Round & Pillow Barbecue Charcoal Ball Press Machine

BBQ charcoal machine | Carbon ball press machine

Round & Pillow Barbecue Charcoal Ball Press Machine

BBQ charcoal machine | Carbon ball press machine

Features at a Glance

Barbecue charcoal ball press machine is a kind of mechanical equipment that compacts powdery materials into different shapes of solid briquettes. Usually, the charcoal or coal ball briquette machine is mainly used to press the charcoal and coal powder into ball shape briquettes.

In addition, the powdery materials with low moisture content like iron ore fines, metal dust, carbon black, cast iron dust, mill scale, manganese ore fines, fluorite powder, gypsum powder, ferrosilicon powder, nickel alloy, blast furnace ash, converter dust, sea sand powder and all kinds of mineral powder can also be pressed into briquettes with a certain shape by the BBQ charcoal press machine.

BBQ charcoal ball press machine’s basic features

Production capacity: 1-50T/h

Material requirements: The fineness of the material is below 5mm, and the moisture content is between 7-15%.

Material of pressure roller: high manganese alloy (high density, high finish, hardness of 56-58°).

Application areas: mainly used in coal, chemical, and other industries.

Applicable materials: coal powder, blue charcoal powder, coke powder, charcoal powder, iron ore powder, aluminum powder, iron powder, and other powdery materials.

Barbecue charcoal press machine for sale

Powdery coal or charcoal is extremely inconvenient to transport and use and will cause some environmental pollution. The use of charcoal or coal briquettes can reduce dust pollution and ease the transporting capacity and reduce the difficulty of transportation.

The bbq charcoal ball briquettes press machine is widely used in the molding of pulverized coal and charcoal, boiler materials, refractory materials, medical materials, and civil metallurgical materials.

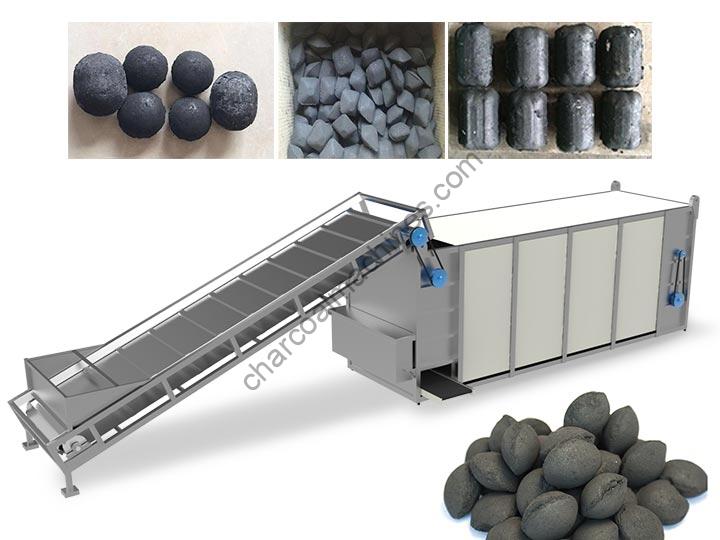

BBQ charcoal briquette machine is a common material pressing and forming equipment in the market at present. The charcoal or coal briquettes can be different shapes by changing with special molds, such as oval, pillow, round, egg, ball, column, and square.

We can also customize the shape for our customers. After briquetting, the coal briquettes and charcoal briquettes can be used for barbecue, civil heating, hookah smoking, industrial production, etc.

Structure of the BBQ charcoal press machine

1. Feeding part. The feeding part of the Barbecue charcoal press machine is mainly to achieve quantitative feeding to ensure that the material can evenly enter the machine’s pair of rollers. The screw feeding device is driven by an electromagnetic speed-regulating motor and is rotated by a belt pulley and a worm reducer to force the carbon powder and other materials into the main feed inlet.

Due to the constant torque characteristics of the electromagnetic speed-regulating motor, when the pressing amount of the screw feeder is equal to the amount of material required by the host, a constant feeding pressure can be maintained to stabilize the quality of charcoal briquettes. If the feeding amount is too large, the machine’s feeding device is electrically overloaded; if the feeding amount is too small, the charcoal briquettes will not be easy to form. Therefore, skilled operation techniques are an important condition to ensure the normal production of bbq charcoal.

