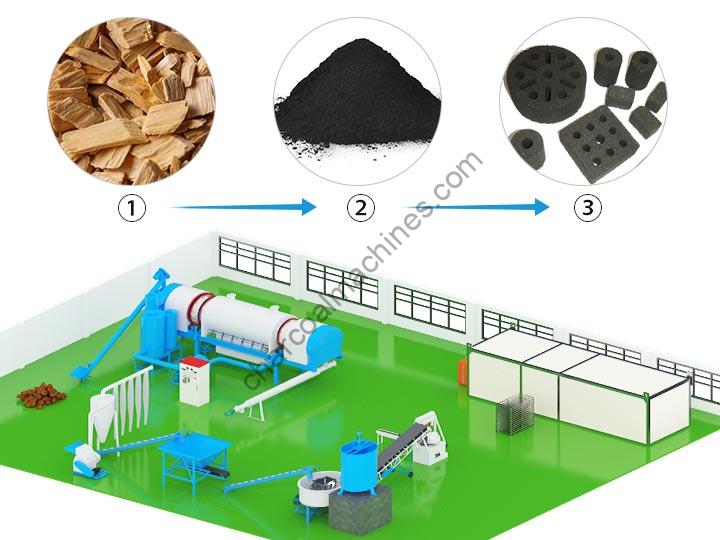

Barbecue Charcoal Production Line | BBQ Briquettes Processing Plant

The barbecue charcoal production line mainly processes various…

Charcoal Making Machine: The Ultimate Guide to High-ROI Biochar Production

The newest charcoal making machine is the ideal…

Vertical Carbonization Furnace For hardwood Charcoal Production

The airflow hoisting carbonization furnace is currently the…

Wood Powder Grinder Machine for Making Wood Flour

The wood powder machine is used for the…

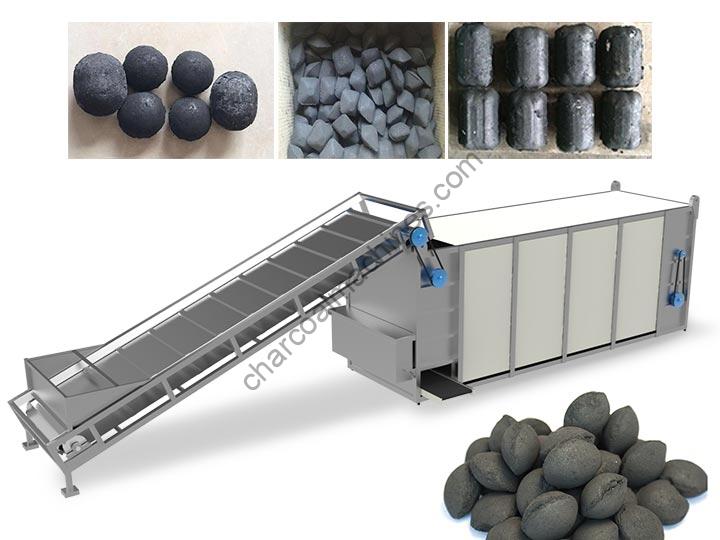

Mesh Belt Dryer for Drying Briquettes Continuously

The mesh belt dryer is a piece of…

Drum Wood Chipper for Wood Chips Mass Production

The wood chipper shredder machine mainly can be…

Honeycomb Coal Briquette Production Line | Briquettes Charcoal Processing Plant

The honeycomb coal briquette production line can turn…

Continuous Dryer for Drying Sawdust & Rice Husk

Industrial sawdust dryers and rice husk drying machines…

3 comments