Compressed Wood Pallet Machine for Molded Pallet Production

Wood Pallet Machine | Hydraulic Pallet Press Machine

Compressed Wood Pallet Machine for Molded Pallet Production

Wood Pallet Machine | Hydraulic Pallet Press Machine

Features at a Glance

The compressed wood pallet press machine is a piece of industrial equipment specialized in processing various hot-pressed wooden pallets. This hydraulic wooden pallet press machine can make sawdust and rice husks of various sizes into wood pallets with high density and hardness by heating and pressing. And by changing different molds, the wood pallet machine can produce wood pallets of different specifications, sizes, and shapes.

What is the compressed wood pallet?

Compressed wood pallets are a new type of hot-pressed wooden pallets, but these wood pallets are not entirely made of wood but are made of wood chips, straw, sawdust, wood processing leftovers, rice husks, coconut shells, etc. Therefore, this kind of pressed wood pallet is very environmentally friendly and can promote the recycling and reuse of resources.

In addition, compressed wooden pallets also have the advantages of being lightweight, wear-resistant, non-toxic, tasteless, waterproof, and easy to recycle. At present, this environmentally friendly wooden pallet has been widely used in food, medicine, chemical, machinery, electronic appliances, auto parts, beer, and other industries, which can greatly improve work efficiency. In addition, with the huge development of the logistics industry, this wooden pallet is increasingly used in the transportation industry.

Features of compressed wood pallets

Molded industrial pallets are an important category of molded shavings products. They are mainly used to move and store goods in docks, freight yards, warehouses, workshops, shopping malls, and other places. It forms a mobile unit or handling unit with the goods, and it is combined with forklifts, trucks, and cranes. And other coordination effects.

The general specifications of industrial pallets are 400 mm~600 mm, 600mm~800mm, 800mm~1000mm, 1000mm~1200mm, and 1100mm~1100mm. The dynamic load capacity ranges from 250kg to 1500kg, and the pallet weight is 10kg to 20kg. The curved edges, trough beams, and ingenious and perfect reinforcement design of the pallet make the load factor up to 80 (dynamic load).

The shavings molded industrial pallet is a special-shaped, uniform-strength thin-shell member, with lightweight and high strength, and its load-bearing capacity to the self-weight ratio (loading capacity) is as high as 60-80 (dynamic load) and 200-300 (static load).

Structure of the industrial wood pallet machine

The main structure of a commercial wood pallet machine includes a frame, hydraulic device, mold, heat transfer cylinder (or boiler), etc. The mold of the machine can be replaced with different shapes, patterns, and sizes. The hydraulic device of the wood pallet machine is mainly to provide suitable pressure for wooden pallet forming.

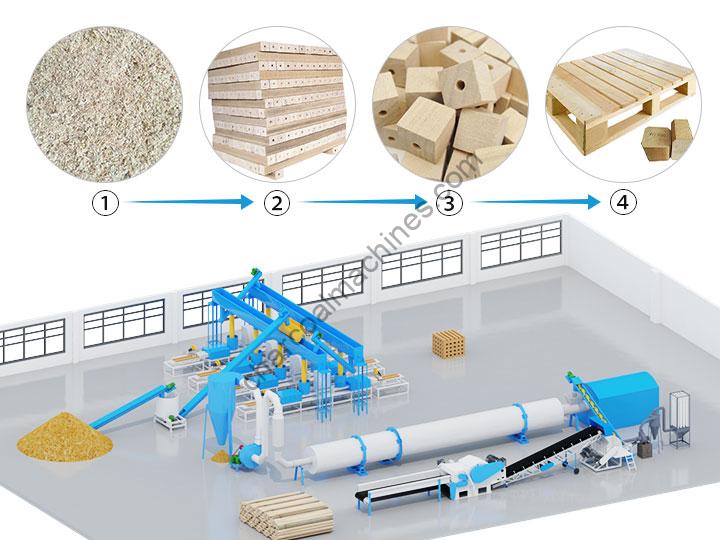

How to process the raw materials of the wood pallet press machine

- Raw materials crushing. Before using the wooden pallet machine, we must first prepare the raw materials. We need to use wood crushing equipment to crush branches, straws, etc., and process them into sawdust. In order to improve the efficiency of wood crushing and increase the output, we can use a wood chipper to process wood chips of larger sizes. Then use a hydraulic pallet press machine to crush the wood chips and turn them into higher-read wood chips.