2. Transmission part. The main drive system of the bbq charcoal machine is a motor-triangle belt-reducer-open gear-roller. The main engine is powered by an electromagnetic speed-regulating motor, which is transmitted to the driving shaft through a pin coupling via a belt pulley and a cylindrical gear reducer. The driving shaft and the driven shaft ensure synchronous operation through open gears. A hydraulic device is installed behind the passive bearing seat. The hydraulic protection device uses a hydraulic pump to drive high-pressure oil into the hydraulic cylinder to cause the piston to produce axial displacement. The front joint of the piston rod rests on the bearing seat to meet the production pressure requirements.

3. Forming part. The forming part of the charcoal ball press machine mainly refers to the host part, and its core part is the roller. When too much material is fed between the two pressure rollers or a metal block is entered, the piston rod of the hydraulic cylinder is overloaded, the hydraulic pump will stop, the accumulator will buffer the pressure change, the overflow valve will open to returning oil, and the piston rod will move. The position enlarges the gap between the pressure rollers so that hard objects pass through the pressure rollers, and the system returns to normal, which can protect the pressure rollers from damage.

Working principle of the barbecue charcoal briquette machine

Structurally speaking, the bbq charcoal machine is mainly divided into the feeding part, driving part, and forming part. The feeding part is mainly to achieve quantitative feeding to ensure that the material is evenly in the double roller space. The screw feeding device is driven by the electromagnetic speed-regulating motor and driven by the belt pulley and worm reducer to force the pressed material into the inlet.

The driving shaft and the driving shaft of the driving part are operated synchronously through the open gear. The forming part mainly refers to the core part named roller of this machine, which is a double roller structure. There is a hydraulic device behind the passive bearing seat.

Application advantages of the bbq charcoal ball press machine

- The BBQ charcoal machine has high forming pressure, the adjustable revolution of the main machine, and hydraulic protection device.

- Shuliy machinery provides a variety of professional barbecue charcoal press machines, the specific size and special shape models of the ball, and can customize the machine according to users’ needs.

- The quality of the finished coal is stable, the shape is not easy to be scattered and damaged, the density is large, and the combustion value is high.

- The charcoal balls press machine has a large production capacity, simple maintenance and operation, and no dust pollution in the production process.

Sample display of barbecue charcoal briquetting

Technical parameters of the bbq charcoal machine

| Model | Roller size(mm) | Spindle speed(r/min) | Power(kw) | Capacity(t/h) | Dimension(m) |

| SL-290-2 | 290*200 | 12-15 | 5.5-7.5 | 1-3 | 1.6*1.2*1.4 |

| SL-360-2 | 360*250 | 12-15 | 7.5-11 | 3-5 | 2.1*1.3*1.76 |

| SL-430-2 | 430*250 | 12-15 | 15-18.5 | 4-7 | 2.3*1.53*1.9 |

| SL-500-2 | 500*300 | 12-15 | 22-30 | 5-10 | 2.6*1.75*2.1 |

| SL-650-2 | 650*350 | 10-13 | 37-55 | 8-13 | 3.42*2*2.2 |

| SL-750-2 | 750*380 | 10-13 | 45-75 | 12-17 | 3.7*2.55*2.6 |

| SL-850-2 | 850*460 | 10-13 | 75-110 | 15-20 | 3.9*2.6*2.7 |

| SL-1000-2 | 1000*530 | 10-13 | 110-132 | 20-30 | 4*2.8*2.8 |

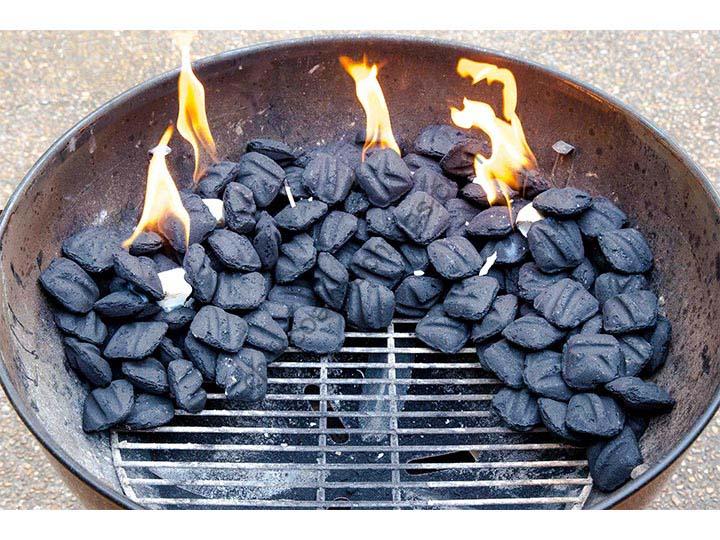

Great market demand for barbecue charcoal

The social demand for barbecue charcoal is increasing because people’s eating habits have changed a lot. With the improvement of living standards, people like fast food products more and more.

