Continuous Dryer for Drying Sawdust & Rice Husk

Sawdust Dryer | Rice Husk Drying Machine

Continuous Dryer for Drying Sawdust & Rice Husk

Sawdust Dryer | Rice Husk Drying Machine

Features at a Glance

Industrial sawdust dryers and rice husk drying machines mainly include airflow dryers and rotary drum dryers. The sawdust drying machine can dry sawdust, rice husks, wood chips, straw scraps, etc. with a moisture content of less than 60% to make the moisture content less than 10%. The dried sawdust and rice husk can be used to process sawdust briquettes, pini-kay, wood pellets, wood boards, paper, furniture, etc.

The heat source of the sawdust and rice husk drying machine mainly uses the heat of burning biomass raw materials, and the heat can be recycled during the drying process, which is very energy-saving. Due to their high drying efficiency, these commercial sawdust dryer machines are often used in various charcoal production lines and paper mills.

Classifications of sawdust & rice husk drying machine

At present, the drying equipment used for drying sawdust and rice husk is mainly an air-flow sawdust dryer and drum sawdust dryer. The appearance, structure, working principle, processing capacity, and application scenarios of these two automatic dryer machines are very different.

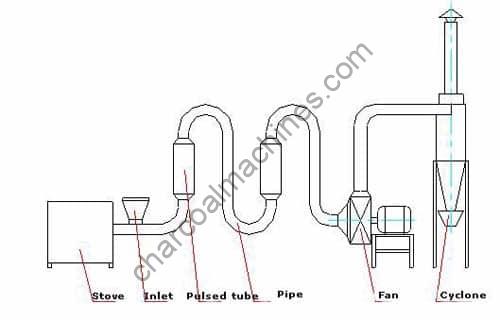

Airflow rice husk dryer machine

The airflow rice husk dryer machine is also called a pipe type dryer, which is a piece of ideal drying equipment with a small investment and fast profits. This airflow rice husk dryer machine is the continuous and rapid drying equipment that is usually used in charcoal production lines.

The loose granular materials will suspend in hot air, and go through instantaneous moisture removal in the drying process. This airflow drying machine is suitable to dry granular materials like sawdust and rice husk. After drying, the raw materials’ moisture content will be less than 10%.

Airflow sawdust dryer machine’s working process

Wood, branches, logs, bamboo, straw, sugarcane bagasse, and other biomass materials should be crushed into sawdust by the wood crusher machine before drying. The requirement of the raw materials for drying in the airflow sawdust dryer is less than 5mm in diameter.

In front of the airflow dryer, there will be an ignition stove for providing hot air like the rotary dryer machine. After the sawdust or rice husk is added to the dryer, it will flip in the pipes with the fore of the fan. The material is evenly dispersed in the drying machine and in full contact with the hot air to accelerate the drying speed.

In the drying process, under the action of hot gas, the material is discharged from the dust collector at the end of the dryer after drying. The high-temperature hot air in the airflow drying machine in the drying tube with high-speed, the residence time is very limited, therefore, generally only applicable to the material surface moisture evaporation constant speed drying process.

The working principle of the airflow sawdust drying machine is to send granular wet materials into the hot air flow and get dry granular products. The airflow rice husk dryer has a good effect on reducing the environmental pollution.

Applications of the airflow dryer for sawdust drying

Airflow dryer machine is widely used in metallurgy, building materials, feed, mining, food, medicine, chemical, pharmaceutical, coal washing, fertilizer making, light industry, and charcoal production industries.

The output of the rice husk drying machine is different according to the moisture of the raw materials, which ranges from 200kg/h to 600kg/h. The smaller the moisture content of the material, the larger the output of the dryer.

In the charcoal production line, the air dryer machine is mainly used behind the crusher after the material is crushed, the granular wet material is quickly dried into the required granular dry products. After that, the materials are transported by screw feeding machine to sawdust briquette machine and carbonization furnace, to further charcoal production.

Features of the airflow rice husk drying machine

- Drying raw materials: rice husk, sawdust, shavings, branches, wood chips, and other granular raw materials after grinding (diameter less than 3mm, length less than 5mm).

- The production efficiency: hot air is 180 ℃, the relative humidity of 35% of sawdust or rice husk dry to the relative humidity is 10%, the hot air temperature is not lower than 180 ℃, the discharging mouth temperature of 40-50 ℃.

- Fuel options: wood chips, branches, coal, steam, or electric heating.

- High drying intensity and low equipment investment. Airflow drying machine of large processing, water evaporation capacity, with small size and less investment, is incomparable to other drying machines.

