High-Efficiency Sawdust Briquette Machine for Sale

Transform sawdust, rice husks, and wood waste into valuable fuel briquettes. Our robust sawdust briquette machine offers a high ROI by reducing disposal costs and creating a new revenue stream. Get your free quote today!

High-Efficiency Sawdust Briquette Machine for Sale

Transform sawdust, rice husks, and wood waste into valuable fuel briquettes. Our robust sawdust briquette machine offers a high ROI by reducing disposal costs and creating a new revenue stream. Get your free quote today!

Features at a Glance

Are you struggling with mounting piles of sawdust, wood shavings, or agricultural waste? Instead of paying for costly disposal, what if you could transform that waste into a valuable, high-demand product? Our industrial sawdust briquette machine (also known as a biomass briquette press or pini kay extruder) is the ultimate solution. It uses immense pressure and heat to compress loose biomass into dense, high-energy fuel logs, creating a profitable new opportunity for your business.

Why Invest in a Sawdust Briquette Machine? Your Path to Profitability

Investing in a briquetting press is more than just buying a piece of equipment; it’s a strategic move to boost your bottom line and enhance sustainability. Here’s how our machine delivers exceptional value:

- Generate a New Revenue Stream: Stop throwing money away on waste. Convert sawdust, rice husks, and other biomass into high-density briquettes that can be sold as a premium, eco-friendly fuel for heating or industrial use.

- Drastically Reduce Costs: Slash your waste disposal fees and transportation expenses. Our machine can reduce your material volume by up to 90%, freeing up valuable storage space and simplifying logistics.

- Achieve Energy Independence: Hedge against volatile energy prices. Use the briquettes you produce to fuel your own boilers or heating systems, significantly cutting your operational energy costs. Did you know? Just 2kg of wood briquettes can replace 1 liter of heating oil.

- Enhance Safety and Cleanliness: Compressing loose, dusty materials into solid blocks dramatically reduces airborne dust, minimizing the risk of dust explosions and creating a cleaner, safer working environment.

What Raw Materials Can Be Processed?

Virtually any biomass waste containing natural lignin can be turned into valuable briquettes. The key is to ensure the material is properly sized and dried. Our machine excels at processing:

- Wood Waste: Sawdust, wood chips, wood shavings, sanding dust, shredded pallets.

- Agricultural Residues: Rice husks, corn stalks, crop straw, sugarcane bagasse, coconut shells, peanut shells.

- Forestry Waste: Shrub branches, bamboo powder, tree bark.

Material Requirements for Optimal Results

- Size: For best results, raw materials should be crushed to a size of less than 8mm (5mm is ideal). Need a reliable crusher? Check out our wood crusher machine.

- Moisture: The moisture content must be controlled between 8% and 12%. If your material is too wet, our efficient sawdust dryer machine can quickly prepare it for briquetting.

How Our Sawdust Briquette Machine Works

Our machine makes briquette production simple and efficient. The process is fully automated and requires minimal supervision. Here’s a step-by-step breakdown:

- Feeding: Prepared raw material is fed into the machine’s hopper. A screw conveyor pushes the material into the pre-charging chamber.

- Heating & Compressing: The material enters the main pressing chamber, which is surrounded by heating rings. As the temperature rises (typically to 280-380°C), the natural lignin in the biomass softens. A powerful screw propeller then applies immense pressure, compressing the material.

- Forming: The compressed, heated material is extruded through a specially designed molding die, forming it into a dense, solid briquette with a central hole (which aids in even combustion).

- Cooling & Cutting: The finished briquettes exit the machine and are then cooled and can be cut to a desired length, ready for packaging, sale, or further processing into charcoal.

Choose the Right Model for Your Needs

We offer several models to match your specific production requirements and budget. Whether you’re a small workshop or a large-scale industrial operation, we have the perfect machine for you.

| Model | Capacity (kg/h) | Motor Power | Key Features |

|---|---|---|---|

| SLIII-1 | 160-200 | 15 kW | Ideal for small-scale operations and startups. Compact and efficient. |

| SLIII-2 | 220-260 | 18.5 kW | Our most popular model, offering a great balance of output and power consumption. |

| SLIII-3 | 280-320 | 22 kW | Designed for high-volume industrial production and continuous 24/7 operation. |