- Sawdust drying. After the sawdust is processed, we need to dry it. Especially for wood chips with high moisture content, we need to use a sawdust dryer to dry them to reduce the moisture content to below 10%. If the user’s raw material moisture is not high, there is no need for drying.

- Glue and sawdust mixing. Before compressing the sawdust, we also need to mix the sawdust with glue. In order to improve the density and hardness of wooden pallets, we usually add an appropriate amount of liquid glue to the sawdust for mixing, such as environmentally friendly urea-formaldehyde resin glue.

How does the hydraulic pallets press machine work?

Before compressing the sawdust, we usually preheat the compressed wood pallet press machine. We can use the steam generated by the boiler as the heat source of the wooden pallet machine or use the heat-conducting oil furnace to conduct heat conduction heating into the mold of the pallet machine.

Then, we evenly pour the sawdust into the mold of the machine and flatten it. After pressing the down switch, the upper mold of the machine will be pressed down, and after about 7 minutes, a wooden pallet will be made.

After the wooden pallet is made, we need to manually remove it from the mold, or set up an automatic discharge device near the discharge port of the machine.

Features of the compressed wood pallet press machine

- The wooden pallet press machine is mainly used to press-molded pallets with wood chips, straws, waste chemical fibers, and other raw materials. It has an independent hydraulic system. After years of production practice in our factory, it has been proven to have good stability, high production efficiency, low energy consumption, convenient mold replacement, and can produce compression trays of various specifications.

- The hydraulic wood pallet machine has a reasonable structure design, adopts three-way synchronous positioning, precise balance of mold clamping, quick filling, and rapid pressurization, and can be fully pressurized in place within 35 seconds. After pressing the work button, the press can automatically complete the whole process of pressing down, pressurizing, pressure limiting, holding pressure, timing, pressure relief, demoulding, and rising to the position.

Hydraulic wooden pallet press machine video

Parameters of molded pallet press machine

| Model | SL-WP1000 |

| Power | 15kw |

| Pressure | 1000tons |

| Capacity | Produce one pallet need 4-5 minutes(can control by yourself ) |

| Dimension | 1.9*1.3*4m |

| Weight | 21000kg |

Hot Product

Wood Block Production Line for Making Compressed Wood Pallet blocks

Wood block production line can process high-quality compressed…

Continuous Charcoal Furnace for Biomass Charcoal Production

Continuous carbonization furnace is a new type of…

High-Efficiency Sawdust Briquette Machine for Sale

The industrial sawdust briquette machine is mainly used to…

Continuous Dryer for Drying Sawdust & Rice Husk

Industrial sawdust dryers and rice husk drying machines…

Wood Crusher for Making Sawdust from All Wood Wastes

Wood crushers are commonly used shredding equipment for…

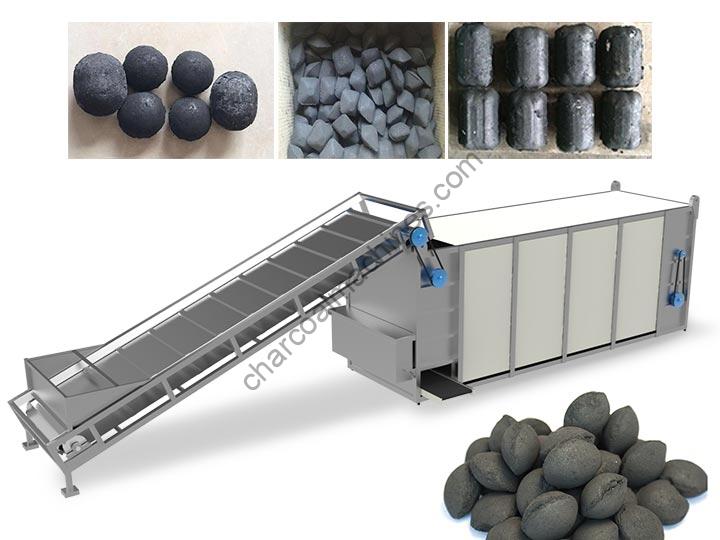

Shisha (Hookah) Charcoal Production Line | Briquette Packaging Dryer Plant

The automatic shisha(hookah) charcoal production line is the…

Mesh Belt Dryer for Drying Briquettes Continuously

The mesh belt dryer is a piece of…

Wood Pallet Block Machine for Making Pallet Blocks

Commercial wood pallet block making machines can extrude…

Charcoal Making Machine: The Ultimate Guide to High-ROI Biochar Production

The newest charcoal making machine is the ideal…

17 comments