Charcoal Coal Briquettes Extruder Machine for Charcoal Plant

Briquette charcoal extruder | charcoal briquette press

Charcoal Coal Briquettes Extruder Machine for Charcoal Plant

Briquette charcoal extruder | charcoal briquette press

Features at a Glance

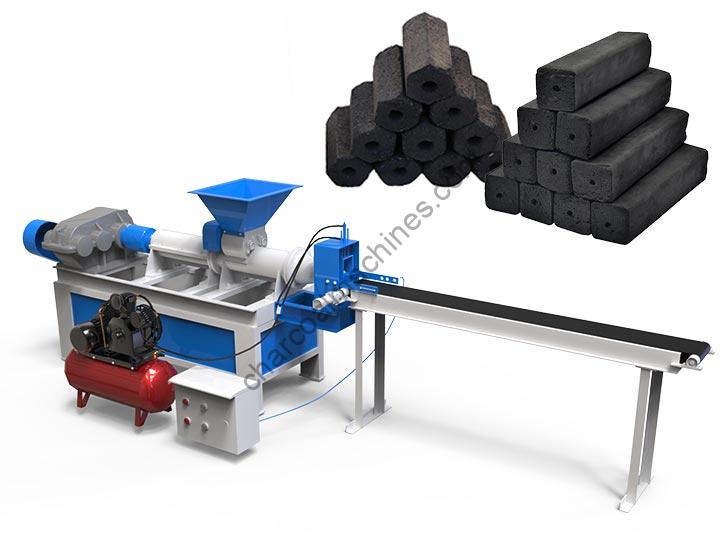

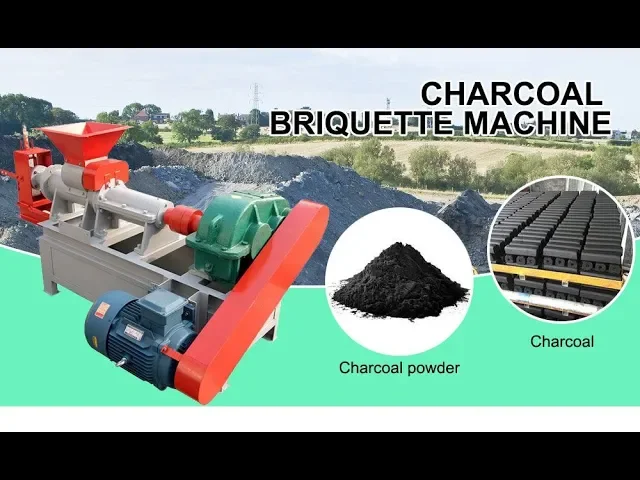

The charcoal briquette machine, also known as coal & charcoal extruder machine and charcoal briquettes making machine, which is the special equipment for briquettes production. The charcoal briquettes makers are composed of the base, bearing base, spiral shaft, discharge port, and extruding molds.

The coal briquette machine compresses the prepared pulverized charcoal powder into a predetermined shape. These briquettes have certain strengths by using screw extrusion and cutting devices.

The charcoal briquettes extruder machine is widely used for the molding of charcoal powder, coal foam, coal gangue, lignite, anthracite, iron powder, aluminum powder, and other raw materials. And it is often used with the wheel grinder mixer and briquettes cutting machine, and it is the common equipment in charcoal briquettes production line.

Main structure of the charcoal briquettes making machine

The screw blade and head of the coal briquette machine are made of high wear-resisting casting alloy material, which can increase the service life of these wearing parts by 3 to 4 times.

The whole base is used in the charcoal briquette machine, all parts of the machine are installed on the same level datum, and the work is stable and reliable.

The motor and the reducer adopt the belt flexible transmission, when the working load is overloaded, the belt skidding can well protect the motor and other machinery, and improve the working safety of the machine.

Industrial coconut charcoal briquettes extruder machine video

Charcoal briquettes extruder machine for sale

This charcoal briquette machine is a piece of environmentally friendly equipment that can use coal or charcoal powder to make high-quality coal and charcoal briquettes with different shapes.

This charcoal briquettes making machine is very practical for making shisha or hookah charcoal briquettes in a high-efficient way. Shapes of the final charcoal or coal briquettes can be round, square, hexagon, quincunx, and so on.