In particular, various types of barbecue and beer are already part of the lives of many young people. The rise of the barbecue industry is inseparable from the production of barbecue charcoal, so many processors engaged in the charcoal business will choose to produce high-quality barbecue charcoal.

BBQ charcoal briquette machine working video

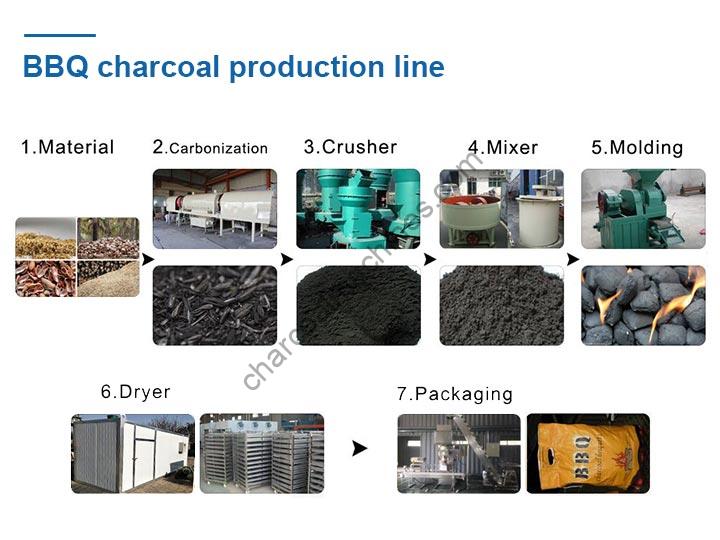

Large BBQ charcoal processing plant

For customers who want to invest in a large barbecue charcoal plant, a full set of charcoal processing solutions will be a huge help. Large-scale barbecue charcoal factories usually include carbonization, charcoal crushing, and stirring, and barbecue charcoal briquette.

Workflow of the bbq charcoal production line

Customer cases for barbecue charcoal production

This barbecue charcoal processing plant is located in Uganda and has an output of 20 tons per day. At present, the plant has been officially put into production and is applicable.

This is a barbecue charcoal plant located in the Philippines. The customer mainly produces heart-shaped barbecue charcoal for local sales. The customer was very satisfied with the production effect of the machine.

The barbecue charcoal production line exported to Morocco has been successfully put into production, with an output of 2 tons per day. This Moroccan customer mainly produces oval barbecue charcoal.

What materials can the barbecue charcoal making machine handle?

Barbecue charcoal machine can be used to press coal powder, iron powder, coking coal, aluminum powder, iron filings, iron oxide scale, carbon powder, carbon powder, slag, gypsum, tailings, sludge, kaolin, activated carbon, coke powder, etc. Powder, waste, waste residue, and other materials.

The production of cold-pressed briquettes of various metallurgical powders can be completed with a ball press. Such as coal powder, coke powder, various black non-ferrous metal ore powder, iron oxide scale, and dust removal ash, sludge, refractory materials, etc.

Usually, high-pressure briquettes press machine is often used to process dry powdery materials, such as oxide scale, steel slag, iron fine powder, aluminum ash powder, silicomanganese powder, and so on.

The low-pressure briquettes press machine is suitable for processing wet powdery materials. Such as dust removal ash, pool mud, sludge, coal powder, charcoal powder, etc. That is, it is necessary to add a proper proportion of water or other liquid binders to the material.

To process different materials, the pressure and model of the selected briquettes press machine are different. Our factory can recommend suitable machine models for customers according to their raw materials and processing needs.

How much does a BBQ charcoal press machine cost? –barbecue charcoal machine price

The prices of barbecue charcoal machines on the market are quite different. This is because the manufacturing technology of different manufacturers and the cost of raw materials used are different.