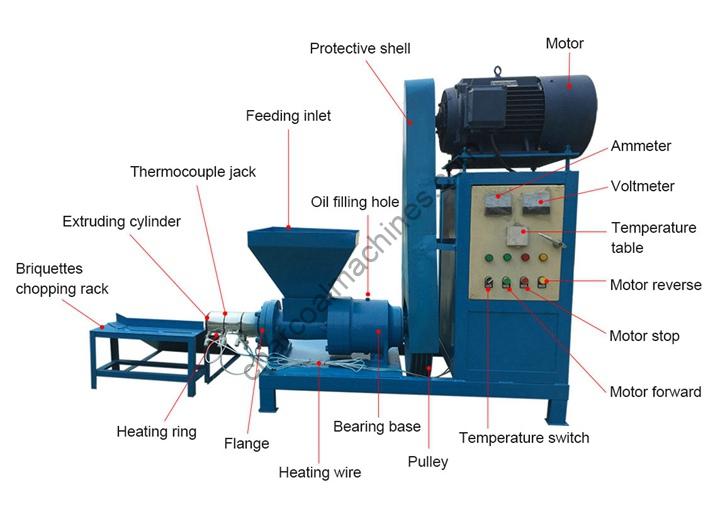

Key Components: Engineered for Durability

We understand that uptime is critical. That’s why every component of our machine is built with high-quality, wear-resistant materials to ensure long service life and minimal maintenance.

Wear-Resistant Screw Propeller

The heart of the machine. Made from high-grade alloy steel and treated for extreme hardness, the propeller tip is specially coated to withstand constant abrasion, ensuring consistent pressure and output.

High-Efficiency Heating Rings

Our robust heating system ensures rapid and stable temperature control, which is crucial for forming high-quality, crack-free briquettes. They are designed for easy replacement to minimize downtime.

Durable Forming Cylinder

Crafted from a high-wear-resisting steel composite, the forming cylinder (mold) maintains its shape and integrity even under extreme pressure, guaranteeing uniform briquette size and density over thousands of hours of operation.

Customer Success Stories

Don’t just take our word for it. See how businesses around the world are succeeding with our equipment.

Nigeria: A client with 3 years in the charcoal business upgraded his entire operation with our complete production line, including crushers, dryers, and multiple briquette machines, to meet soaring local demand. Read the full story.

Tanzania: A customer purchased our rice husk briquette machine to turn agricultural waste into profit. He now supplies high-calorific value pini kay briquettes to local restaurants, hotels, and bathhouses as a boiler fuel. Learn more.

Briquettes making machine video

Frequently Asked Questions (FAQ)

Q: What is the return on investment (ROI) for a sawdust briquette machine?

A: The ROI is typically very high and fast. Many of our clients see a return on their investment within 12-18 months, thanks to savings on disposal costs and revenue from briquette sales. We can help you calculate a precise ROI based on your specific situation.

Q: Do I need other machines besides the briquette press?

A: It depends on your raw material. If your material is too large or too wet, you will need a wood crusher and a sawdust dryer. We can provide a complete, turnkey solution for your entire production line.

Q: Can these briquettes be turned into charcoal?

A: Absolutely! The briquettes produced by our machine are the ideal feedstock for making high-quality BBQ or industrial charcoal. They can be carbonized in our carbonization furnace to create a product with even higher market value.

Q: Do you provide installation and training?

A: Yes, we provide comprehensive support. We offer detailed installation manuals, video guides, and remote technical assistance to ensure your machine is set up correctly and your team is trained for safe and efficient operation. For detailed operational steps, you can consult our online operation manual.

Ready to Turn Your Waste into a Revenue Powerhouse?

Stop letting waste eat into your profits. Contact our team of experts today. We’ll help you select the perfect machine, configure a complete production line, and provide a detailed, no-obligation quote. Let’s build a more profitable and sustainable future for your business together.

Hot Product

Biomass Wood Pellet Production Line

The biomass wood pellet production line is an…

Hookah Charcoal Machine to Make Round & Cube Shisha Charcoal

Shuliy shisha charcoal press machine is designed according to…

Vertical Carbonization Furnace For hardwood Charcoal Production

The airflow hoisting carbonization furnace is currently the…

Wood Shaving Machine for Animal Bedding

The wood shaving machine can process logs and…

Continuous Charcoal Furnace for Biomass Charcoal Production

Continuous carbonization furnace is a new type of…

Flue Gas Purification Equipment

Flue gas purification In the past, due to…

Shisha (Hookah) Charcoal Production Line | Briquette Packaging Dryer Plant

The automatic shisha(hookah) charcoal production line is the…

Wood Debarker Machine for Peeling Logs

Wood debarker machine, also known as the log…

Thermal Shrink Packing Machine for Packaging Sawdust Pini Kay Briquettes

This automatic thermal shrink packing machine can be…

4 comments