We can also customize different molds for you according to the customers’ requirements. Besides, the length of the charcoal briquettes is also adjustable which is up to our customers’ actual demands.

-

briquettes -

briquette machine -

briquette machine 2 -

briquette machine 3 -

briquette machine 4 -

briquette machine 5 -

briquette machine 6 -

briquette machine 7 -

briquette machine 8 -

briquette machine 9 -

briquette machine 10

Components of the coal briquette extruder machines

The charcoal or coal powder for charcoal briquette making should be mixed with a proper amount of binder which is required to be mixed.

Coconut shells, rice husk, wood branches, peanut shells, palm kernel shells, and other biomass materials can be carbonized by the carbonization furnace first. Then we can use a series of charcoal machines like charcoal crushers and grinders to make fine charcoal powder.

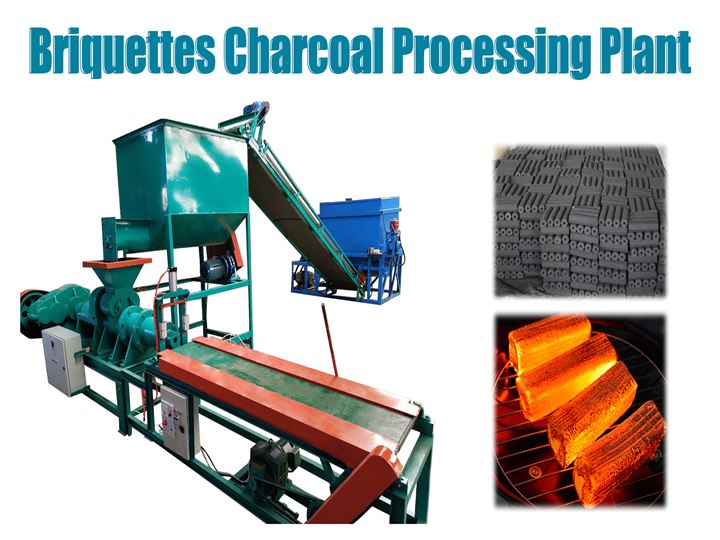

The charcoal briquette production equipment for sale is a screw-type briquette extruding machine, which is economical and increases the calorific value of the charcoal by shaping it into the form of briquettes.

The density of final charcoal briquettes from the charcoal briquettes making machine is very high so that it can burn a long time. The output capacity of charcoal briquette extruder machines ranges from 500kg-1000kg per hour.

Application of charcoal briquette machine

Coal or charcoal briquette machine is widely used in the chemical industry, smelting, gas, ceramics, thermal power plant, ammonia fertilizer plant, and other industries, also widely used in the coal production line.

The coal or charcoal briquettes making machine mainly compacts the pulverized coal material which has been crushed by the coal crusher and stirred by the wheel grinding machine into a certain shape coal bar.

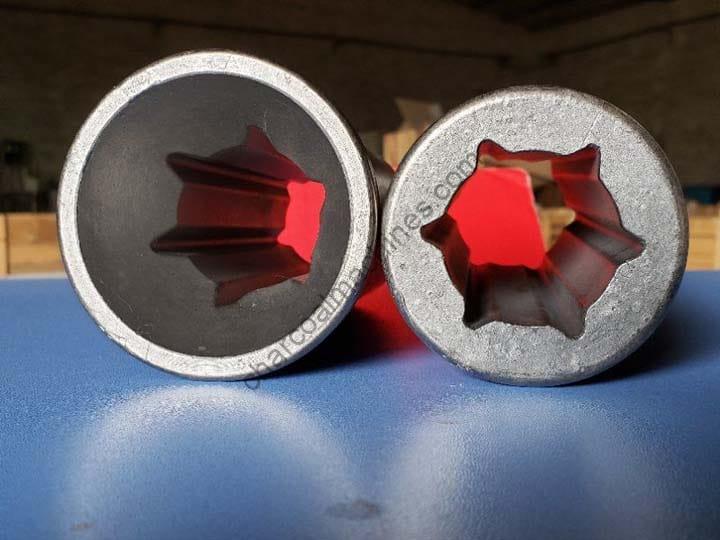

There are various forms of molds at the outlet of the coal briquette machine, which can be changed at will according to the specific requirements and is very convenient for loading and unloading.

