How to make salt briquettes with a briquetter machine?

Salt briquettes are a convenient and efficient way to store and transport salt. They are also used in a variety of applications, including livestock feed, food processing, and industrial manufacturing.

While there are a number of ways to make salt briquettes, one common method is to use a briquetter machine. Shuliy’s briquetter machines are designed to compress powdered or granular materials into solid blocks.

Common types of salt briquettes

- Food-grade salt briquettes are made from food-grade salt, such as sea salt or kosher salt. They are typically used for cooking and baking.

- Industrial salt briquettes are made from a variety of salts, including rock salt, table salt, and brine. They are used in a variety of industrial applications, such as deicing, water softening, and chemical manufacturing.

- Pet salt blocks are made from a variety of salts, including rock salt, sea salt, and minerals. They are used as a source of salt for pets.

Salt briquette machine features

Salt briquettes can be made using a variety of methods, including manual compression, hydraulic compression, and thermal compression. The most common method is hydraulic compression, which is used by commercial salt briquette machines.

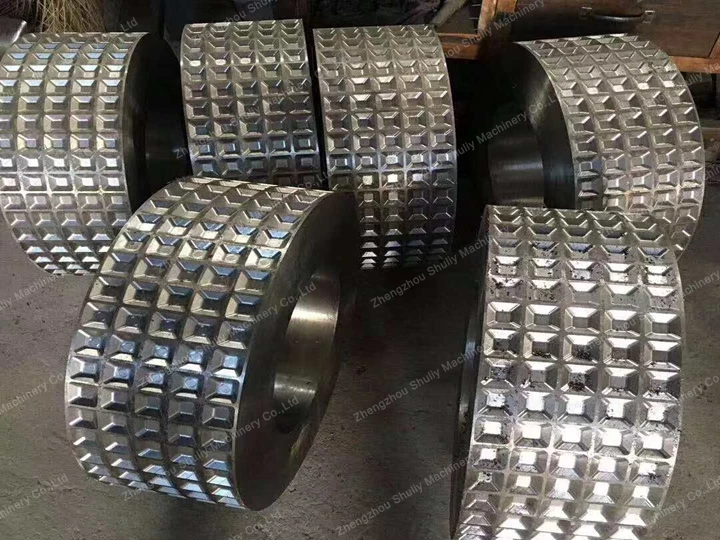

Hydraulic salt briquette machines use a hydraulic press to compress salt particles into solid salt briquettes. The Shuliy factory’s versatile briquetter machines can extrude all kinds of powdered or granular materials into balls, pillows, or oval shaped solids.

Salt briquetting process with the salt briquette machine

The process of making salt briquettes with a hydraulic briquetter machine can be divided into the following steps:

Preparation

The first step is to prepare the salt particles. This involves cleaning the salt to remove any impurities and then drying it to a desired moisture content. The moisture content of the salt will affect the strength of the briquettes.

Compression

The next step is to compress the salt particles. This is done by adding the salt particles to the salt briquette machine. The briquetting mold will compact salt into briquettes fast. And the briquetting mold can be customized. The pressure applied by the press machine will determine the density of the briquettes.

Packaging

After the salt compact cubes are finished, they can be packaged into bags with a certain weight for shipping or sale.

Benefits of using a salt briquette machine

- Efficiency: Briquette machines are highly efficient in converting loose salt into compact briquettes.

- Consistency: The machine ensures uniformity in size and shape, leading to consistent product quality.

- Cost-Effectiveness: By reducing the volume of salt through compaction, transportation and storage costs are minimized.

- Versatility: Briquette machines can be adapted for various materials and shapes, making them versatile for different industries.

Shuliy briquetter machine for sale

Using a briquetter machine to produce salt briquettes offers a practical and efficient solution for various industries. The process streamlines salt handling, reduces waste, and enhances the overall usability of salt in applications ranging from agriculture to chemical processing.

By choosing the right salt briquette machine, industries can contribute to sustainability and resource optimization while benefiting from the convenience and versatility of salt briquettes.

4 comments