Batch Charcoal Drying Machine with Good Performance

Charcoal Dryer | Briquettes Drying Machine

Batch Charcoal Drying Machine with Good Performance

Charcoal Dryer | Briquettes Drying Machine

Features at a Glance

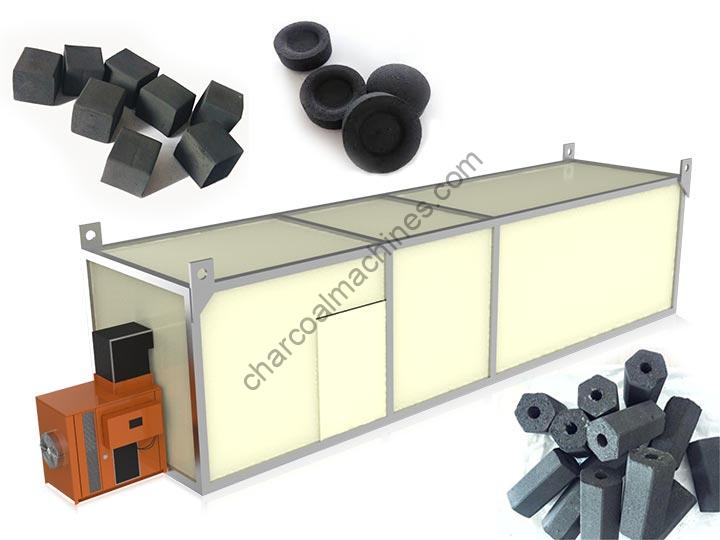

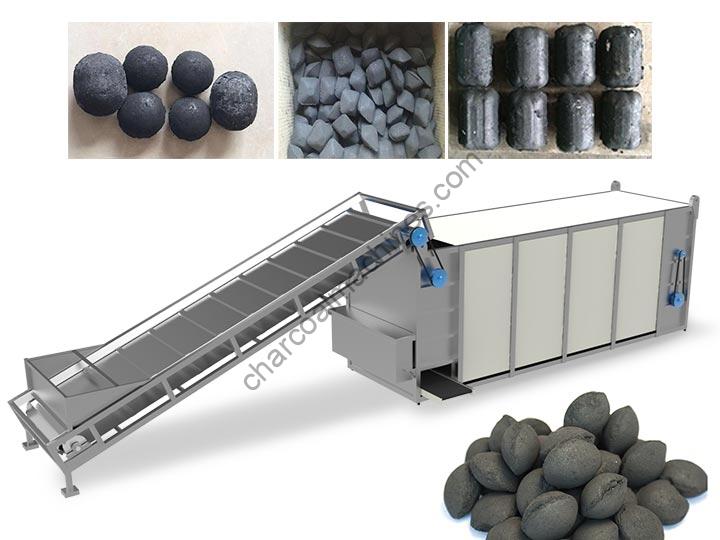

The charcoal dryer machine is mainly used to dry all kinds of charcoal briquettes, such as shisha charcoal, hookah charcoal, barbecue charcoal briquettes, etc. This industrial charcoal briquettes drying machine can adopt a variety of heating methods and is very convenient to use. In addition to drying charcoal, it can also be used to dry all kinds of fruits, vegetables, meat, etc.

Hookah charcoal dryer or bbq charcoal dryer is the ideal equipment for the quick drying of the shisha/hookah charcoal or barbecue charcoal briquettes, which is also named charcoal drying box or charcoal dryer room. The charcoal dryer machine is very suitable for commercial charcoal production lines to make charcoal in large quantities.

Besides, this charcoal drying machine is made of 304 stainless steel so that it can also be used to dry all kinds of the fruits and vegetables like date, pepper, carrot, bean, garlic, longan, agaric, hawthorn, mushroom, and so on.

And scented tea materials like chrysanthemum, lemon, rose, etc., and Chinese herbal medicine like ginseng can also be dried by this drying machine.

Introduction of charcoal briquettes drying machine

This box-type charcoal briquettes drying machine is mainly used to dry high moisture materials to a suitable moisture, achieving the maximum use-value of the material. The drying machine is widely used for drying charcoal or coal ball, shisha or hookah charcoal briquettes, coal briquettes, and so on.

This charcoal drying machine adopts a fully enclosed structure and the hot air circulates in the box, which can shorten the drying time of the materials and ensures product quality.

Generally, the dryer machine can reduce the materials’ moisture content from 40% to 8% for about 7-8 hours. And the machine has the features of easy installation, convenient demolition and relocation, and less floor space.

Charcoal dryer machine video

Working principle of the charcoal dryer machine

The outside part of the shisha charcoal briquettes dryer is specially designed with three layers. Its outer material is galvanized steel plate and the internal is polyurethane, which has good heat insulation and heat preservation effect.

