Drum Wood Chipper for Wood Chips Mass Production

Large wood chipper | Wood chips machine

Drum Wood Chipper for Wood Chips Mass Production

Large wood chipper | Wood chips machine

Features at a Glance

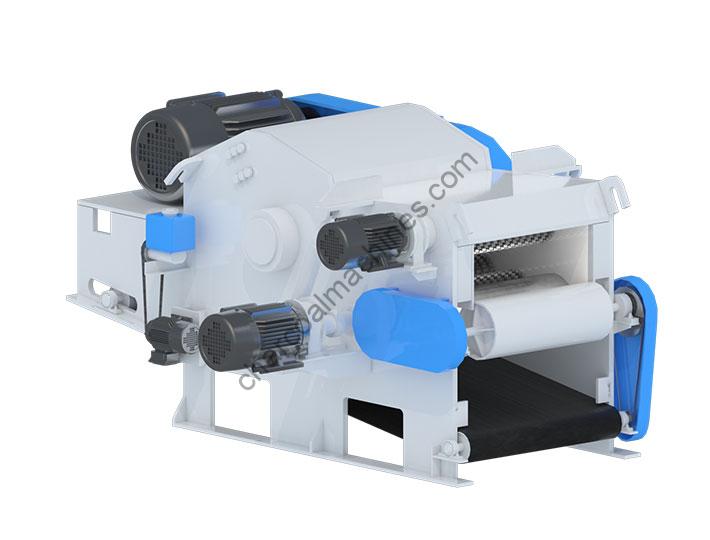

The drum wood chipper machine is commercial wood processing equipment for making wood chips on a large scale. Drum chipper is a kind of practical equipment for processing all kinds of wood. It is widely used in the pre-processing stage for manufacturers of particleboard factories, medium, and high-density board factories, bio-power plants, and wood chip factories.

Logs and small-diameter wood can be cut into high-quality industrial wood chips with uniform length, flat cut, and uniform thickness by this large wood chipper, and it can also cut branches, slabs, and plates.

What is the drum wood chipper?

The wood chipper shredder machine mainly can be divided into the drum wood chipper and the disc type wood chipper. Compared with the disc wood chipper machine, this drum wood chipper is larger in size and working capacity.

The main cutting system in the disc wood chipper is the cutter plate which can cut the wood or logs with small sizes. However, the drum wood chipping machine has a big cutter roller which is efficient and durable for cutting the wood chips from all kinds of wood.

Drum wood chipper video

Structure of the commercial drum wood chipper

This wood chips making machine consists of the body, the cutter roller, the upper and lower feed rolls, the conveyor belt, and the hydraulic system.

The body of the drum wood chipper is welded with high-strength steel plates and is the basis for the support of the entire machine.

Its cutting device is a rotating drum wheel, two or three or four flying knives are mounted on the cutter roller, and the flying knives are fixed on the cutter roller by a pressure block.

During the wood chipping process, the flying knives will rotate continuously and cut the logs into wood chips quickly.

This drum chipper machine’s hydraulic system is supplied by an oil pump to the cylinder, and its cover can be activated to facilitate the replacement of the blade.

The upper feeding roller assembly can be lifted during maintenance, which is convenient for adjusting the gap between the flying knife and the bottom knife and the disassembly and assembly of the comb plate.

How does a drum chipper shredder work?

Drum wood chipper working video

The wood can be fed manually into the drum wood chipper’s feed port or to the machine’s feed port by means of a flat plate conveyor.

The drum chippers have two pairs of rollers at the feed port, which, when turned, press the wood and transport it to the cutter at a constant rate.

When the wood comes into contact with the cutting blade, it is cut with the high-speed rotation of the cutting knife roller, and the cut wood is sent out by the high-speed steam flow generated by the wind blade on the cutting roller in the cutting room.

There is a plurality of squares through holes on the outer edge of the drum cutter, which can smoothly discharge the wood chips.

The feeding mechanism is composed of a feeding interface, an upper and lower feeding roller, and a feeding gap adjusting mechanism, and the wood entering from the feeding interface is fed up and down.

Pressed and fed to the cutting mechanism at a certain speed to control the size of the cutting chips. When processing thick wood, it is adjusted by the feed gap mechanism. After the wood chips have been screened, the larger ones have to be smashed between the blades and the baffles again.

