Charcoal Making Machine: The Ultimate Guide to High-ROI Biochar Production

Newest charcoal making machine | Integrated carbonization machine

Charcoal Making Machine: The Ultimate Guide to High-ROI Biochar Production

Newest charcoal making machine | Integrated carbonization machine

Features at a Glance

Are you looking for an efficient way to turn biomass waste into a high-value product? The Shuliy charcoal making machine is an advanced carbonization solution designed to convert various organic materials into premium biochar. This powerful pyrolysis plant is engineered for businesses aiming to capitalize on the circular economy, transforming waste streams like wood, coconut shells, rice husks, and even sludge into profitable resources. Whether you’re a large-scale agricultural enterprise or a waste management facility, this machine offers a sustainable and lucrative investment opportunity.

Our continuous charcoal making machine is built for industrial-scale production, with a processing capacity ranging from 800kg to 3 tons per hour, depending on the model. This makes it the ideal choice for medium to large charcoal processing plants and investors ready to lead in the sustainable energy market. Let’s explore how this technology can revolutionize your operations.

What Raw Materials Can a Charcoal Making Machine Process?

One of the greatest advantages of our charcoal making machine is its versatility. It can process a vast array of organic and inorganic wastes, making it a comprehensive solution for waste-to-energy projects. By carbonizing these materials, you not only produce high-quality charcoal but also significantly reduce waste volume, minimize environmental pollution, and create a valuable energy source.

Common Biomass & Agricultural Waste:

- Wood & Forestry Residues: Sawdust, wood chips, branches, tree roots, bark, bamboo.

- Agricultural Husks & Shells: Coconut shells, rice husks, palm kernel shells, walnut shells, peanut shells, olive pits.

- Crop Stalks & Other Biomass: Straw, hemp stalks, coffee grounds, sugarcane bagasse, fruit bran.

Municipal & Industrial Waste:

- Sludge: Municipal sludge, river sludge, industrial sludge, printing and dyeing sludge.

- Municipal Solid Waste (MSW): Sorted domestic garbage, paper mill waste.

- Other Wastes: Animal manure, chemical wastes like activated coke.

How Does a Charcoal Making Machine Work? A Step-by-Step Process

The charcoal production process is a highly efficient, continuous operation based on the principle of pyrolysis. Pyrolysis is the thermal decomposition of materials at elevated temperatures in an oxygen-deprived environment. Here’s how our machine turns waste into charcoal:

- Pre-treatment of Raw Materials: For optimal results, raw materials should have a moisture content below 15% and a size smaller than 20mm. Materials that don’t meet these criteria are first processed by a crusher and then a dryer.

- Feeding and Carbonization: The prepared material is fed into the main carbonization furnace via an automated conveyor. Inside the rotating, dual-layer drum, the material undergoes high-temperature pyrolysis. The process takes approximately 15-25 minutes at temperatures between 380°C and 450°C.

- Syngas Recycling & Self-Sufficient Heating: As the material carbonizes, it releases combustible gas (syngas). This gas is collected, purified through a cyclone dust removal system, and then redirected to the combustion chamber to heat the furnace. After the initial preheating phase, the machine becomes self-sufficient, significantly saving on fuel costs.

- Charcoal Discharge and Cooling: The finished charcoal is discharged through a water-cooled conveyor system. This process rapidly cools the charcoal, preventing re-combustion and making it safe for immediate collection and packaging.

- Flue Gas Purification: Any excess flue gas is treated through a multi-stage purification system (e.g., water spraying, adsorption) to ensure emissions meet strict environmental standards before being released.

https://youtu.be/xVcNOnv-SHMWatch the charcoal making machine working process

Key Components of Shuliy’s Charcoal Making Machine

Our machine is an integrated system where each component is optimized for maximum efficiency, durability, and safety. Here are the core parts of our charcoal production line:

Carbonization Main Body (Reactor)

The heart of the machine. It features a double-layer drum made from high-temperature-resistant stainless steel. The robust design ensures even heating and long service life, with an inner cylinder thickness of 10mm for superior durability.

Drying System

An optional but highly recommended component. The dryer pretreats raw materials to reduce moisture, which dramatically improves carbonization efficiency and the quality of the final charcoal.