- The high degree of automation and good product quality. During the drying process, the material is completely carried out in the pipeline, and the drying time is very short (only 2-10 seconds). During this period, the heat is mainly used for water evaporation, and the temperature of the material itself does not rise much, so the temperature has little influence on the product. Therefore, the product does not contact with the outside world, can be small pollution and good quality.

- Complete equipment supply and the heat source are optional. Users can configure corresponding equipment according to material conditions and process requirements.

- As for the selection of heating mode, due to the great adaptability of airflow drying machine, users can choose electric heating, steam heating, heat conduction oil heating, coal burning hot air furnace, gas hot air furnace, steam + electric heating, and other combined forms according to the conditions of the location of the equipment.

Technical parameters of airflow sawdust dryer machine

| Model | Motor power | Output | Weight | Feed

diameter | Dimension |

| 350 | 7.5kw | 180-300kg/h | 1.5T | ≤5mm | 15.0*2.6*3.8m |

| 400 | 15kw | 700-900kg/h | 2.5T | ≤5mm | 16.0*2.6*4.0m |

Airflow rice husk drying machine video

Features of the airflow drying machine

- Drying raw materials: rice husk, sawdust, shavings, branches, wood chips, and other granular raw materials after grinding (diameter less than 3mm, length less than 5mm).

- The production efficiency: hot air is 180 ℃, the relative humidity of 35% of sawdust or rice husk dry to the relative humidity is 10%, the hot air temperature is not lower than 180 ℃, the discharging mouth temperature of 40-50 ℃.

- Fuel options: wood (wood), coal, steam, or electric heating.

- High drying intensity and low equipment investment. Airflow drying machine of large processing, water evaporation capacity, with small size and less investment, is incomparable to other drying machines.

- The high degree of automation and good product quality. During the drying process, the material is completely carried out in the pipeline, and the drying time is very short (only 2-10 seconds). During this period, the heat is mainly used for water evaporation, and the temperature of the material itself does not rise much, so the temperature has little influence on the product. Therefore, the product does not contact with the outside world, can be small pollution and good quality.

- Complete equipment supply and a heat source are optional. Users can configure corresponding equipment according to material conditions and process requirements.

- As for the selection of heating mode, due to the great adaptability of airflow drying machine, users can choose electric heating, steam heating, heat conduction oil heating, coal burning hot air furnace, gas hot air furnace, steam + electric heating, and other combined forms according to the conditions of the location of the equipment.

- The basic airflow dryer machine is suitable for loose, small viscosity granular materials, the materials with big viscosity need to be equipped with other corresponding devices.