The charcoal extruding machine can be used for pressing different molds of briquettes by replacing matched molds. The customers can purchase a complete machine with many kinds of molds, then the machine can be multipurpose, and the customers can save capital.

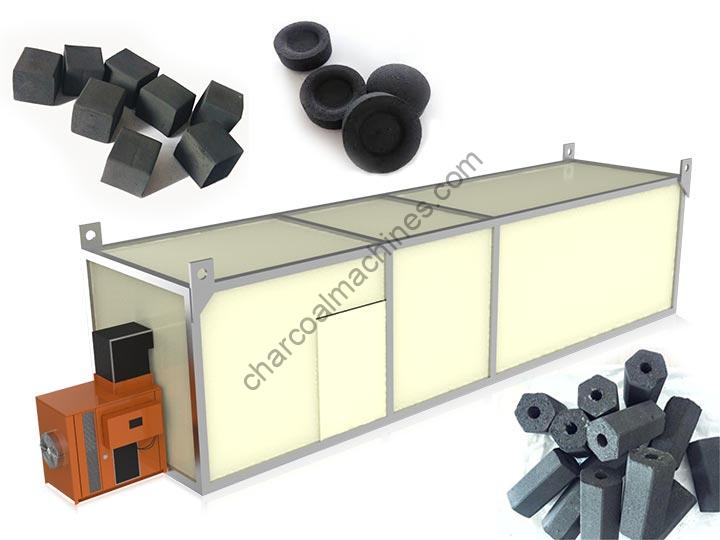

We can also provide other kinds of charcoal briquette machines that can produce honeycomb charcoal or coal briquettes, cubic or round shisha or hookah charcoal briquettes, and bbq charcoal briquettes. This commercial charcoal briquette machine is often used in charcoal processing plants of various sizes to produce charcoal products of various specifications, such as barbecue charcoal and hookah charcoal.

Main features of charcoal briquuettes making machine

- There are plum shape, triangle shape, a quadrilateral shape, diamond shape, and other styles of coal briquette machine mold, which can be customized according to customer requirements.

- Smooth operation, low noise, low wear, and long service life; High output, low energy consumption, high performance, high finished product strength.

- The fuselage steel plate is made of a national standard steel plate, which improves the service life of the whole machine, facilitates repair, reduces consumption, ensures safe and reliable operation, and ensures quality.

- The core accessories of the coal briquette machine are reamer. Reamer is made of alloy, which is wear-resistant, durable, efficient and energy-saving and widely used.

- The equipment is simple in structure, simple in operation, and small in size, which reduces the area occupied and saves the investment.

Briquettes extruder machine display of Shuliy factory

Coal briquette machine’s technical parameters

| Model | Motor(kw) | Output (t/h) | Weight(t) | Rotation rate (rpm) | Dimension (mm) |

| SL-140 | 11 | 1~2 | 1.2 | 60 | 1900×1100×1170 |

| SL-180 | 22 | 2~3 | 2.5 | 60 | 2210×1370×1440 |

| SL-300 | 90 | 5~6 | 4.5 | 132 | 3605×1025×955 |

| SL-450 | 220 | 9~12 | 7.5 | 132 | 5130×1520×1480 |

Working process of the coal briquette machine

In fact, the main function of the coal briquette machine is to make briquettes from carbon powder under a certain squeezing force. However, the carbon powder needs to be processed accordingly before being squeezed.

For example, we need to add a certain amount of binder to the carbon powder and ensure that the carbon powder maintains a certain moisture content. Moreover, after coal briquettes are made, we still need to cut them into briquettes of uniform length with the help of the briquettes cutting machine.

In short, the working process of the charcoal briquette machine includes charcoal crushing, charcoal powder grinding, binder mixing, charcoal briquettes extruding, briquettes cutting, etc.

Charcoal briquette machine working video

Customer cases of the charcoal briquettes extruder machine

A customer from Manila, Philippines ordered a briquettes extruder machine with a capacity of 500kg/h. This customer mainly uses this machine to produce square charcoal briquettes.

The Philippine customer personally visited our charcoal machine factory and ordered a briquettes extruder machine that can make cube hookah charcoal. The Philippine customer partnered with his Turkish friend to start a hookah charcoal production business. The raw material is coconut shell.

