Honeycomb Coal Briquette Press Machine

Coal Briquettes Press Machine | Honeycomb Charcoal Briquette Machine

Honeycomb Coal Briquette Press Machine

Coal Briquettes Press Machine | Honeycomb Charcoal Briquette Machine

Features at a Glance

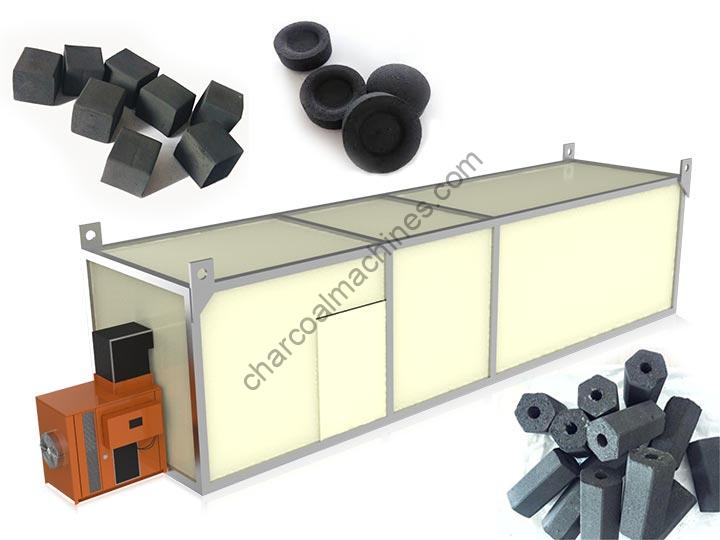

The honeycomb coal briquette press machine produced by Shuliy Machinery is one kind of charcoal briquette machine for making charcoal briquettes or coal briquettes. The raw materials for pressing in this charcoal machine are mainly charcoal powder and coal powder.

Before briquetting, we may use the charcoal grinder and the binder mixer to process the charcoal powder first. This process can make sure the final charcoal or coal briquettes with high density and smooth appearance for selling at good prices.

The main structure of the honeycomb coal press machine

The structure of the honeycomb coal machine is very compact and the degree of automation is high. The honeycomb coal machine is mainly composed of four sliding rods, sliding beams, punches, punch seats, punches, rotating pressure plates, movable die bottoms, and springs.

The conveyor belt of the machine’s discharge port can be rotated randomly to convey the formed coal briquettes. The adjustable screws on the conveyor frame of the Honeycomb coal press machine can be used to adjust the tightness of the conveyor belt.

The structure of the honeycomb coal machine is mainly divided into five parts: the body frame, the transmission system, the feeding device, the stamping system, and the conveying device. When the machine is started, the motor of the coal press machine is driven to drive the toothed pulley to rotate and pass to the drive shaft through two gears, and then drive the dial through a pair of bevel gears and the rotating shaft.

The sliding beam is driven by the rotation of the two gears through the pull rod. When the punch goes down, the movable plate moves up, the spring is tightened, and the pulverized coal is pressed into shape. The density and hardness of coal briquettes are determined by the pressure of the spring pressing the movable platen.

Coal briquettes press machine video

Honeycomb coal machine working principle

The honeycomb charcoal briquette machine can press the pulverized charcoal powder or coal powder into briquettes with a certain shape. It is mainly composed of five parts: main body, transmission part, feeding part, molding part, and transport part.

Especially the molding part is the most interesting part for it can be changed with different molds for making different shapes of coal briquettes. Adding the powdery material to the machine for stamping, forming, and demoulding, and then we can get the final solid charcoal or coal briquettes.

Advantages of the honeycomb charcoal briquette machine

The charcoal or coal briquettes made by this honeycomb coal machine marked with a number of holes inside the cylinder makes it seems like a honeycomb because it can increase the surface area of the coal briquettes so that they are easy to be ignited and can burn enough.

The coal briquettes can be 4, 9, 12, 14, 16, 18, 19, 20 holes with round, honeycomb, cylinder, and flower shapes, and which have high density and good appearance, easy for moving and storage.

In the production process, the length and diameter of the coal briquettes can be customized according to the requirements of the customers, and it can be used as a multi-purpose machine, which is convenient and practical.

Applications of honeycomb charcoal press machine

The honeycomb coal briquette press machine has been improved several times and was once mainly used for household fire, heating, and honeycomb-shaped cylindrical briquettes made of anthracite. In the past, people processed pulverized coal into spheres slightly larger than table tennis.

Now, we make the coal briquettes by the charcoal making machine with holes and different shapes which can increase the surface area of coal, enable coal to burn fully, and reduce resource waste. Most of these charcoal and coal briquettes are used for barbecue, cooking, and home or industry heating.

Features of honeycomb coal machine

The honeycomb coal machine has a simple structure and is divided into five parts: a body, a rotation, a feeding, a stamping, and a conveying. The parts work together and the operation is coordinated and stable.