There are usually many types of BBQ charcoal machines, with a processing capacity between 1 ton and 50 tons. The larger the processing capacity, the larger the model of the machine, and the higher its price. In addition, the quality of the parts of the charcoal ball press machine is different, and the price will also vary.

Generally, for small and medium-sized charcoal factories, the investment cost of a barbecue charcoal machine is about 3000-5000 USD.

But if the customer purchases a series of supporting equipment at the same time as the bbq charcoal machine, such as carbonization equipment, charcoal crushing and mixing equipment, barbecue charcoal dryer, barbecue charcoal packaging machine, etc., the total price will be higher.

What are the wearing parts of the charcoal ball press machine?

The wearing parts of the charcoal ball press machine are mainly its geared motor and pressure roller. In fact, the service life of the motor and the pressure roller are very long, but if the customer does not use the machine according to the correct operation method, it is easy to cause damage to the motor.

In addition, the pressure roller of the barbecue charcoal machine is also a vulnerable part, and long-term use will cause a certain degree of wear on the pressure roller (ie mold). Therefore, we usually recommend customers buy an extra set of molds for later replacement. If customers repurchase corresponding accessories from us, we usually provide discounted prices to repay customers.

How do we arrange the delivery of the bbq charcoal briquette machine?

Our factory has a certain amount of inventory for various types of barbecue charcoal press machines, so we can arrange the delivery on time after receiving the customer’s order, usually within a week. If the equipment required by the customer needs to be customized, the delivery time is about one month. The shipping methods of the equipment are mainly by sea, air, and land. Our factory can recommend the most suitable shipping method to customers according to their location.

How to maintain the charcoal ball press machine?

In the process of using the barbecue charcoal machine, customers need to maintain and maintain the machine reasonably, so as to better ensure the high-quality and efficient work of the briquette machine. Extend the working life of the bbq charcoal making machine and improve the working efficiency of the bbq charcoal briquetting machine.

- Check the tightness of the whole machine. Check the oil volume of the equipment, strengthen the lubrication of each lubrication point of the ball press, and use the most correct application method to use the grease for the lubrication work.

- Keep the barbecue charcoal briquette machine equipment clean during use, and check all parts in time to ensure that there is no looseness or damage to the parts during use.

- If the running-in period is over, the barbecue charcoal machine should be maintained compulsorily, and the oil should be replaced and maintained in time. The maintenance work during the running-in period of the charcoal briquettes press machine during the first three months of use is also very important. Only correct and regular maintenance of the briquette machine can improve the working efficiency of the briquette machine and reduce the labor intensity of the manpower.

How to improve the production efficiency of barbecue charcoal?

For barbecue charcoal processors, it is very important to improve the production efficiency of BBQ charcoal and save production costs. Generally, using skilled workers to operate the bbq charcoal machine will avoid most machine failures. In addition, regular maintenance of the equipment and adding lubricating oil to the equipment will extend the service life of the equipment.

Contact Shuliy now!

Thank you for reading this article!

If you have any questions about the barbecue charcoal machine, please call our website customer service phone number (WhatsApp) directly.

And if you find it useful or interesting, please bookmark this article or share it with those in need.

Hot Product

Charcoal Machine & Production Line for Making BioCharcoal

The charcoal making machines can turn biomass wastes,…

Briquette Cutters for making briquette charcoal as required

The charcoal briquettes cutting machine is used to…

Charcoal Coal Crusher | Charcoal Powder Grinder Machine

The charcoal crusher machine can mainly pulverize various…

Raymond Mill for Grinding Fine Charcoal Powder

Raymond mill is mainly used as a piece…

Hookah Charcoal Machine to Make Round & Cube Shisha Charcoal

Shuliy shisha charcoal press machine is designed according to…

Wood Pallet Block Machine for Making Pallet Blocks

Commercial wood pallet block making machines can extrude…

Compressed Wood Pallet Machine for Molded Pallet Production

The compressed wood pallet machine is a piece…

Round & Pillow Barbecue Charcoal Ball Press Machine

Barbecue charcoal press machine can make compressed charcoal…

Honeycomb Coal Briquette Press Machine

The honeycomb coal briquette machine can press the pulverized charcoal powder…

6 comments