PLC Electric Control Cabinet

For safe, smart, and centralized operation. The PLC cabinet allows you to monitor and control all operational parameters in real-time, including temperature, pressure, and running speed, ensuring stable and secure production.

Syngas Purification & Cooling System

This system is crucial for eco-friendly operation. It cleans the syngas before it’s reused as fuel and also allows for the collection of valuable by-products like wood vinegar and tar, creating additional revenue streams.

Why Invest in a Charcoal Making Machine? The Business Case

Investing in a Shuliy charcoal making machine is more than just purchasing equipment; it’s a strategic business decision with a high potential for return on investment (ROI). Here’s why:

- Turn Waste into Profit: Convert low-cost or zero-cost biomass and industrial waste into high-demand charcoal, a product with a stable and growing market.

- Multiple Revenue Streams: Besides charcoal, you can sell valuable by-products like wood vinegar (for organic pesticides) and tar (for industrial applications).

- Eco-Friendly & Sustainable: This technology promotes a circular economy. By producing biochar, you participate in carbon sequestration, helping to reduce greenhouse gases. This can make your business eligible for carbon credits and government incentives.

- Energy Self-Sufficiency: The syngas recycling system drastically reduces your operational fuel costs, making the production process more profitable and resilient to energy price fluctuations.

Wide Applications of the Final Charcoal (Biochar)

The charcoal produced by our machine is of high quality, with a fixed carbon content that can exceed 80-90%. This makes it suitable for a wide range of profitable applications:

- As Fuel: An excellent, eco-friendly fuel for BBQ, shisha/hookah, and industrial heating in cement plants, boiler factories, etc.

- In Agriculture (as Biochar): A powerful soil amendment that improves soil structure, increases water retention, enhances nutrient absorption, and boosts crop yields.

- In Industry: Can be used as a reducing agent in metallurgy, or further processed to produce activated carbon for water and air purification.

- Carbon Sequestration: Biochar provides a stable, long-term method of storing carbon in the soil, actively combating climate change.

Technical Parameters of Shuliy Charcoal Making Machine

We offer several models to meet different production scales and investment budgets. Below are the specifications for our most popular charcoal making machines.

| Item | Details | |||

| Model | SL-JH-0812 | SL-JH-1015 | SL-JH-1218 | SL-JH-1320 |

| Hourly Feeding Capacity | 500kg | 0.8-1 Tons | 1.5-2Tons | 2.5-3Tons |

| Working Method | Continuous Carbonizing | |||

| Reactor Size | Φ800mm | Φ1000mm | Φ1300mm | Φ1700mm |

| Heating Materials | Charcoal, wood, diesel, natural gas, LPG, biomass pellets, etc. | |||

| Total Power | 40kw/h | 55kw/h | 60kw/h | 72kw/h |

| Floor Area (L*W*H) | 30m*15m*7m | 35*15*7m | 45*15*10m | 50*15*10m |

| Operating Pressure | Constant Pressure | |||

| Cooling Method | Recycling Water Cooling | |||

| Life Span | 5-8 Years |

charcoal making machine parameters

Why Choose Shuliy Machinery?

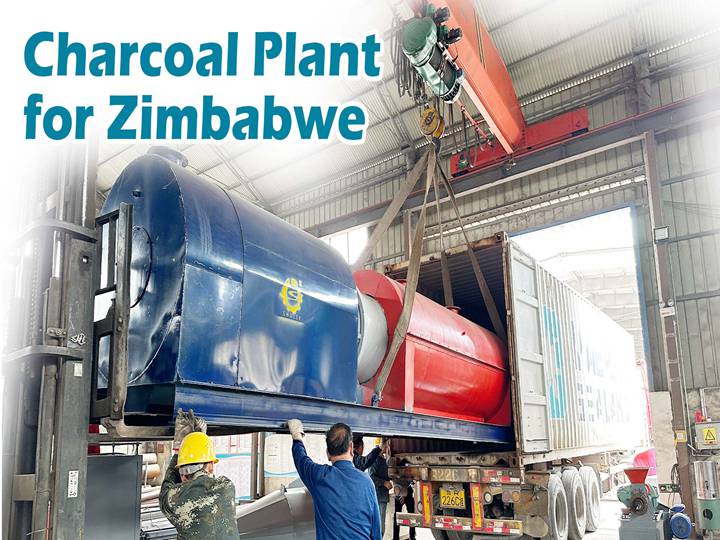

- Proven Expertise: With years of experience in manufacturing and exporting, we have successfully installed charcoal production plants in numerous countries, including Malaysia, Brazil, and across Europe.