- The body part: consists of a platen and a machine base, which are opened into the skeleton of the machine.

- Transmission part: It consists of a motor, pulley, gear, driveshaft, and other components. The motor rotates the gear shaft through the pulley and transmits it to the transmission shaft through two gears. The pair of bevel gears and the rotating shaft drive the dial, and the dial is turned to move to the four-hole disc.

- Feeding part: It consists of a rotating shaft, a hopper, and a stirrer. It is driven by an axial gear to stir the coal and mix it into the mold.

- The stamping part mainly consists of four sliding rods, a sliding beam, a punching rod, a punching seat, a punching head, a movable pressing plate, movable mold bottom, and a spring. When the honeycomb coal press machine rotates, the two gears rotate through the pull rod to drive the sliding beam. When the punch goes down, the punch is forced to move down, the movable plate moves up and the spring is tightened, the coal is pressed and the coal is punched, and the formed coal is loose, by the spring. Press the active plate to determine the compression of the coal.

- The conveying part is composed of a conveyor frame, a pulley, a bracket, and a conveyor belt. The conveyor belt is randomly rotated to send the shaped coal out of the body, and the adjustable screw on the conveyor can adjust the tightness of the conveyor belt.

Honeycomb coal briquette press machine video

Honeycomb coal briquette machine parameters

| model | XFM125 | XFM83 | FM220 | FMJ102 | FMJ-120 |

| Forming height(mm) | 70-100 | 70-90 | 75-90 | 70-80 | 70-80 |

| Number of punches(Times/minute) | 48 | 48 | 35 | 45 | 48 |

| Number of buckets (piece) | 1 | 1 | 1 | 1 | 1 |

| Power (kW) | 7.5 | 7.5 | 11 | 4.5 | 7.5 |

| Machine weight(kg) | 1600 | 1800 | 3800 | 1100 | 1400 |

| Molded coal specification(mm) | φ100×75 φ125×75 | φ150×90 φ140×90 | φ220×90 φ200×90 | φ100×75 φ120×75 | φ120×75 φ100×75 |

The cooperative customers of compressed coal briquette machine

This kind of coal briquettes forming machine is currently popular in many African countries and Southeast Asian countries. The countries with the most deals with our Shuliy factory in the past three years are Uganda, South Africa, Ghana, Congo, Ethiopia, Nigeria, Israel, Iraq, Philippines, Vietnam, Cambodia, South Korea, the United States, Chile, and Argentina. If your charcoal factory also wants to process different shapes of coal briquettes, welcome to inquire with us. We will provide you with all the relevant information and quotations of the machine.

Hot Product

Small Feed Pellet Machine for Making Animal Feeds

The small feed pellet machine is the home…

Batch Charcoal Drying Machine with Good Performance

The charcoal dryer machine is mainly used to…

Round & Pillow Barbecue Charcoal Ball Press Machine

Barbecue charcoal press machine can make compressed charcoal…

Wood Shaving Machine for Animal Bedding

The wood shaving machine can process logs and…

Charcoal Briquettes Packaging Machine for Packing Barbecue Charcoal Quantitatively

This quantitative charcoal briquettes packaging machine can be…

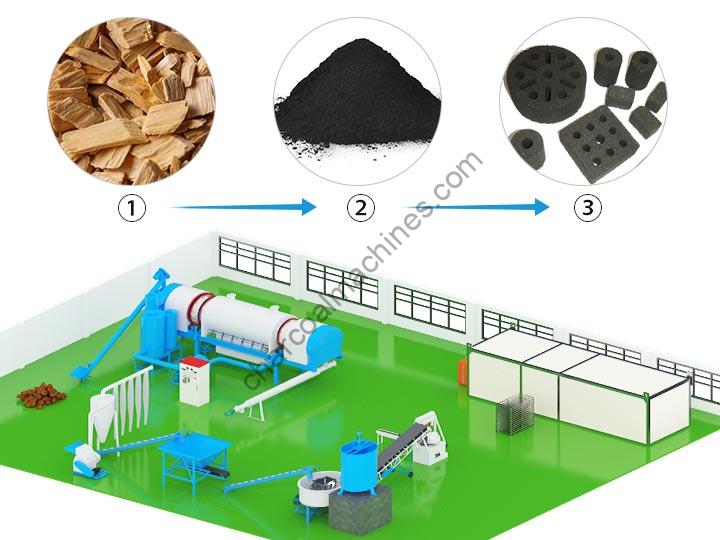

Barbecue Charcoal Production Line | BBQ Briquettes Processing Plant

The barbecue charcoal production line mainly processes various…

High-Efficiency Sawdust Briquette Machine for Sale

The industrial sawdust briquette machine is mainly used to…

Compressed Wooden Pallet Production Line

The compressed wooden pallet production line is a…

Industrial Wood Pellet Machine for Sale

Wood pellet machine refers to the compression of…

No Comments.