Complete Set of Wood Chip Block Machines Shipped to Indonesia

The industrial wood chip block machine can make compressed wooden blocks from wood powder, sawdust, wood chips, wood shavings, etc. under high temperature and high-pressure conditions. Many customers who are engaged in the pallet blocks production business process wood blocks for the production of wooden pallets or for sale. Last month, the complete set of wood chip block machines exported from our Shuliy factory to Indonesia was successfully installed and tested in the Indonesian factory, and now it has been officially put into production.

Raw materials from the Indonesia plant for making wooden blocks

Usually, the raw materials used to produce wooden blocks are wood chips, wood powder, and sawdust with low moisture content. The Indonesian customer said that the raw material in his factory is wet wood powder with a size below 5mm.

The customer thought that the wet wood powder could be directly used to produce blocks. We explained to the customer in detail the disadvantages of producing wood blocks with wet wood powder and recommended him use a tumble dryer to dry the moisture of the wet wood powder to less than 10%.

The Indonesian customer said that his factory is doing Melaka jigsaw puzzles, and the factory produces a large amount of wood powder every day. About 5 truckloads of wood flour need to be processed every day. So they plan to start the pallet blocks business and fully recycle the wood powder.

Details of Indonesia order of complete wood chip block machines

The Indonesian customer is quite familiar with the processing technology of wooden pallet blocks, and he can speak Chinese, so our communication with him is very timely and smooth. We communicated with the Indonesian customer in detail about the heat source of the sawdust dryer, the type and proportion of glue that needs to be added to make pallet blocks, the size of the wood blocks that the customer wants to process, sea freight and related customs clearance documents, etc.

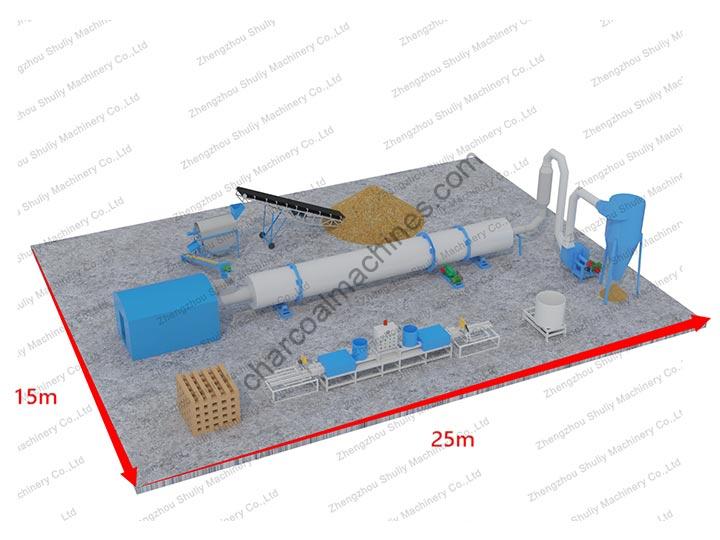

Among them, the most important point is that customers are not sure whether their factories can place a full set of wood chip block machines. In order to solve the customer’s questions, we asked the customer to send pictures of their own factory and collected data such as the size of the customer’s factory, and then asked our factory engineers to design a 3D layout drawing of the factory equipment according to the actual situation of the customer’s factory. In addition, we also provide customers with Chinese and English manuals for the machines they need.

The customer was very satisfied with the professionalism of our factory, and soon signed a contract with us. The Indonesian customer also said that the wood pallet blocks production line purchased by their factory this time is just a test project. If the production effect of the machine meets their expectations, they will order more wood chip block machines from our factory in the future.

Parameters of the wood pallet block line for Indonesia

| Item | Specifications | Qty |

| Belt conveyor | Model: SL-B-600 Power: 3kw Capacity: 1500-2500kg/h Weight: 600kg Dimension: 5*1.0*3.0m HS code: 40101900 | 1 |

| Rotary screening machine | Power: 1.5kw Dimension: 2.3*1.2m Diameter: 900mm HS code: 84741010 | 1 |

| Screw conveyor | Model:SL-S-320 Power:4kw Capacity:2000-3000kg/h Weight:500kg Dimension:5*0.4*1.7m HS code:8423290 | 1 |

| Rotary sawdust dryer machine | Model: SL-R-800 Power: 5.5kw Fan power: 7.5kw Capacity: 300-400kg/h(depends on the moisture of sawdust) Size: 0.8m in diameter, 10m in length HS code: 84193919 | 1 |

| Airlock device | Power:0.75kw Control the discharge speed HS code:84818099 | 1 |

| Sawdust & glue mixer | Power:7.5kw Dimension:1350*1000*1400mm Need 15% glue HS code: 847439 | 1 |

| Capacity: 4-5 m³/24h Temperature control method: PID power regulation and voltage regulation control Dimension: 4800*760*1300mm Weight:1200kg Final product: 70*90mm HS code: 847930 | 1 | |

| Automatic saw | Including 2 saw HS code: 846591 | 1 |

No Comments.