Why we got so many Indonesian orders for briquettes extruder machines?

In the past 10 years, we have exported a large number of charcoal briquettes extruder machines to many Southeast Asian countries, such as Malaysia, the Philippines, and Indonesia.

Among them, the Philippines and Indonesia are the two countries with the most exports. We can sell more charcoal briquette machines to Indonesia and other countries, in addition to the great local market demand, because our briquette extruders are too cost-effective.

Factors affecting the service life of coal briquette machine

Some users usually do not pay attention to following the correct operating instructions when using coal briquette making machines. The consequence of this is that the briquettes have poor molding effects and low output. It can also cause the briquette extruder machine to malfunction.

Therefore, the main factor affecting the service life of the coal briquette machine is whether the user can operate the machine correctly. Our factory will usually send customers detailed operating instructions for charcoal briquette machines and correct operation instruction videos to help customers quickly master the method of using briquette machines.

How is the charcoal briquette machine price?

The price of the charcoal briquette machine varies from manufacturer to manufacturer. Usually, foreign customers also add freight when buying a commercial briquette extruder machine, so the price is higher.

Taking into account the customer’s actual production and reducing the customer’s production cost, we usually increase the price of the most cost-effective briquette machine to the customer.

The factors affecting the price of briquettes extruder machines are usually the quality of the machine and the efficiency of production. Therefore, customers should not only pay attention to the price of the machine when purchasing a coal briquette machine but should pay attention to the machine’s performance.

Maintenance of the charcoal extruder machine

In order to make the commercial briquettes extruder machine have a longer service life, the user should not only use the machine correctly according to the operating instructions but also know how to perform daily maintenance on the briquette machine.

The maintenance of the coal briquettes extruder machine generally requires regular tightening of its screws, adding lubricating oil to the bearings of the machine, and regular thorough cleaning.

Why invest in the briquettes production business?

The charcoal briquettes production business is popular because the industry is indeed profitable. The traditional lump charcoal production method has been gradually replaced by modern charcoal processing methods.

After briquetting, charcoal can be processed into various shapes and specifications, which makes charcoal more attractive in appearance and more versatile. In the process of processing charcoal briquettes, charcoal processors also increase the added value of their products and thus obtain higher profits.

Factors affecting the forming of charcoal briquettes

In the production process of Charcoal briquettes, there are some factors that will affect the molding effect of briquettes, and users need to pay attention to them when using them. The first is the addition of adhesives. The proportion of binder added needs to be strictly controlled.

Secondly, it is necessary to ensure the fineness of the carbon powder. If the particles of carbon powder or coal powder are too large, the surface of the produced briquettes will be rough.

In addition, the dry humidity of the carbon powder should also be controlled. If the water content of the charcoal powder is too low, the production efficiency of briquettes will be slow and it is not easy to form.

Contact Shuliy now!

Thank you for reading this article!

If you have any questions about the charcoal briquette machine, please just call our website customer service phone number (WhatsApp) directly. We can provide detailed production solutions and quotations soon.

And if you find it useful or interesting, please bookmark this article or share it with those in need.

Hot Product

Shisha (Hookah) Charcoal Production Line | Briquette Packaging Dryer Plant

The automatic shisha(hookah) charcoal production line is the…

Continuous Charcoal Furnace for Biomass Charcoal Production

Continuous carbonization furnace is a new type of…

Wood Hammer Mill for Recycling Wood Scraps

Wood hammer crusher mill can crush wood chips,…

Honeycomb Coal Briquette Press Machine

The honeycomb coal briquette machine can press the pulverized charcoal powder…

Briquette Cutters for making briquette charcoal as required

The charcoal briquettes cutting machine is used to…

Horizontal Charcoal Furnace for biochar production

The horizontal charcoal furnace is the high efficient…

Drum Wood Chipper for Wood Chips Mass Production

The wood chipper shredder machine mainly can be…

Wood Debarker Machine for Peeling Logs

Wood debarker machine, also known as the log…

Charcoal Briquettes Packaging Machine for Packing Barbecue Charcoal Quantitatively

This quantitative charcoal briquettes packaging machine can be…

2 comments