Bakhoor Charcoal Machine Middle East: Why Demand Is Booming in UAE & Saudi Arabia?

The Middle East, especially the UAE and Saudi Arabia, has become one of the fastest-growing markets for bakhoor charcoal machines. With rising demand for premium incense, traditional fragrance rituals, and high-quality smokeless charcoal, local manufacturers and investors are actively looking for efficient charcoal production solutions.

Why Bakhoor Charcoal Demand Is Rising in the Middle East?

Bakhoor is deeply rooted in Middle Eastern culture and is widely used in homes, mosques, hotels, and luxury retail spaces. Unlike ordinary charcoal, bakhoor charcoal must be odorless, slow-burning, and produce minimal ash.

As consumption increases, many importers and local factories in the UAE and Saudi Arabia prefer to produce bakhoor charcoal locally, reducing import costs while maintaining stable product quality. This trend has directly driven the demand for advanced bakhoor charcoal machines.

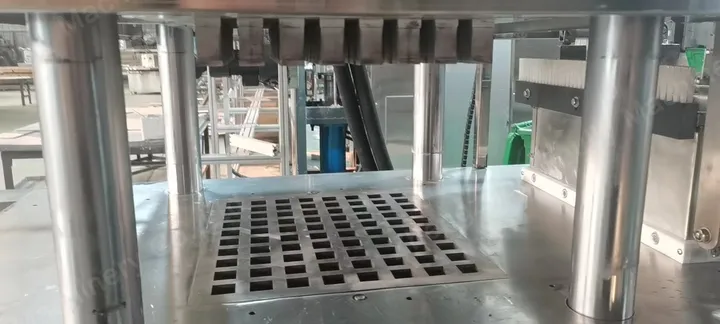

Square Bakhoor Charcoal Machine: The Most Popular Choice

Among different shapes, the square bakhoor charcoal machine is the most widely used in the Middle East market. Square bakhoor charcoal is easy to stack, pack, and burn evenly, making it ideal for both retail and commercial use.

Modern square bakhoor charcoal machines offer:

- Uniform briquette size and density

- High pressing strength for longer burning time

- Customizable mold sizes based on market demand

These advantages make square-shaped briquettes the preferred choice in UAE and Saudi Arabia.

Bakhoor Charcoal Production Process Explained

Understanding the bakhoor charcoal production process is essential for new investors. A standard process includes:

- Grinding raw charcoal into fine powder

- Mixing charcoal powder with natural binders

- Pressing the mixture using a bakhoor charcoal machine

- Drying the briquettes to achieve low moisture content

- Packaging for wholesale or retail distribution

A well-designed production line ensures stable quality and high output efficiency.

Bakhoor Charcoal Machine Price: What Affects the Cost?

The bakhoor charcoal machine price varies depending on capacity, automation level, and mold configuration. Small machines for startups are budget-friendly, while industrial models with higher output cost more.

For Middle East buyers, investing in a reliable machine means long-term savings through lower labor costs, consistent quality, and strong market competitiveness.

Welcome to Contact Shuliy Machinery for the Bakhoor Charcoal Machines

With strong cultural demand and growing local production, the Middle East remains a promising market for bakhoor charcoal manufacturing. Choosing the right bakhoor charcoal machine is the key to success in the UAE and Saudi Arabia’s competitive incense industry.

Shuliy Factory, with over a decade of experience as a supplier specializing in the production and manufacturing of charcoal processing equipment, offers cost-effective charcoal processing solutions to every client who consults or visits us. We welcome your inquiries.

Comments are closed.