The temperature control system can be designed with two types: one is the simple electricity cabinet with several buttons to control the power and the inner temperature of the dryer; the other one with the PLC control screen is very convenient for automatic control of the dryer.

There is a heat pump outside the drying box for making the hot air for drying. The inner structure of the dryer machine includes the fan, special drying carts, and drying trays.

The fan also has two types in this drying machine, one kind is for blowing the hot air into the room evenly, and the other is always set on the top of the room for extracting the moisture of the materials.

The drying cart is just a very simple frame with layers and wheels that can be moved easily in the drying room. The drying trays are always made of stainless steel so they are very suitable for drying the shisha charcoal or bbq charcoal briquettes because the stainless steel will not be stuck by the charcoal when drying.

Main advantages of the charcoal drying machine

- The charcoal dryer machine is very easy to install and maintenance with a simple structure. Its size can be customized according to customers’ requirements regarding the output.

- The temperature of the inner dryer room can be set and adjusted according to the material’s moisture content.

- The dryer room walls are made of a heat insulation board, and the inner heat insulation cotton material is very special, which can effectively reduce heat emissions.

- Except for drying the shisha/hookah charcoal and charcoal or coal ball, this drying machine can also be widely used for drying fruits and vegetables on large scale.

- Low investment, fast-drying speed, and high evaporation intensity.High working efficiency, large output, and good product quality.

Charcoal dryer machine technical parameters

| Model | Dimensions(mm) | Number of hot air fans(1 set/0.58KW) | Number of moisture extracting fans(1 set/0.12KW) | Induced draft fan(1 set/0.37KW) | Drying carts(group) | Amount of drying(each time/kg) |

| SL-2 | 4000*1600*2500 | 4 | 2 | 1 | 2 | 600 |

| SL-4 | 6000*1600*2500 | 4 | 2 | 1 | 4 | 1200 |

| SL-6 | 7200*2300*2500 | 6 | 2 | 1 | 6 | 1800 |

| SL-8 | 8800*2300*2500 | 6 | 2 | 1 | 8 | 2400 |

Charcoal drying machine in the charcoal briquettes processing plant

Hot Product

Charcoal Grinder Machine for Making Fine Charcoal Powder

The lump charcoal grinder machine also known as…

Charcoal Briquettes Packaging Machine for Packing Barbecue Charcoal Quantitatively

This quantitative charcoal briquettes packaging machine can be…

Wood Debarker Machine for Peeling Logs

Wood debarker machine, also known as the log…

Charcoal Coal Crusher | Charcoal Powder Grinder Machine

The charcoal crusher machine can mainly pulverize various…

Wood Sawdust Briquettes Production Line | Pini Kay Heat Logs Plant

The wood sawdust briquettes production line mainly extrudes…

Continuous Dryer for Drying Sawdust & Rice Husk

Industrial sawdust dryers and rice husk drying machines…

Hookah Charcoal Machine to Make Round & Cube Shisha Charcoal

Shuliy shisha charcoal press machine is designed according to…

Comprehensive Pallet Crusher for Shredding Wood Wastes

The comprehensive pallet crusher, namely the scrap wood…

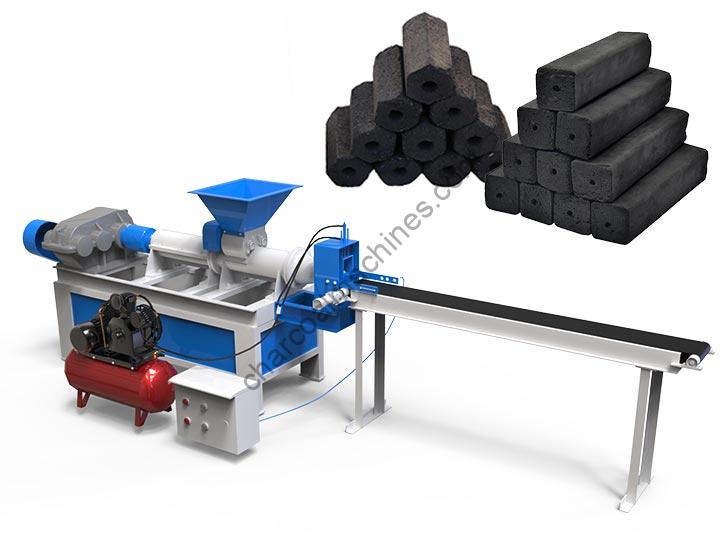

Charcoal Coal Briquettes Extruder Machine for Charcoal Plant

Charcoal briquette machine can extrude charcoal & coal…

5 comments