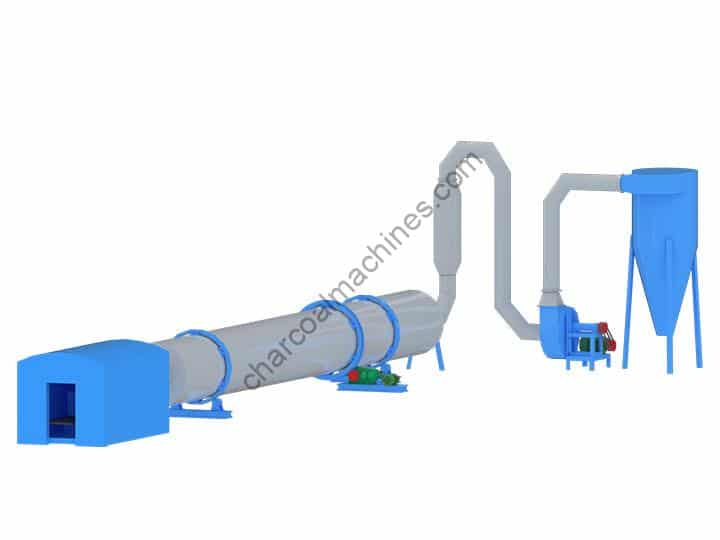

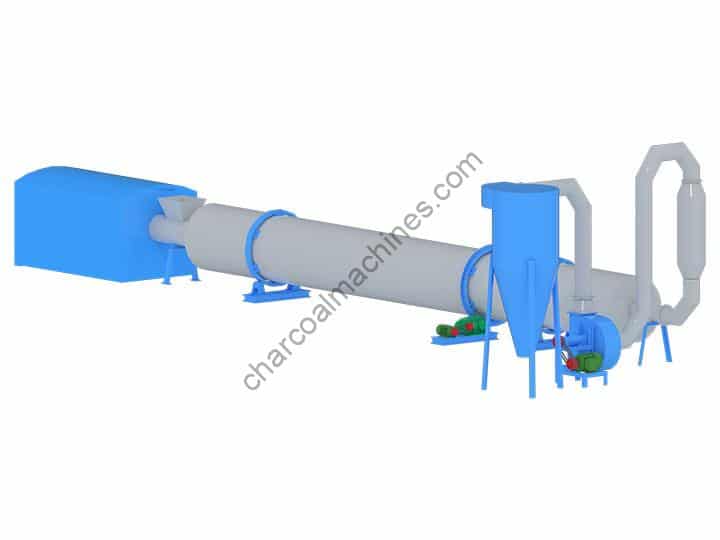

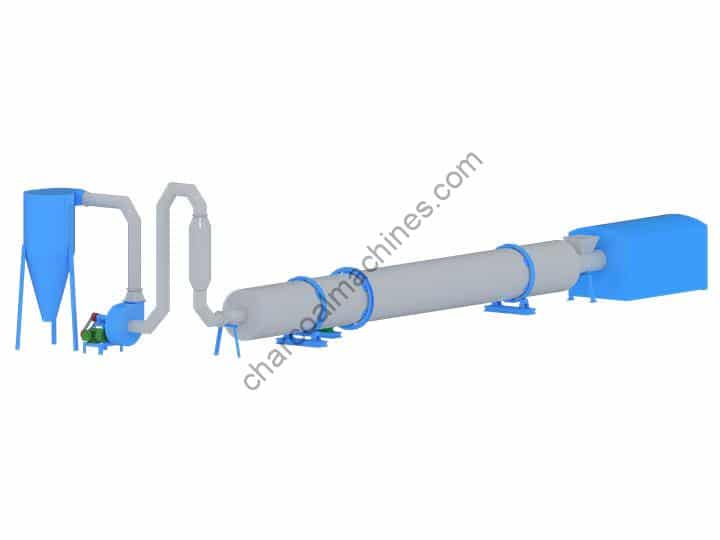

Rotary drum sawdust drying machine

Rotary sawdust dryer machine also can be called drum dryer and rotary dryer, which is the common drying equipment for mineral processing and charcoal production.

The rotary dryer machine has a compact structure that is mainly composed of a rotating body, lifting plate, gears, transmission device, supporting device, sealing ring, and other components.

When using this dryer machine, we usually should build or buy a small ignition stove in front of the drum body for providing hot air. Drum sawdust drying machine is widely used in food, animal feed, chemical industry, medicine, mining, and other industries.

What is the rotary dryer machine?

The drum rice husk dryer machine looks like just a cylinder slightly tilted in the horizontal direction. The powdery materials like sawdust or rice husk are added from the higher end, then hot air and materials flow into the middle cylinder. With the rotation of the cylinder itself, the material moves to the lower end with the lifting plate due to the action of gravity.

The inner wall of the cylinder is equipped with many lifting plates, which can lift up and sprinkle down the materials, and increase the contact surface between the material and the hot airflow, so as to improve the drying rate and promote the material to move forward. After drying, the materials are collected from the dust collector at the bottom of the rotary dryer machine.

Raw materials for drying with drum type sawdust dryer machine

Sawdust, rice husk, bamboo chips, peanut shells, coconut pieces, sesame rod, cotton rod, bean rod, vinasse slag, animal feed, and mineral materials like slag limestone, coal powder, slag, clay, and other materials.

Rotary dryer hourly working capacity ranges: 300kg/h-2000 kg/h.

Applications of the sawdust rotary dryer machine

The output of the drum dryer machine is different according to the moisture of the raw materials. The smaller the moisture content of the material, the larger the output of the dryer machine. The diameter of the rotary drum can be different and we can customize it for you. Besides, the rotation speed of the drum is adjustable.

This rice husk dryer machine is commonly used in the charcoal production line for drying the materials at the first step, then the dried materials which usually with a moisture content of less than 10% will be extruded by the sawdust briquette machine for making pini-kay. And the pini-kay can be further carbonized by the carbonization furnace.

Rotary drum sawdust drying machine in plants

Advantages of industrial rotary dryer machine

- Rotary dryer machine has a large processing capacity, less fuel consumption, and low drying cost.

- The drum dryer machine adopts the structure of an adjustable center tugboat, which is well-matched with the rolling ring and greatly reduces wear and power consumption.

- The rice husk dryer machine is specially designed to block wheel structure, greatly reduce the horizontal thrust caused by the tilt of the equipment. Strong overload resistance, cylinder running smoothly, high reliability.

- The sawdust drying equipment has the advantages of high-temperature resistance, can use high-temperature hot air for rapid drying of materials. Strong expansibility, the design takes into account the production margin, even if the output increases slightly, there is no need to replace the equipment.