Applications of the wood chipper machine

Drum wood chippers are often used in the early stage of preparation for textile, paper, pulp, wood-based panels, etc. The drum wood chippers are mainly used for cutting branches, bamboo, slats, small diameter wood, and wood sheets with diameters or thicknesses below 120 mm.

However, if the diameter is too thick (350mm or more), too thin (30mm or less), or too short (250mm or less) or extremely thin (5mm or less) and irregular raw materials (undecomposed tree stumps, branches, etc.) do not have the function of uniform cutting.

Or just raw materials cut off on the original basis, and the slice of bamboo with a wall thickness of less than 5 mm is insufficient. It mainly cuts the residue from forest harvesting and wood processing into wood chips of uniform size.

Main advantages of the industrial drum wood chippers

- The alloy cutter of the chipper is very wear-resistant and has advanced manufacturing technology. Its unique comminution system design greatly increases the service life of the equipment. The crushing chamber of the wood chipper adopts a multi-stage crushing structure and a fine crushing principle device, which is characterized by high working impact force, high production efficiency, and strong fine crushing ability.

- The logs chipper is less in its spare parts, and has a low operating cost, reasonable structure, advanced crushing principle and technology, and simple operation; all parts of the wood crusher are wear-resistant, reducing maintenance costs to a limit, and the general service life can be increased by 30% the above.

- This drum wood chipper can be different models with different working capacities. And it can be designed with the fixed type and movable type. The movable type of wood chipper has wheels so that it can be widely used in many production situations.

Reasons for the large vibration of the drum wood chipper

- The wood chipper is operated without oil in the hydraulic system;

- The oil pressure in the cylinder is not enough;

- The nitrogen pressure of the accumulator is not enough or the pressure is too high;

- The damage of the shut-off valve causes the oil pressure to decrease;

- The sharpening or weight of the two flying knives are inconsistent;

- The direction of the one-way throttle valve is reversed, the oil cannot enter the cylinder quickly, and the oil is too fast when returning oil which will cause a vibration.

Hot Product

Small Feed Pellet Machine for Making Animal Feeds

The small feed pellet machine is the home…

Wood Powder Grinder Machine for Making Wood Flour

The wood powder machine is used for the…

Briquette Cutters for making briquette charcoal as required

The charcoal briquettes cutting machine is used to…

Compressed Wood Pallet Machine for Molded Pallet Production

The compressed wood pallet machine is a piece…

Flue Gas Purification Equipment

Flue gas purification In the past, due to…

Comprehensive Pallet Crusher for Shredding Wood Wastes

The comprehensive pallet crusher, namely the scrap wood…

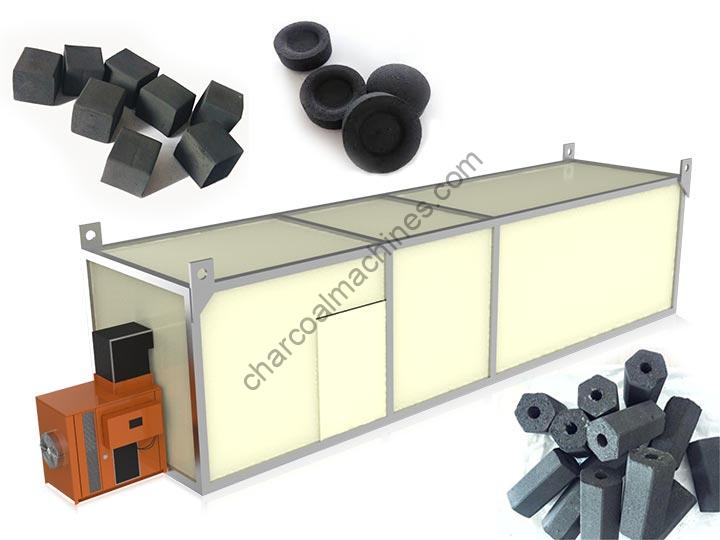

Batch Charcoal Drying Machine with Good Performance

The charcoal dryer machine is mainly used to…

Raymond Mill for Grinding Fine Charcoal Powder

Raymond mill is mainly used as a piece…

Wood Debarker Machine for Peeling Logs

Wood debarker machine, also known as the log…

No Comments.