- Quality and Durability: We use high-grade, heat-resistant materials and robust engineering to build machines that last, ensuring you get the best value for your investment.

- Customized Solutions: Our engineering team will work with you to design a charcoal production line tailored to your specific raw materials, site conditions, and business goals.

- Comprehensive Service: We provide full support, from initial consultation and solution design to overseas installation, operator training, and lifetime after-sales service.

See our successful charcoal plant installation in Malaysia

Frequently Asked Questions (FAQ) about the Charcoal Making Machine

1. What is the price of the charcoal making machine?

The price varies depending on the model, capacity, and configuration (e.g., inclusion of a dryer, crusher). To get an accurate quote tailored to your needs, please contact our sales team with your raw material type, desired capacity, and final charcoal usage. We will provide a detailed proposal and price list.

2. What is the difference between this machine and a traditional kiln?

Our continuous charcoal making machine is far more efficient, eco-friendly, and controllable than a traditional kiln. It offers continuous production (vs. batch processing), recycles combustible gas to save fuel, has a complete smoke purification system to prevent pollution, and produces higher quality charcoal with a consistent yield.

3. How long is the service life of the machine?

With proper maintenance, the main components of the Shuliy charcoal making machine have a service life of 5-8 years. We use high-quality, durable materials to ensure longevity and provide comprehensive after-sales support for spare parts.

4. Can I see the machine in operation?

Absolutely. We have numerous videos of our machines in operation at client sites around the world. We can also arrange a visit to our factory or a nearby client’s plant, depending on your location and availability. Please contact us to coordinate.

Get Your Customized Charcoal Production Solution Today!

Ready to transform waste into wealth and build a sustainable business? The Shuliy charcoal making machine is your key to unlocking the potential of biomass. Contact us today for a free consultation and a personalized quote. Our experts are ready to help you launch your profitable charcoal production project.

Charcoal Making Machine

This newest charcoal making machine is carbonization equipment designed and manufactured by the Shuliy factory for processing various types of biomass charcoal. This integrated carbonization machine can carbonize biomass wastes, crop wastes, municipal wastes, sludge, animal manure, etc. This charcoal making machine is also efficient equipment for processing coconut shell charcoal, wood charcoal, sawdust charcoal, bamboo charcoal, palm shell charcoal, etc.

Product Brand: Shuliy Group

Product Currency: USD

Product Price: 27000

Price Valid Until: 2028-07-31

Product In-Stock: InStock

5

Pros

- I am very satisfied with this equipment!

- Great! The quality of the charcoal produced has been greatly improved.

- Shuliy helped me with installation and technical guidance, and will cooperate again.

- This machine produces very good charcoal.

- The preferred equipment for charcoal producers.

Hot Product

Drum Wood Chipper for Wood Chips Mass Production

The wood chipper shredder machine mainly can be…

Horizontal Charcoal Furnace For Biochar Carbonization

The horizontal charcoal furnace is the high efficient…

Flue Gas Purification Equipment

Flue gas purification In the past, due to…

Wood Pallet Block Machine for Making Pallet Blocks

Commercial wood pallet block making machines can extrude…

Small Feed Pellet Machine for Making Animal Feeds

The small feed pellet machine is the home…

Compressed Wooden Pallet Production Line

The compressed wooden pallet production line is a…

Continuous Dryer for Drying Sawdust & Rice Husk

Industrial sawdust dryers and rice husk drying machines…

Wood Hammer Mill for Recycling Wood Scraps

Wood hammer crusher mill can crush wood chips,…

High-Efficiency Sawdust Briquette Machine for Sale

The industrial sawdust briquette machine is mainly used to…

No Comments.