- Rotary dryer machine lifting plate distribution and the angle design is reasonable, reliable performance, so the heat utilization rate is high, uniform drying, cleaning materials fewer times, easy maintenance.

Drum rice husk drying machine’s technical parameters

| NO. | MODEL | CAPACITY | POWER | FEED DIAMETER | DIMENSION |

| 1 | SL-D800 | 500kg/h | 2.2+7.5kw | ≤5mm | 15000*2600*3800mm |

| 2 | SL-D1000 | 1000kg/h | 3+15kw | ≤5mm | 16000*2600*3800mm |

| 3 | SL-D1200 | 2000kg/h | 3+18.5kw | ≤5mm | 18000*2800*4000mm |

| 4 | SL-D1500 | 3000kg/h | 5.5+22kw | ≤5mm | 19000*3000*4500mm |

Rotary sawdust dryer machine video

Hot Product

Continuous Charcoal Furnace for Biomass Charcoal Production

Continuous carbonization furnace is a new type of…

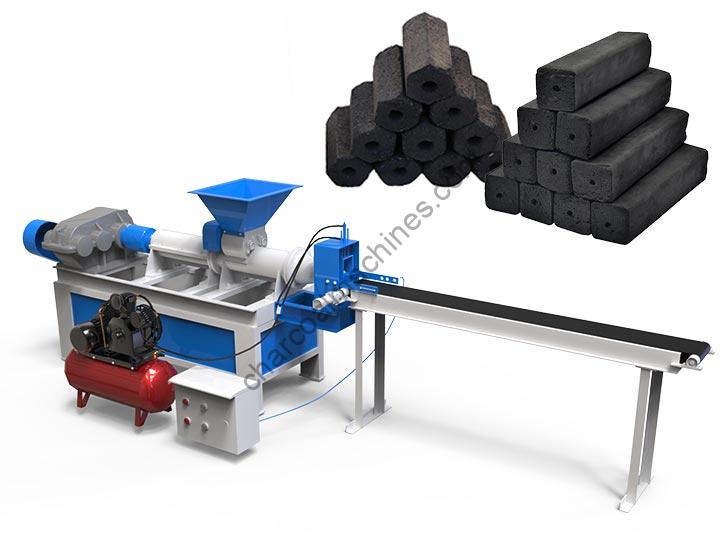

Charcoal Coal Briquettes Extruder Machine for Charcoal Plant

Charcoal briquette machine can extrude charcoal & coal…

Wood Sawdust Briquettes Production Line | Pini Kay Heat Logs Plant

The wood sawdust briquettes production line mainly extrudes…

Barbecue Charcoal Production Line | BBQ Briquettes Processing Plant

The barbecue charcoal production line mainly processes various…

Charcoal Machine & Production Line for Making BioCharcoal

The charcoal making machines can turn biomass wastes,…

Wood Shaving Machine for Animal Bedding

The wood shaving machine can process logs and…

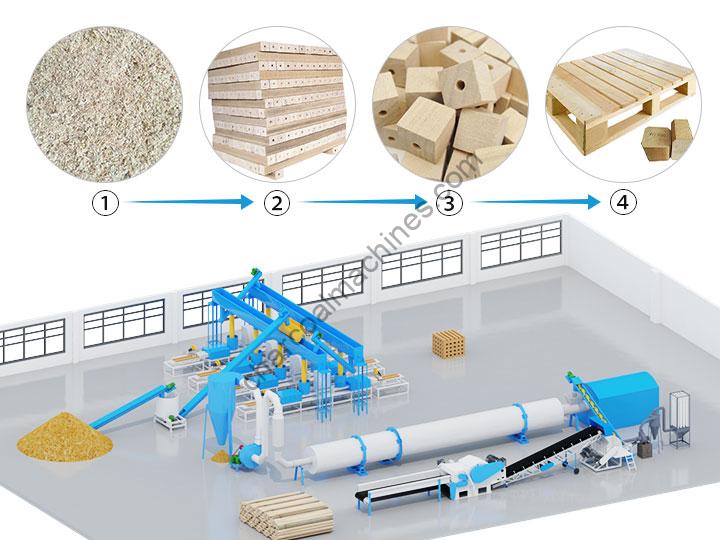

Wood Pallet Block Machine for Making Pallet Blocks

Commercial wood pallet block making machines can extrude…

Industrial Wood Pellet Machine for Sale

Wood pellet machine refers to the compression of…

Briquette Cutters for making briquette charcoal as required

The charcoal briquettes cutting machine is used to…

No Comments.